Silicon solar cell surface light trapping structure and preparation method thereof

A technology of silicon solar cells and solar cells, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of high cost, high equipment requirements, and difficulty in obtaining production processes for tank-type equipment, and achieve corrosion-free Sexuality, the effect of reducing the degree of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

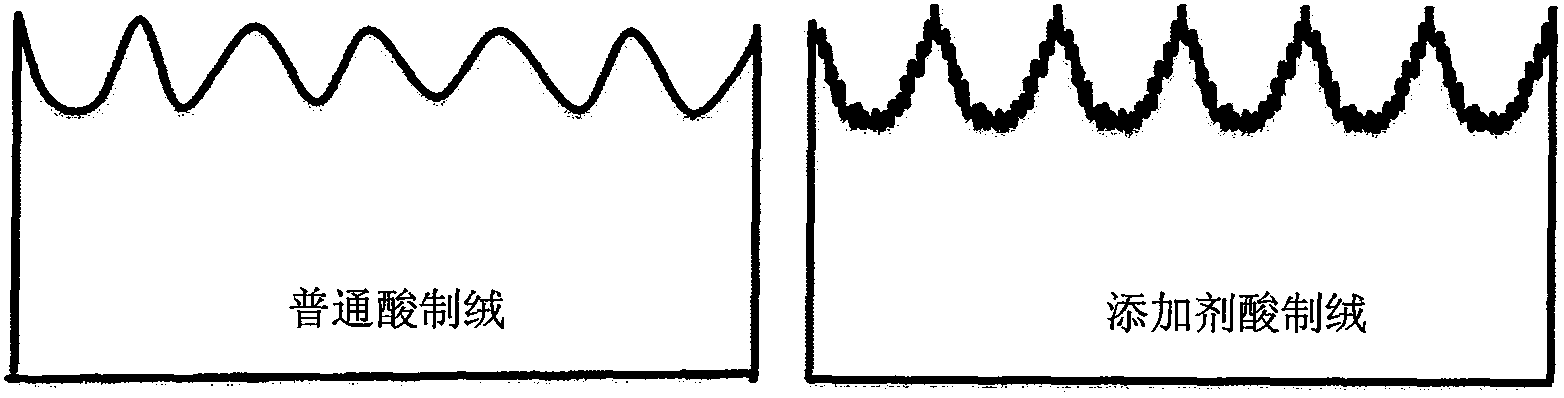

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific implementation steps are as follows: 1) preparation of additives: 100 ml of deionized water is used as solvent, 1 ml of glycerin, 1 gram of citric acid, and 1 ml of crown ether type surfactant are dissolved in deionized water to prepare additives; 2) preparation of acid corrosion solution: HF, HNO 3 , H 2 O is mixed in a volume ratio of 1:5:4; 3) Prepare alkali rinse solution: dissolve solid NaOH in deionized water at a ratio of 5% by weight; 4) Add additives at 0.1% to 2) Prepared acid corrosion 5) immerse the monocrystalline or polycrystalline silicon sheet for solar cells in the texturing solution for reaction, and the reaction temperature is 12 ℃ , the texturing time is 200s; 6) Take out the silicon wafer treated in 5), rinse it with water for 2 minutes, then immerse it in the alkali solution prepared in step 3) to react for 45 seconds, take it out, rinse it, and dry it.

Embodiment 2

[0034] The specific implementation steps are as follows: 1) preparation of additives: 100 ml of deionized water is used as a solvent, 3 ml of glycerin, 0.6 gram of citric acid, and 0.5 ml of crown ether type surfactants are dissolved in deionized water to prepare additives; 2) preparation of acid corrosion solution : HF, HNO 3 , H 2 O is mixed at a volume ratio of 1:8:5; 3) Prepare alkali rinse solution: dissolve solid NaOH in deionized water at a ratio of 5% by weight; 4) Add additives at 0.5% to 2) Prepared acid corrosion Form the texturing solution in the liquid; 5) Immerse the monocrystalline or polycrystalline silicon wafer for solar cells in the texturing solution for reaction, and the reaction temperature is 15 ℃ , the texturing time is 180s; 6) Take out the silicon wafer treated in 5), rinse it with water for 2 minutes, then immerse it in the alkali solution prepared in step 3) to react for 45 seconds, take it out, rinse it, and blow dry.

