Fuel gas treatment device

A fuel gas and processing device technology, which is applied in the directions of fuel injection control, electrical control, engine components, etc., can solve the problems that fuel gas is difficult to dissolve into engine oil, the system is complicated, and the number of parts is increased, so as to reduce the number of parts and reduce the number of parts. Design changes, the effect of efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

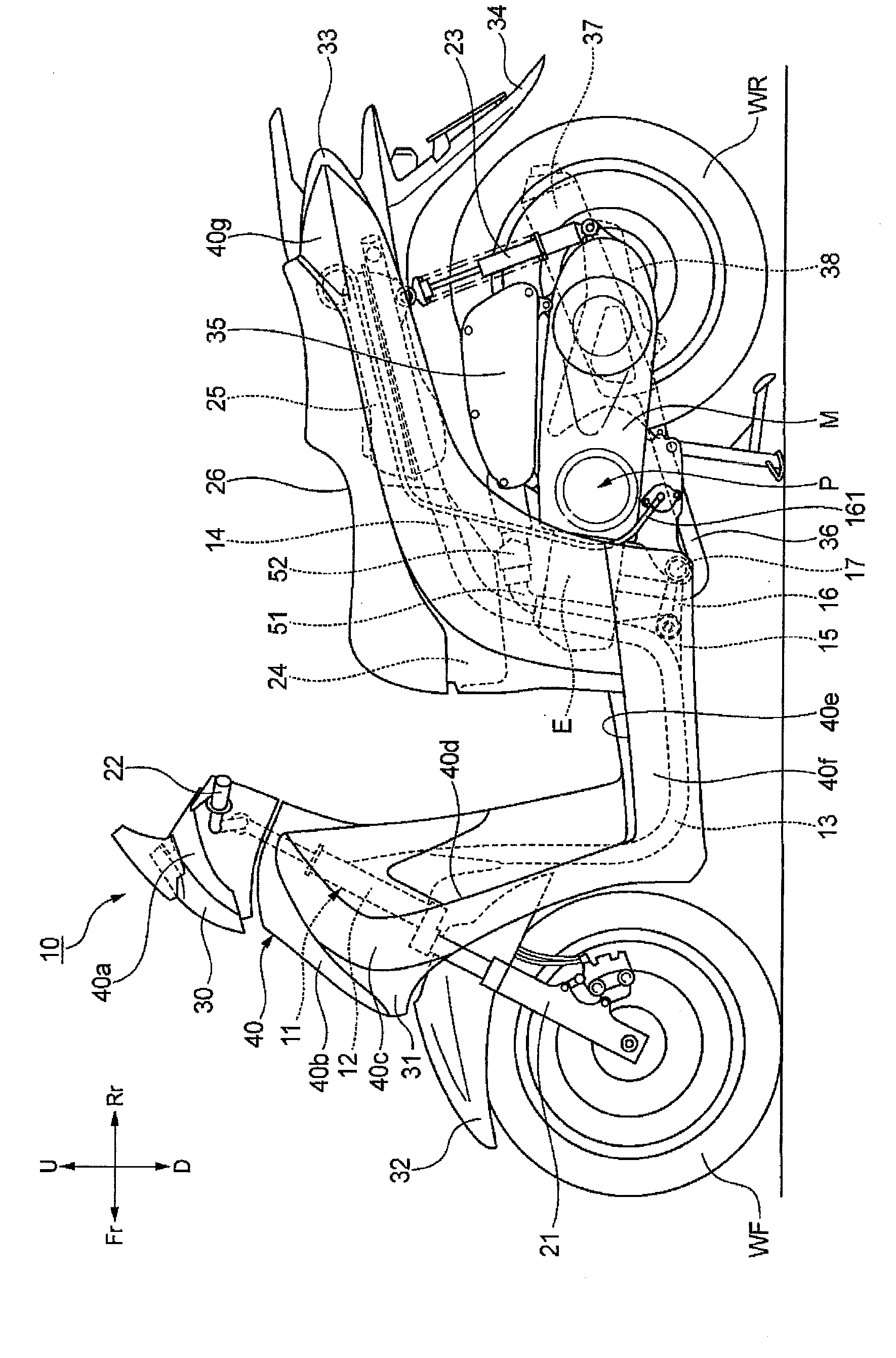

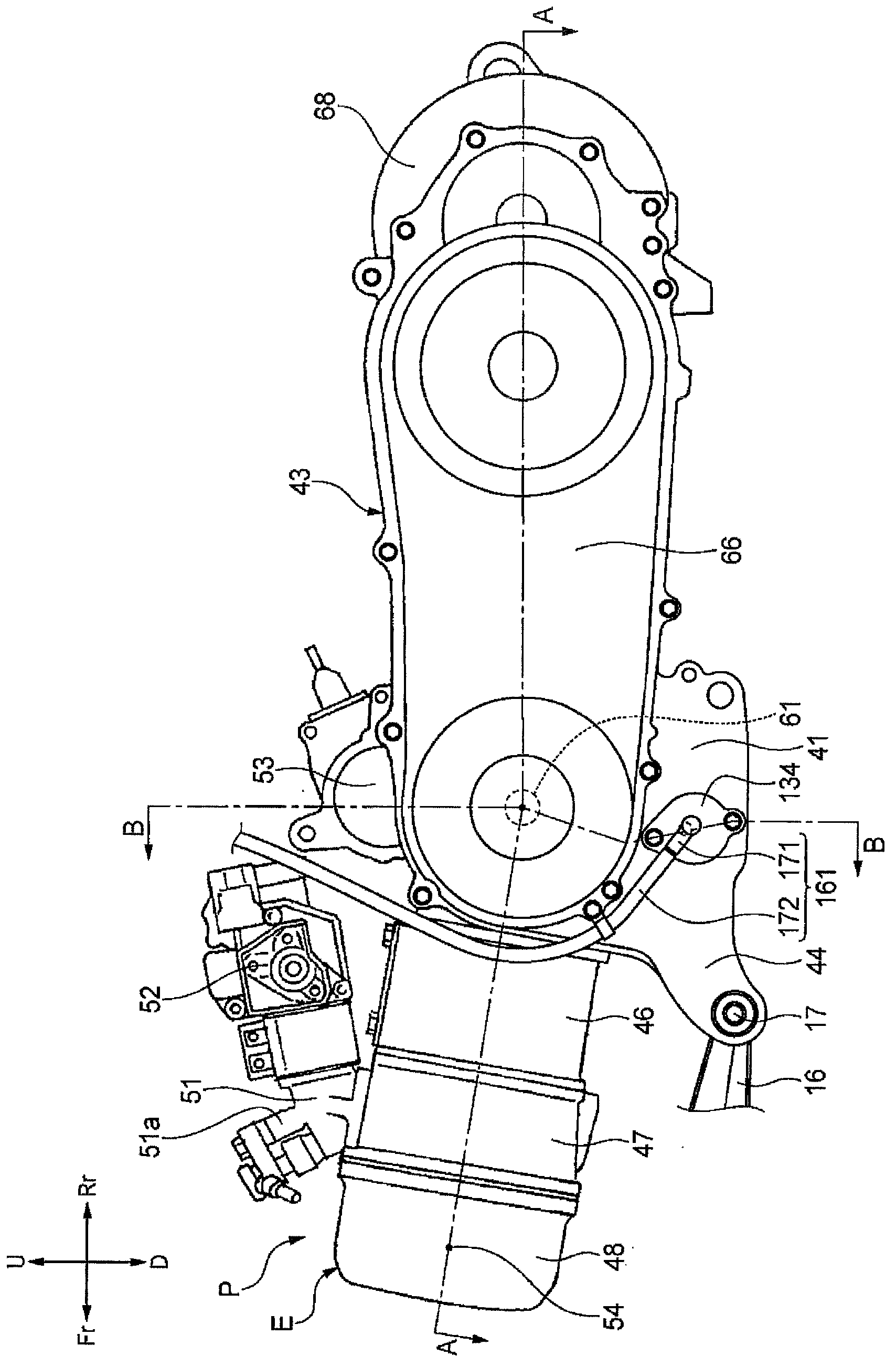

