Ultrahigh strength open section hot roll forming process and device

An ultra-high-strength, forming technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large springback and poor plasticity of high-strength steel, and achieve quality degradation, high production efficiency, and avoidance of residual stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

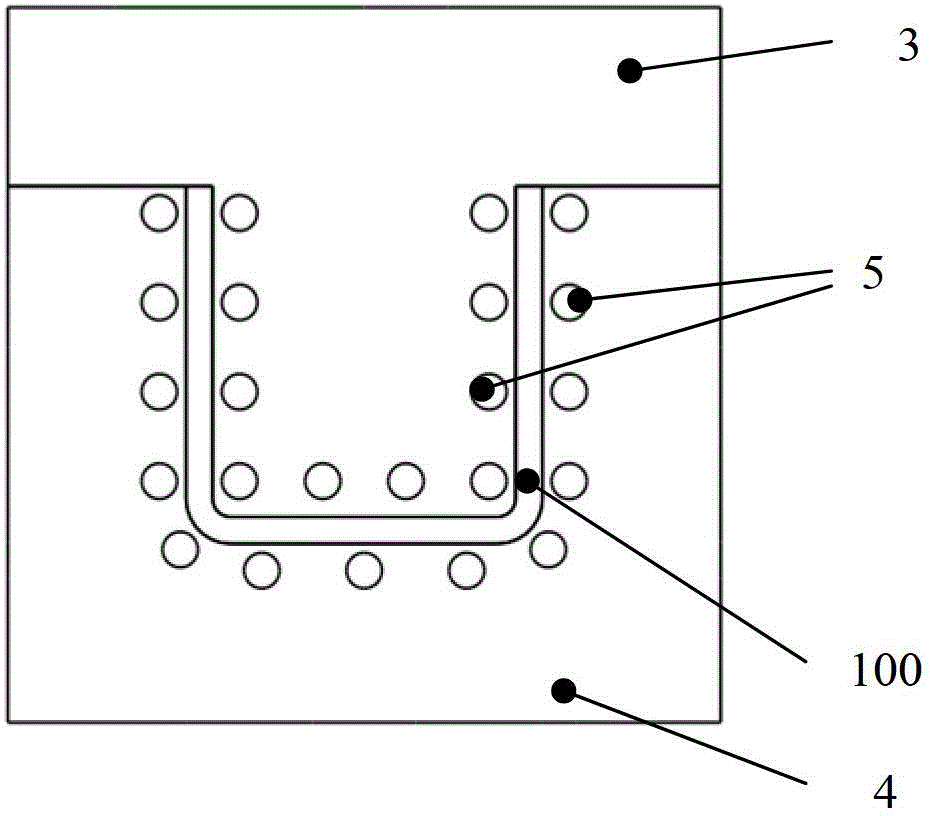

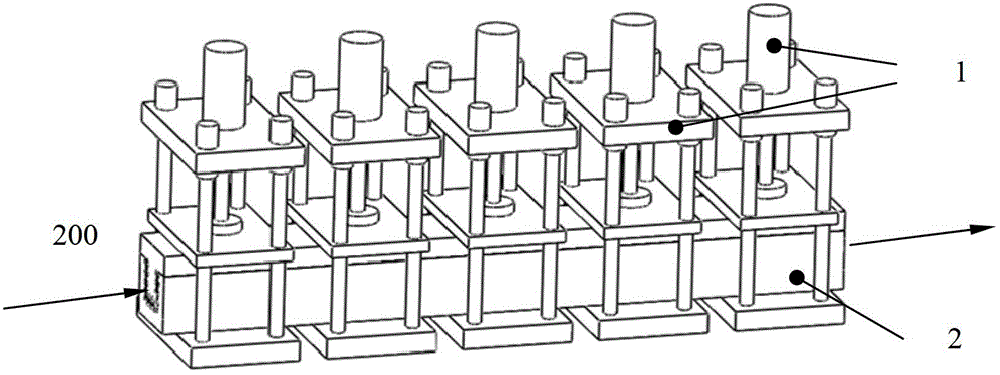

[0034] 1) Roll bending the room temperature boron steel sheet into a semi-finished product with open profile; 2) Heat the semi-finished product to 800°C and keep it warm for 2 minutes; 3) Quickly transfer the high-temperature semi-finished product to the shaping mold; 4) The upper and lower matching punches and concave molds will It is completely covered and loaded to shape it. At the same time, the circulating cooling medium is passed on the surface of the mold to cool down the profile at a speed of 30°C / s under pressure; the shaping and cooling are completed at the same time, and the normal temperature and Dimensional opening profiles.

Embodiment 2

[0036] 1) Roll bending the room temperature boron steel sheet into a semi-finished product with open profile; 2) Heat the semi-finished product to 1100°C and keep it warm for 4 minutes; 3) Quickly transfer the high-temperature semi-finished product to the shaping mold; 4) The punch\concave mold completely covers the profile And load it to shape it, and at the same time, circulate the cooling medium on the surface of the mold to cool down the profile at a speed of 50°C / s under pressure; the shape and cooling are completed at the same time, and the normal temperature and qualified size are obtained after the mold is opened. Open profile.

Embodiment 3

[0038] 1) Roll bending the room temperature boron steel sheet into a semi-finished product with open profile; 2) Heat the semi-finished product to 1000°C and keep it warm for 5 minutes; 3) Quickly transfer the high-temperature semi-finished product to the shaping mold; 4) The punch\concave mold completely covers the profile And load it to shape it. At the same time, circulate the cooling medium on the surface of the mold to cool down the profile at a speed of 40°C / s under pressure; the shaping and cooling end at the same time, and after the mold is opened, a normal temperature and qualified size is obtained. Open profile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com