Drilling and milling cutter

A technology for drilling and milling cutters and blades, which is applied in the direction of milling cutters, drill repairing, milling machine equipment, etc., can solve the problems of low processing efficiency and time-consuming, and achieve the effects of improving production efficiency, saving man-hours, and reducing cutting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

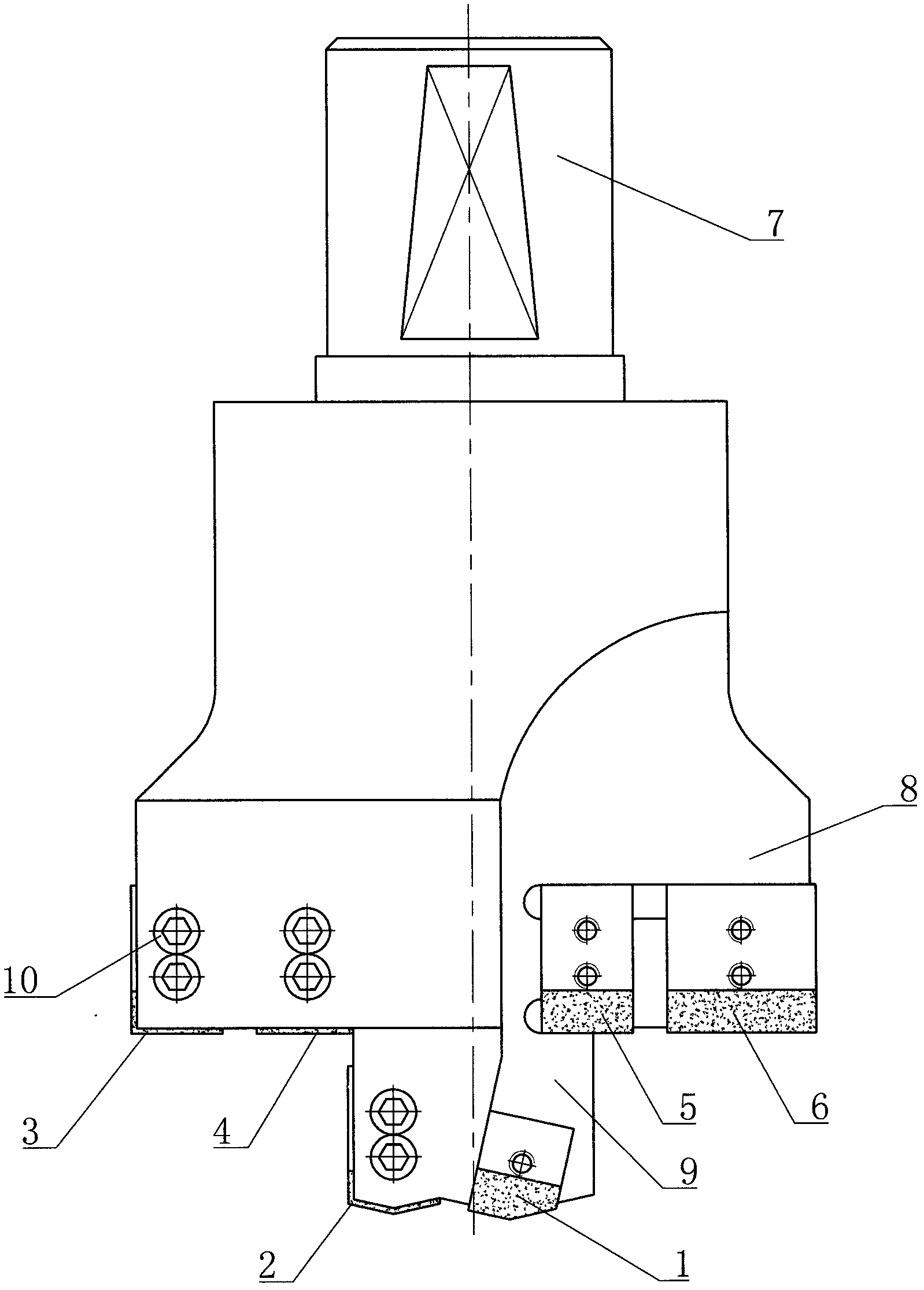

[0007] figure 1 Shown in is a specific embodiment of the present invention, and a kind of drilling and milling cutter of the present invention comprises blade I, blade II, blade III, blade IV, blade V, blade VI, cutter bar 7 and eleven socket head cap screws 10 , there is a large boss 8 on the cutter bar 7, and there is a small boss 9 below the big boss 8. The blade I and the blade II are installed on the small boss 9 through the inner hexagonal screws 10 at 180 degrees to each other. III, blade IV, blade V, and blade VI are installed on the large boss 8 at 180 degrees to each other through hexagon socket head screws 10, blade III and blade IV are installed in the same direction, and blade V and blade VI are installed in the same direction. Insert I, Insert II, Insert III, Insert IV, Insert V and Insert VI are carbide inserts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com