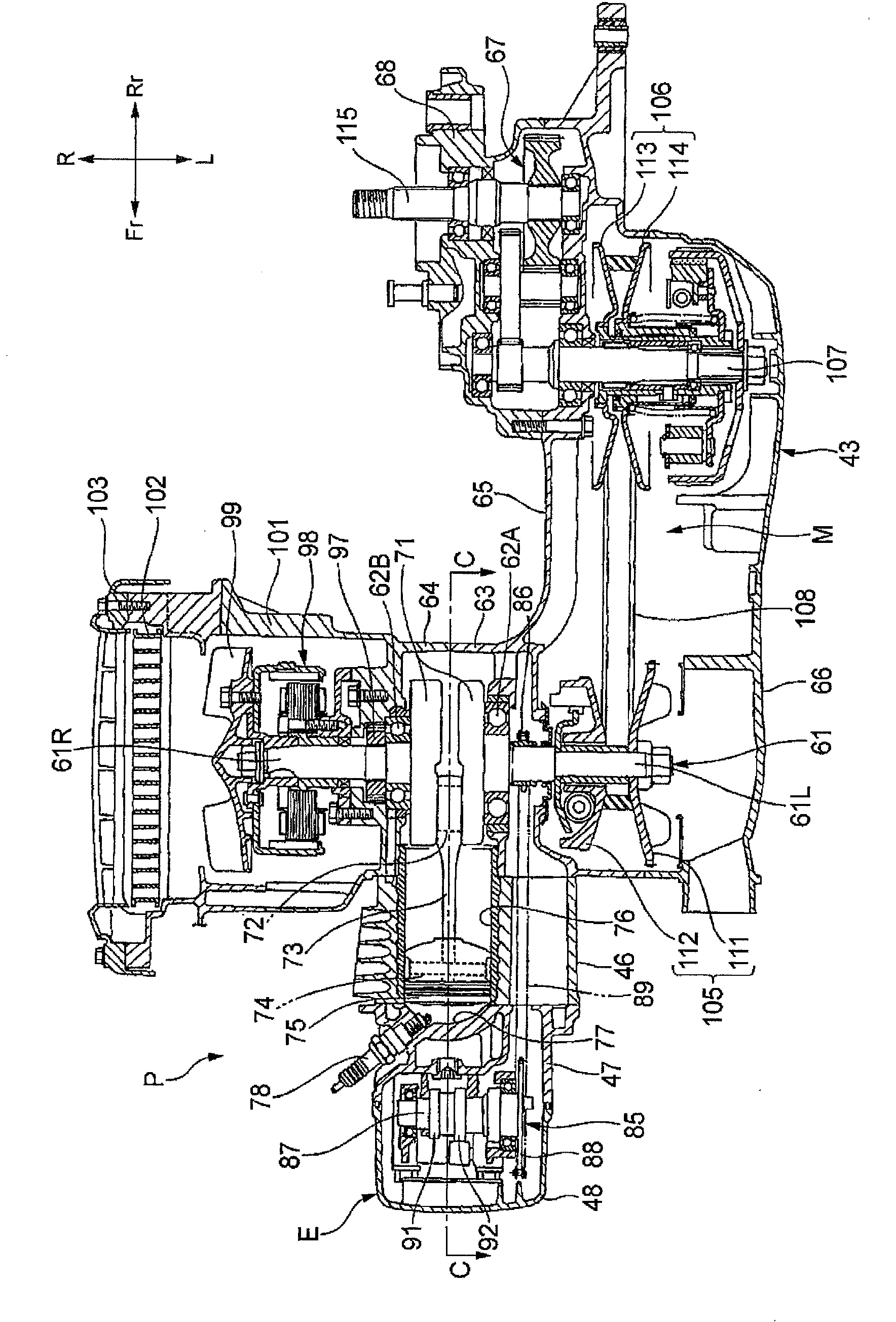

[0049] Hereinafter, an embodiment of the fuel gas processing device of the present invention will be described in detail with reference to the drawings. In addition, the drawings are viewed in the direction of the symbols. In the following description, front and rear, left and right, and up and down are in accordance with the directions seen from the operator. In the drawings, the front of the vehicle is represented by Fr, the rear by Rr, and the left side It is represented by L, the right side is represented by R, the top is represented by U, and the bottom is represented by D.

[0050] The two-wheeled motor vehicle 10 of the present embodiment is a scooter type vehicle, such as figure 1 As shown, the vehicle frame 11 is composed of the following parts: a head pipe 12, which is arranged at the front end; a main frame 13, which extends downward from the head pipe 12 and extends backward; a pair of left and right rear frames 14, which extend from the rear of the main frame 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com