Regeneration method for modified zeolite molecular sieve amination catalyst

A modified zeolite and catalyst technology, applied in molecular sieve catalysts, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., to achieve the effect of solving carbon deactivation, reducing diffusion resistance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

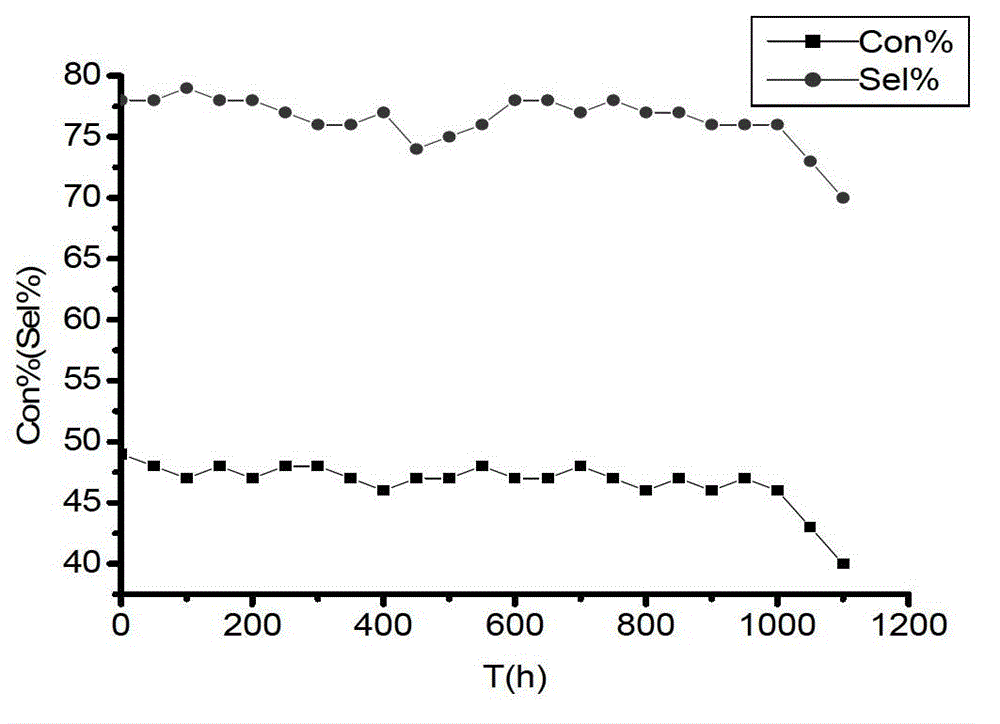

Embodiment 1

[0027] 1. Modified zeolite molecular sieve amination catalyst regeneration treatment method

[0028] a) Add the deactivated modified zeolite molecular sieve amination catalyst into deionized water according to the solid-to-liquid ratio of 1:4, slowly add an appropriate amount of citric acid under strong stirring until the pH value of the reaction suspension reaches 4-5, and heat to reflux 2h, filter, wash to neutral, and dry.

[0029] b) The coke-dissolving modified zeolite molecular sieve amination catalyst obtained in step a) is used at 260° C. 2 / O 2 The mixed gas is used for low-temperature charcoal regeneration, and the exothermic temperature difference in the process of regeneration charcoal is controlled to be ≤5°C until no CO is detected in the reaction tail gas. 2 generated, the temperature is raised to 400°C to continue to use N 2 / O 2 The mixed gas is used for high-temperature charcoal regeneration, and the exothermic temperature difference in the regeneration c...

