Bi-energy pneumatic submersible pump for mine

A submersible pump and dual-power technology, which is applied in the field of dual-power mine pneumatic submersible pumps, can solve the problems of complex operating conditions, no flow regulating valve in the water discharge pipeline, and the lift cannot meet the user's requirements, etc., to achieve good adaptability, The effect of reliable assembly connection and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

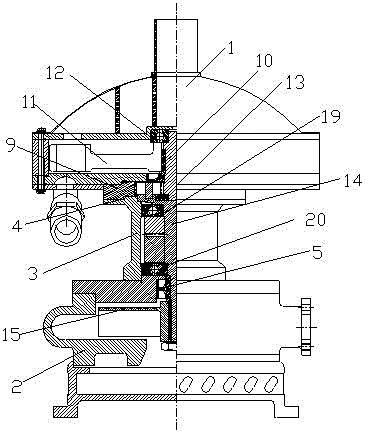

[0037] Preferred embodiment one of the present invention: the motor 1 is a turbine air motor, and the turbine air motor includes a turbine output shaft 10, a turbine 11 arranged on the turbine output shaft 10, and the turbine output shaft 10 is respectively provided with Bearing 12 on the turbine output shaft and bearing 13 under the turbine output shaft are arranged.

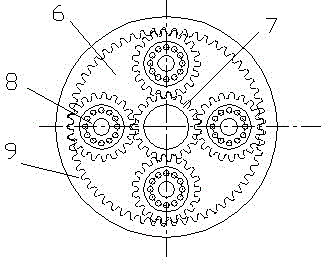

[0038] The sun gear 7 is integrally arranged on one end of the turbine output shaft 10, the water pump 2 includes a power shaft 14, the power shaft 14 is integrally arranged with the planet carrier 6, and the output end of the power shaft 14 is provided with impeller blades 15.

[0039] The turbine output shaft 10 is the input shaft of the variable speed transmission device 3, and the output shaft of the variable speed transmission device 3 is the power shaft 14 of the water pump 2. There is no coupling in the middle between the turbine output shaft 10 and the power shaft 14. The transitional flange has no asy...

Embodiment 2

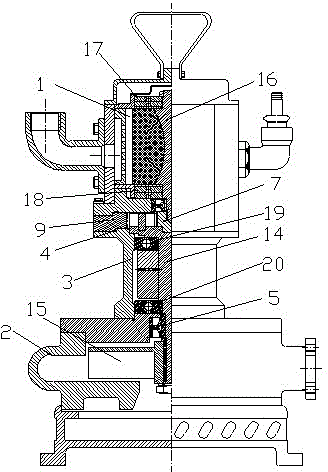

[0042] Preferred embodiment 2 of the present invention: the motor 1 is a volume vane air motor, and the volume vane air motor includes a vane rotor shaft 16, and the vane rotor shaft 16 is provided with an upper rotor shaft bearing 17 and a rotor shaft lower bearing. bearing 18.

[0043] The output end of the vane rotor shaft 16 is connected to the sun gear 7, the water pump 2 includes a power shaft 14, and the power shaft 14 is integrated with the planet carrier 6, and the output end of the power shaft 14 is provided with an impeller slice 15.

[0044] The blade type rotor shaft 16 is the input shaft of the variable speed transmission device 3, the output shaft of the variable speed transmission device 3 is the power shaft 14 of the water pump 2, there is no coupling between the blade type rotor shaft 16 and the power shaft 14, No transitional flange, no asymmetry, compact structure, simple transmission, and reasonable layout; if other reduction gear structures are used, the...

Embodiment 3

[0047] Preferred Embodiment 3 of the present invention: the motor 1 is a volumetric geared air motor, the volumetric geared air motor includes a geared rotor shaft, and the geared rotor shaft is provided with a rotor shaft upper bearing 17 and a rotor shaft lower bearing 18 .

[0048] The output end of the geared rotor shaft is connected to the sun gear 7, the water pump 2 includes a power shaft 14, and the power shaft 14 is integrated with the planet carrier 6, and the output end of the power shaft 14 is provided with impeller blades 15.

[0049] The geared rotor shaft is the input shaft of the variable speed transmission device 3, and the output shaft of the variable speed transmission device 3 is the power shaft 14 of the water pump 2. There is no coupling and no transition between the geared rotor shaft and the power shaft 14 Non-symmetrical flange, no asymmetry, compact structure, simple transmission, and reasonable layout; if other reduction gear structures are used, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com