Two-step oxidation production method for iron oxide red pigment

A technology for iron oxide red and pigment, which is applied in the field of two-step oxidation to produce iron oxide red pigment, can solve the problems of high production cost of iron oxide red pigment, secondary environmental pollution and potential safety hazard, etc., and achieves easy availability of raw materials and uniform particle size. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

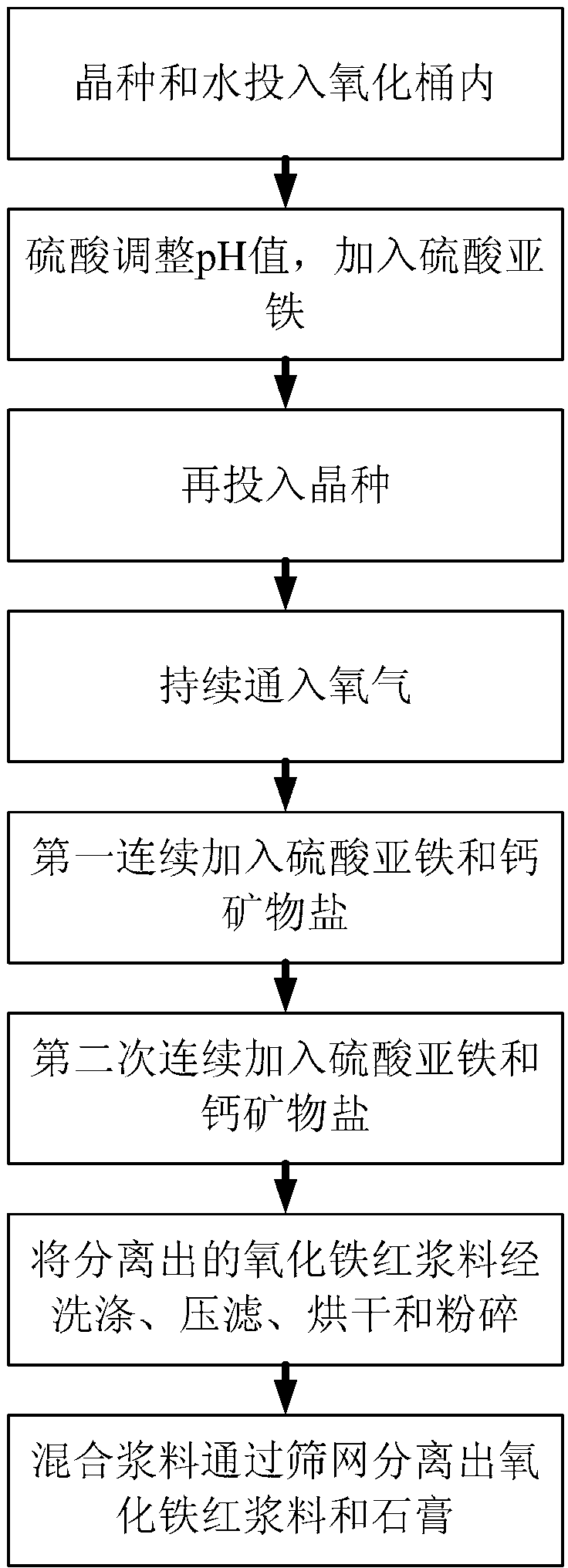

Image

Examples

Embodiment 1

[0031] The present embodiment prepares iron oxide red pigment by the following method:

[0032] A method for producing iron oxide red pigment by two-step oxidation, comprising the following steps:

[0033] Step 1, using α-FeOOH as the seed crystal, putting the seed crystal and water into the oxidation tank, the seed crystal input amount is 50% of the total amount of ferrous sulfate in the subsequent step 2.

[0034] Step 2: Use a small amount of sulfuric acid to adjust the pH value of the solution in the oxidation tank to 4, and raise the temperature to 70-73°C, add ferrous sulfate to the solution in the oxidation tank, so that the concentration of ferrous sulfate in the solution is 35g / L , then drop into seed crystal to the solution in the oxidation barrel, the seed crystal input amount is 10% of the consumption of the ferrous sulfate used in the step 2; The consumption of the ferrous sulfate in the step 2 is 600kg.

[0035] Step 3. Continuously feed oxygen into the solution...

Embodiment 2

[0040] A method for producing iron oxide red pigment by two-step oxidation, comprising the following steps:

[0041] Step 1, using α-FeOOH as the crystal seed, put the seed crystal and water into the oxidation barrel, the seed crystal input amount is 52% of the total amount of ferrous sulfate in the subsequent step 2, and the mass ratio of the seed crystal to water is 1 :7.

[0042] Step 2: Use a small amount of sulfuric acid to adjust the pH value of the solution in the oxidation tank to 4, and raise the temperature to 70-73°C, add ferrous sulfate to the solution in the oxidation tank, so that the concentration of ferrous sulfate in the solution is 38g / L , then drop into crystal seed to the solution in the oxidation barrel, the seed crystal input amount is 18% of the consumption of the ferrous sulfate used in the step 2; The consumption of the ferrous sulfate in the step 2 is 750kg.

[0043] Step 3. Continuously feed oxygen into the solution in the oxidation barrel obtained ...

Embodiment 3

[0048] A method for producing iron oxide red pigment by two-step oxidation, comprising the following steps:

[0049] Step 1, using α-FeOOH as the seed crystal, putting the seed crystal and water into the oxidation barrel, the seed crystal input amount is 55% of the total amount of ferrous sulfate in the subsequent step 2.

[0050] Step 2: Use a small amount of sulfuric acid to adjust the pH value of the solution in the oxidation tank to 4, and raise the temperature to 70-73°C, add ferrous sulfate to the solution in the oxidation tank, so that the concentration of ferrous sulfate in the solution is 34g / L , then drop into crystal seed to the solution in the oxidation barrel, the seed crystal input amount is 10~20% of the consumption of the ferrous sulfate used in the step 2; The consumption of the ferrous sulfate in the step 2 is 800kg.

[0051] Step 3: Continuously feed oxygen into the solution in the oxidation barrel obtained in step 2 for oxidation, keep the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com