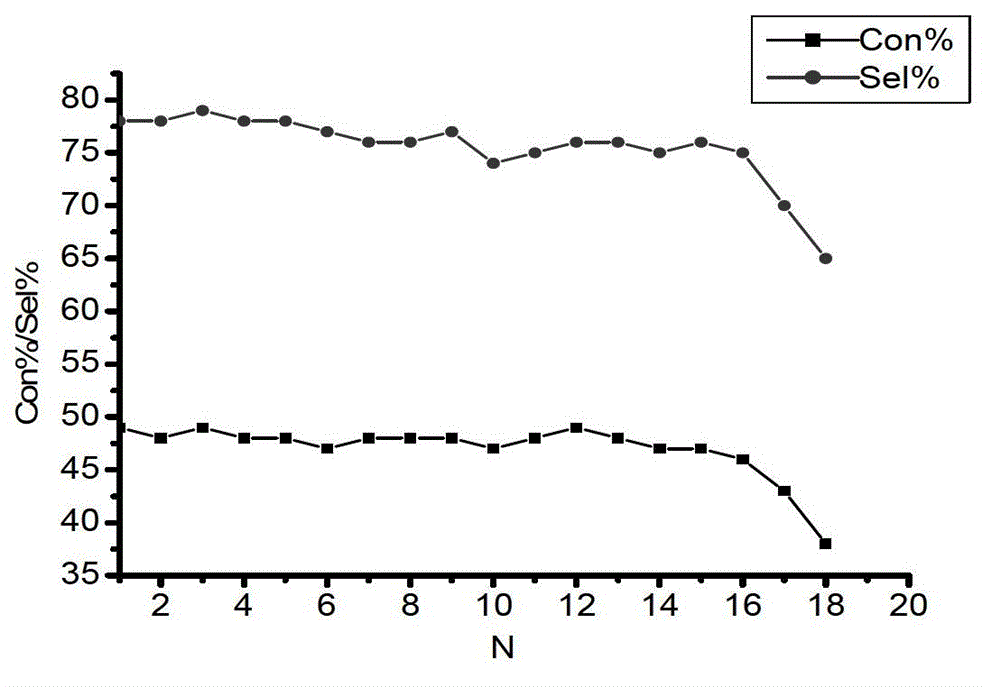

Embodiment 2

[0037] 1. Modified zeolite molecular sieve amination catalyst regeneration treatment method

[0038] a) Add the deactivated modified zeolite molecular sieve amination catalyst into deionized water according to the solid-to-liquid ratio of 1:4, slowly add an appropriate amount of oxalic acid under strong stirring until the pH value of the reaction suspension is 4-5, heat and reflux for 2 hours , filtered, washed to neutral, and dried.

[0039] b) The coke-dissolving modified zeolite molecular sieve amination catalyst obtained in step a) is regenerated at 260° C. using a mixed gas of N2 / O2 to burn charcoal at a low temperature, and control the exothermic temperature difference in the process of regenerated charcoal ≤ 5° C. to No CO detected in the reaction tail gas 2 generated, the temperature is raised to 400°C to continue to use N 2 / O 2 The mixed gas is used for high-temperature charcoal regeneration, and the exothermic temperature difference in the regeneration charcoal b...

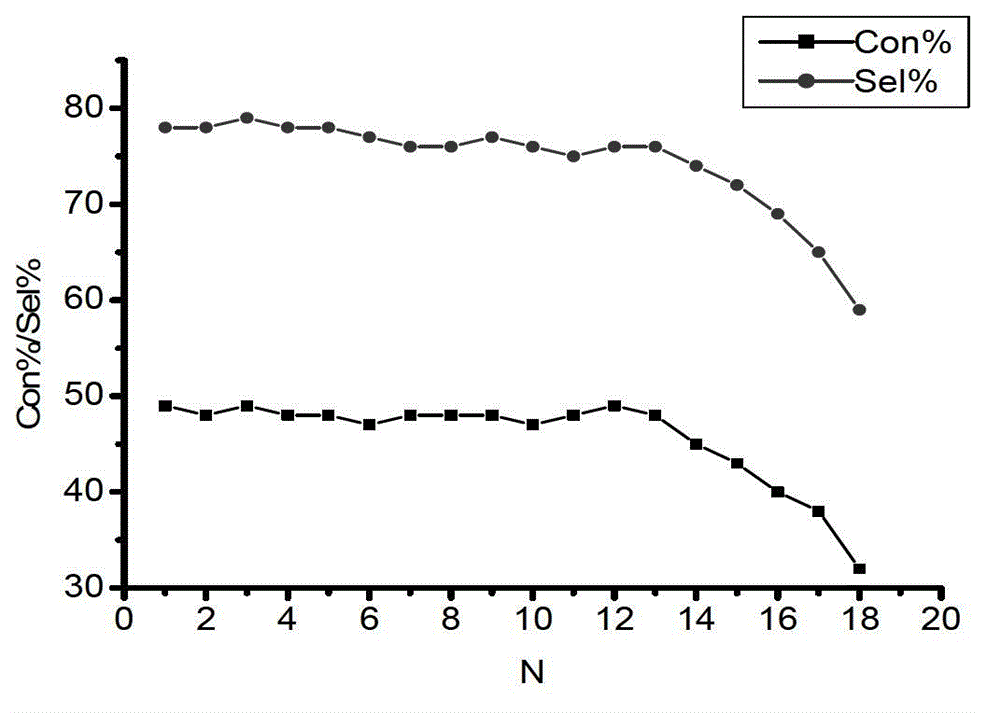

Embodiment 3

[0047] 1. Modified zeolite molecular sieve amination catalyst regeneration treatment method

[0048] a) Add the deactivated modified zeolite molecular sieve amination catalyst into deionized water according to the solid-to-liquid ratio of 1:4, slowly add an appropriate amount of malic acid under vigorous stirring until the pH value of the reaction suspension reaches 4-5, and heat to reflux 2h, filter, wash to neutral, and dry.

[0049] b) The coke-dissolving modified zeolite molecular sieve amination catalyst obtained in step a) is used at 260° C. 2 / O 2 The mixed gas is used for low-temperature charcoal regeneration, and the exothermic temperature difference in the process of regeneration charcoal is controlled to be ≤5°C until no CO is detected in the reaction tail gas. 2 generated, the temperature is raised to 400°C to continue to use N 2 / O 2 The mixed gas is used for high-temperature charcoal regeneration, and the exothermic temperature difference in the regeneration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com