Plugging and leakage-proof construction method of kitchen and toilet flue and water supply and drainage pipeline edge

A construction method, water supply and drainage technology, applied in the treatment of pipes, building materials, pipes/pipe joints/fittings, etc., can solve the problems of improper quality awareness, difficulty in handling, inconvenience for owners, etc., to achieve fast construction progress and reduce construction costs. cost and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

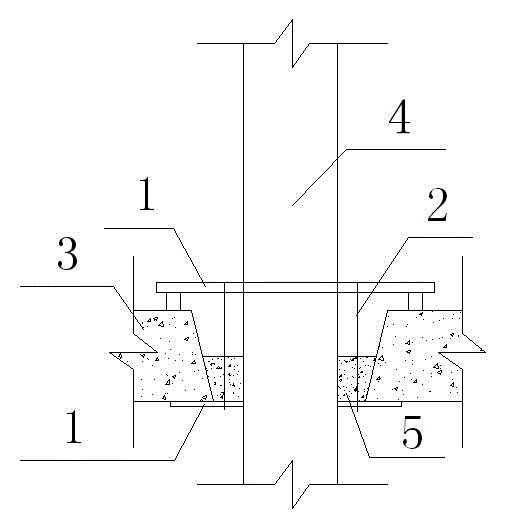

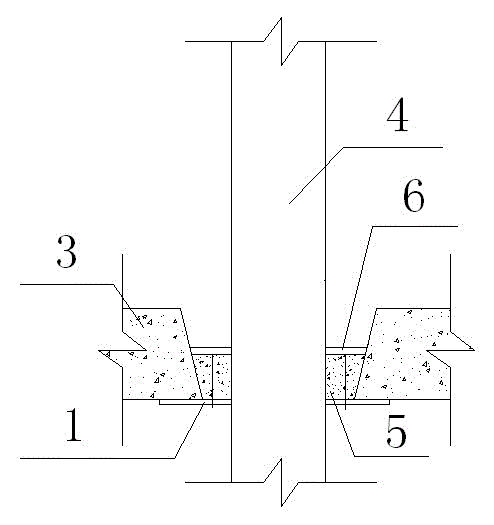

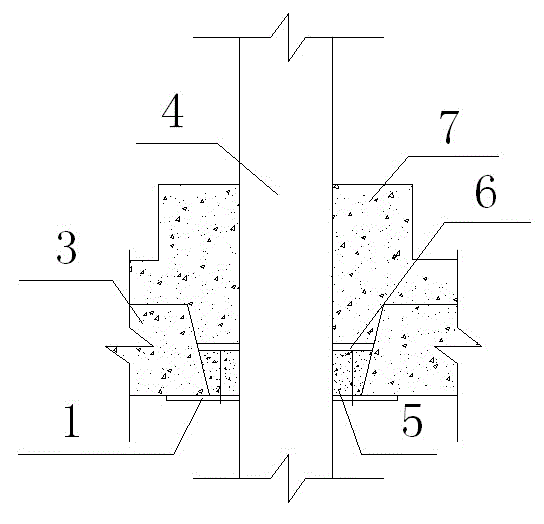

[0035] In the high-rise residential project under construction of Nanjing Branch, the construction method of the kitchen and bathroom flue, water supply and drainage pipes adopts this sealing and leak-proof construction method, such as figure 1 As shown, do a good job of treating the base layer around the reserved holes of the water supply and drainage pipe 4, chisel the reserved holes into a "funnel" shape with a thick top and a thin bottom, and there is a distance of 30-50mm between the lower opening of the reserved hole and the installation of the water supply and drainage pipe 4 The gaps, and remove the loose concrete, brush it with a wire brush and then rinse it with clean water; use (model Q9) dry sandpaper to clean the water supply and drainage pipes 4's The outer wall is roughened to better combine with the plugging concrete, and the grinding position is at the contact point between the newly poured plugging concrete and the water supply and drainage pipe 4, while in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com