Embodiment 3

[0036] The specific implementation steps are as follows: 1) preparation of additives: 100 ml of deionized water is used as a solvent, 10 ml of glycerin, 1 gram of citric acid, and 0.1 ml of crown ether type surfactants are dissolved in deionized water to prepare additives; 2) preparation of acid corrosion solution : HF, HNO 3 , H 2 O is mixed at a volume ratio of 1:4:3; 3) Prepare alkali rinse solution: dissolve solid NaOH in deionized water at a ratio of 5% by weight; 4) Add additives at 1% 2) Prepared acid corrosion Form the texturing solution in the liquid; 5) Immerse the monocrystalline or polycrystalline silicon wafer for solar cells in the texturing solution for reaction, and the reaction temperature is 18 ℃ , the texturing time is 240s; 6) Take out the silicon wafer treated in 5), rinse it with water for 2 minutes, then immerse it in the alkali solution prepared in step 3) to react for 45 seconds, take it out, rinse it, and dry it.

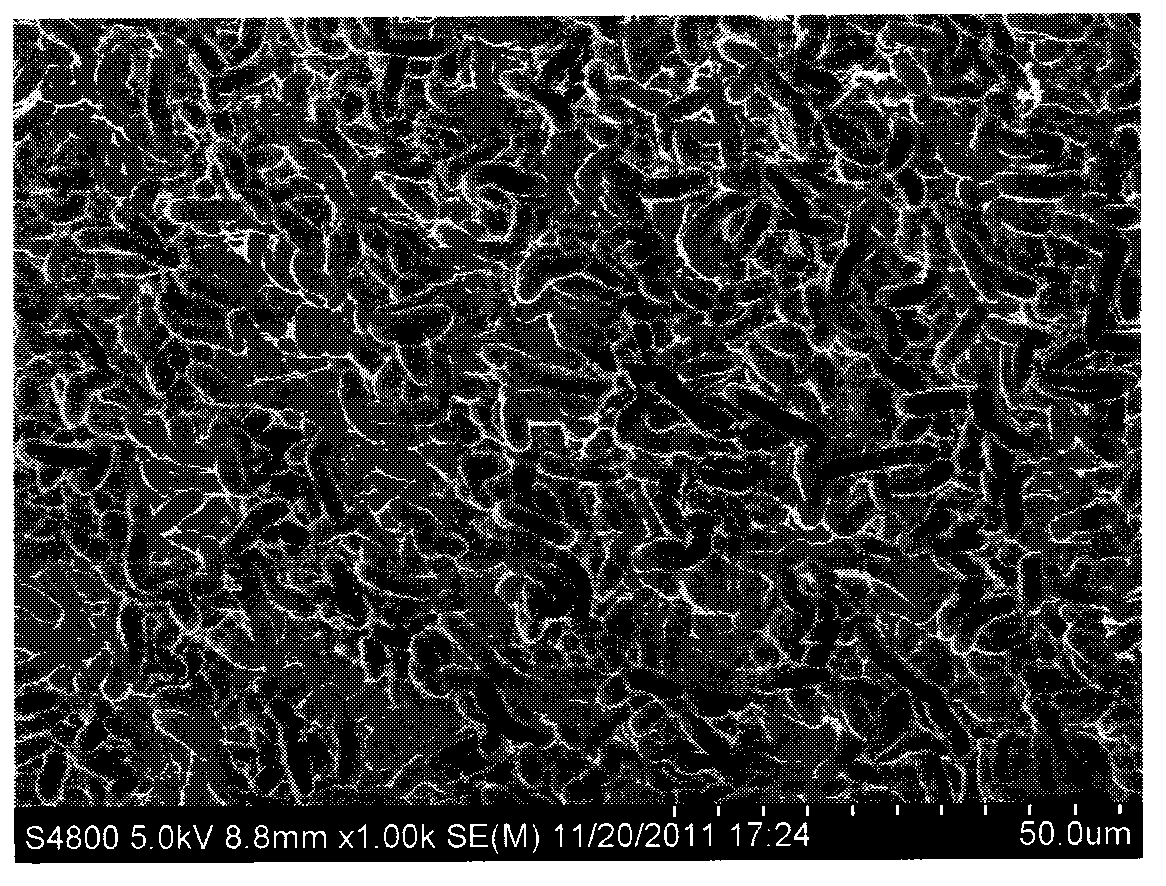

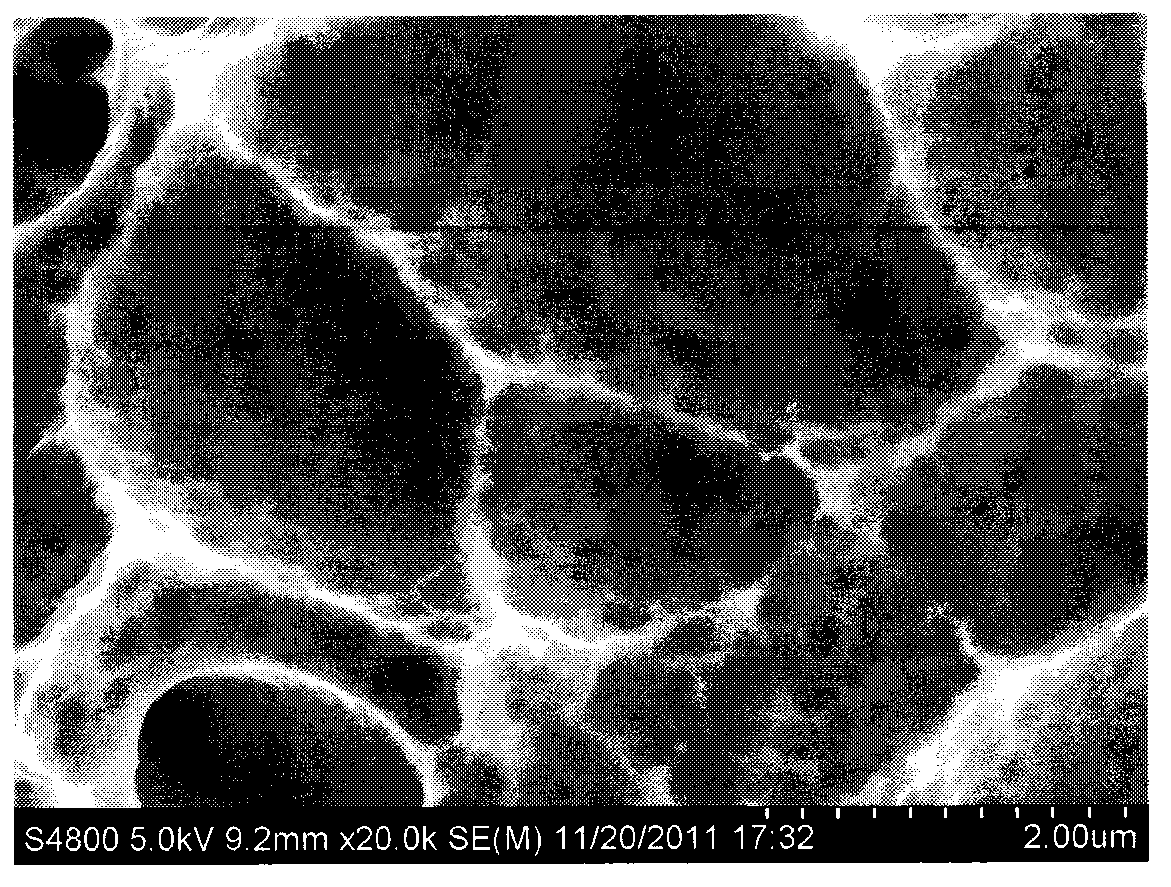

[0037] figure 2A scanning electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com