Method for synthesizing monodisperse stable LDHs (layered double hydroxides) colloid nanocrystalline

A synthesis method, technology of nanocrystals, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

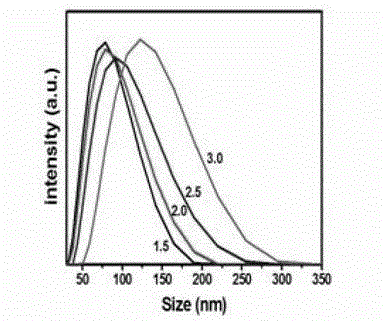

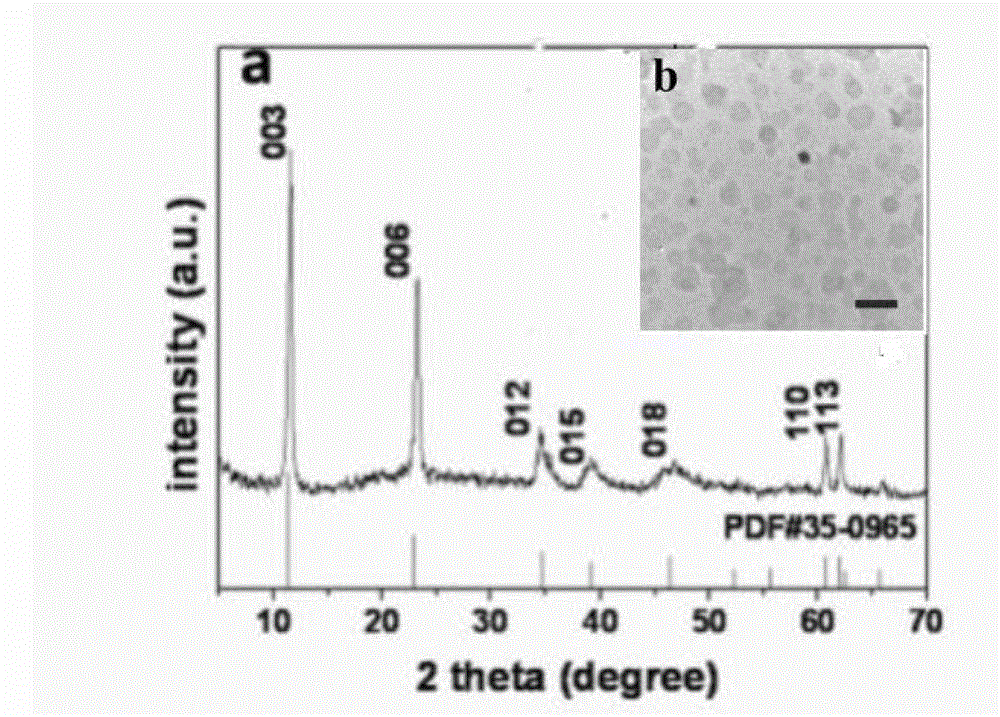

Embodiment 1

[0032] 1. Preparation of stable MgAl-LDH colloidal nanocrystal solution;

[0033] (1) Dissolve 10 mL containing 3 mmol MgCl 2 and 1 mmol AlCl 3 The mixed salt solution and 40 mL of 0.15 M NaOH solution were simultaneously poured into a high-speed rotating colloid mill for 10 min to obtain a white slurry;

[0034] (2) Centrifuge the white slurry at 12,000 rpm for 15 minutes and wash it with water three times;

[0035] (3) Add 40mL deionized water and stir until there are no large particles, then import it into a hydrothermal kettle and react in an oven at 100°C for 10 hours to obtain a stable transparent colloidal solution;

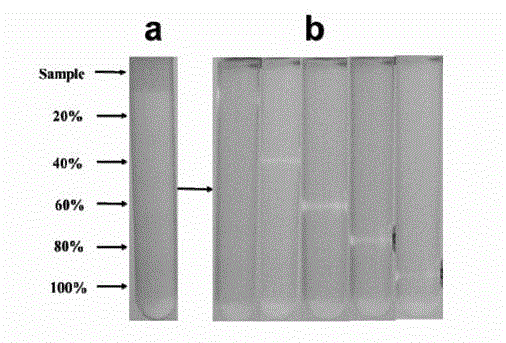

[0036] 2. Density gradient centrifugation:

[0037] (1) Make a density gradient: Use ethylene glycol and water to prepare 20%, 40%, 60%, 80%, and 100% ethylene glycol aqueous solutions by volume. Starting with ethylene glycol, slowly add 2 mL of the solution to the centrifuge tube in sequence to prepare a gradient solution.

[0038] (2) Add 1 mL of th...

Embodiment 2

[0044] 1. Preparation of stable MgAl-LDH colloidal nanocrystal solution;

[0045] (1) Dissolve 10 mL containing 3 mmol MgCl 2 and 1 mmol AlCl 3 The mixed salt solution and 40 mL of 0.15 M NaOH solution were simultaneously poured into a high-speed rotating colloid mill for 10 min to obtain a white slurry;

[0046] (2) Centrifuge the white slurry at 12,000 rpm for 15 min and wash it with water three times;

[0047] (3) Add 40 mL of deionized water and stir until there are no large particles, then import it into a hydrothermal kettle and react in an oven at 100 °C for 10 h to obtain a stable transparent colloidal solution;

[0048] 2. Density gradient centrifugation:

[0049] (1) Make a density gradient: Use ethylene glycol and water to prepare 20%, 40%, 60%, 80%, and 100% ethylene glycol aqueous solutions by volume. Starting with ethylene glycol, slowly add 0.8 mL of the solution to the centrifuge tube to prepare a gradient solution.

[0050] (2) Add 0.5 mL of the stable ...

Embodiment 3

[0054] 1. Preparation of stable MgAl-LDH colloidal nanocrystal solution;

[0055] (1) Dissolve 10 mL containing 3 mmol MgCl 2 and 1 mmol AlCl 3 The mixed salt solution and 40 mL of 0.15 M NaOH solution were simultaneously poured into a high-speed rotating colloid mill for 10 min to obtain a white slurry;

[0056] (2) Centrifuge the white slurry at 12,000 rpm for 15 min and wash it with water three times;

[0057] (3) Add 40 mL of deionized water and stir until there are no large particles, then introduce it into a hydrothermal kettle and react in an oven at 80 °C for 16 h to obtain a stable transparent colloidal solution;

[0058] 2. Density gradient centrifugation:

[0059] (1) Make a density gradient: Use ethylene glycol and water to prepare 20%, 40%, 60%, 80%, and 100% ethylene glycol aqueous solutions by volume. Starting with ethylene glycol, slowly add 2 mL of the solution to the centrifuge tube in sequence to prepare a gradient solution.

[0060] (2) Add 1 mL of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com