LSZH Flame Retardant Sheath for Optical Cables

A flame retardant sheath and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as adhesion, increase scratch resistance and wear resistance, reduce torque, and improve surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

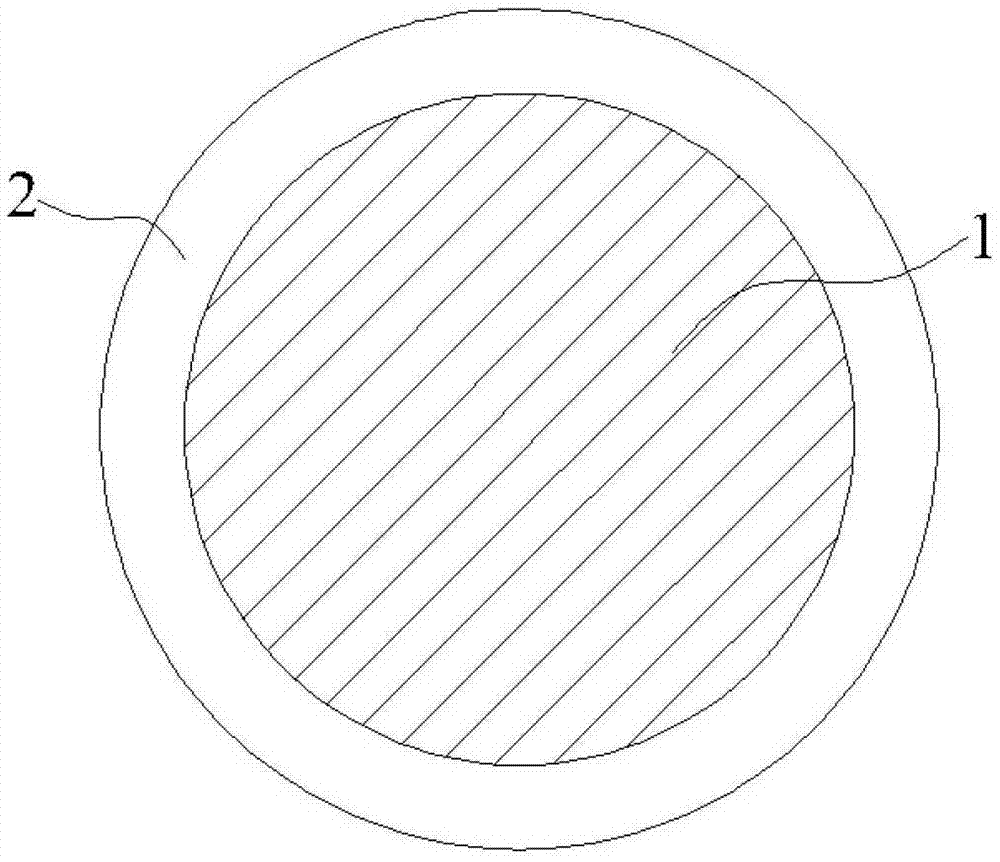

[0029] Embodiment 1: A low-smoke, halogen-free, flame-retardant sheath layer for an optical cable, the optical cable includes an optical cable core 1 and a low-smoke, halogen-free, flame-retardant sheath layer 2 coated on the outer surface of the optical cable core 1, the The low-smoke halogen-free flame-retardant sheath layer 2 is obtained by processing the following components by weight:

[0030] 69 parts of ethylene-vinyl acetate copolymer,

[0031] 21 parts of high-pressure metallocene polyethylene,

[0032] 10 parts of modified polyethylene,

[0033] 105 parts of aluminum hydroxide,

[0034] 10 parts of magnesium hydroxide,

[0035] 4.5 parts of silicone masterbatch,

[0036] Polyethylene wax 1.8 parts,

[0037] flow agent 20 copies,

[0038] 0.45 part of antioxidant,

[0039] 3 parts of black masterbatch;

[0040] The above flow agent is produced by Haimen Xinlongxiang Special Plastic Co., Ltd.

[0041] The VA content of the ethylene-vinyl acetate copolymer (E...

Embodiment 2

[0047] Embodiment 2: A low-smoke, halogen-free, flame-retardant sheath layer for an optical cable, the optical cable includes an optical cable core 1 and a low-smoke, halogen-free, flame-retardant sheath layer 2 coated on the outer surface of the optical cable core 1, the The low-smoke halogen-free flame-retardant sheath layer 2 is obtained by processing the following components by weight:

[0048] 69 parts of ethylene-vinyl acetate copolymer,

[0049] 21 parts of high-pressure metallocene polyethylene,

[0050] 15 parts of modified polyethylene,

[0051] 75 parts of aluminum hydroxide,

[0052] 30 parts of magnesium hydroxide,

[0053] 4.5 parts of silicone masterbatch,

[0054] Polyethylene wax 1.8 parts,

[0055] 30 parts of flowable agent,

[0056] 0.45 part of antioxidant,

[0057] 4 parts black masterbatch;

[0058] The VA content of the ethylene-vinyl acetate copolymer (EVA) is 20-28%;

[0059]The high-pressure metallocene polyethylene (EPPE) has a melting inde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com