Excitant for inferior lime-cement mixed material and preparation method thereof

A technology of limestone and activator, which is applied in the field of cement grinding aids, can solve the problems of unsatisfactory application of inactive and inferior limestone mixtures, insufficient guarantee of cement quality, and easy hydration reaction of active ingredients, etc., to achieve Improve the stability and setting time, shorten the initial setting and final setting time of cement, and facilitate the maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

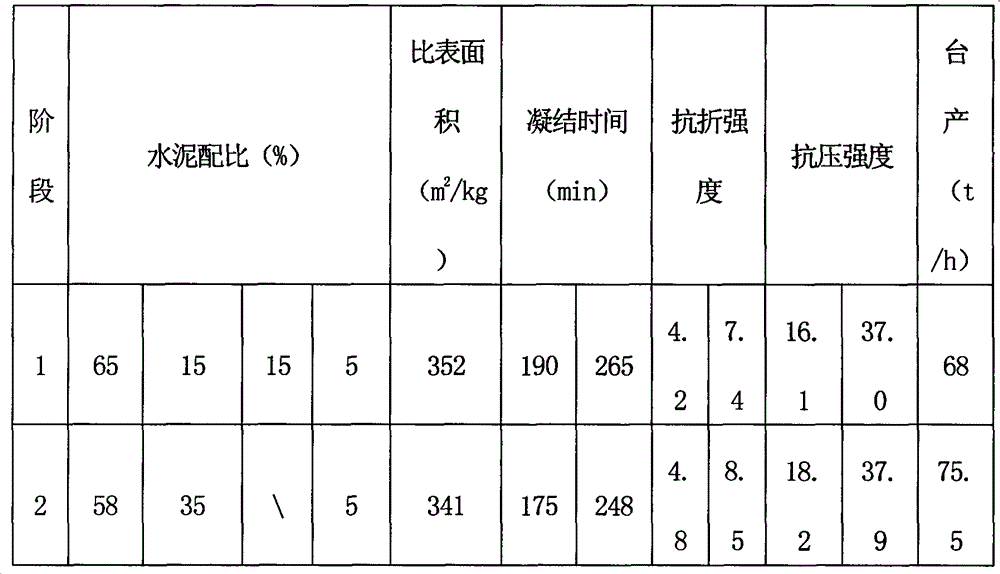

Examples

Embodiment Construction

[0028] Invention stimulator of the present invention adopts following formula (weight %):

[0029] components

Example 1

Example 2

Example 2

30

35

25

calcium lignosulfonate

3

1

5

3

4

2

sugar calcium

12

8

10

Sodium Alkylbenzene Polymerase Sulfonate

6

4

8

2

6

4

water

44

42

46

total

100%

100%

100%

[0030] The sugar calcium in the formula is obtained by modifying the white waste sugar liquid produced in the white sugar production process with corn as the main raw material through lime water.

[0031] Preparation of Invention Stimulator:

[0032] Step 1. Diethanolamine, calcium lignosulfonate, calcium sugar, and barium sulfate in the above formula were diluted with water and stirred for 40 minutes;

[0033] Step 2. Add alkylbenzene polyase sodium sulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com