Method for manufacturing rim of inner tire-free wheel

A manufacturing method and rim technology, which can be used in manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of rim welding dislocation and reduce grinding workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

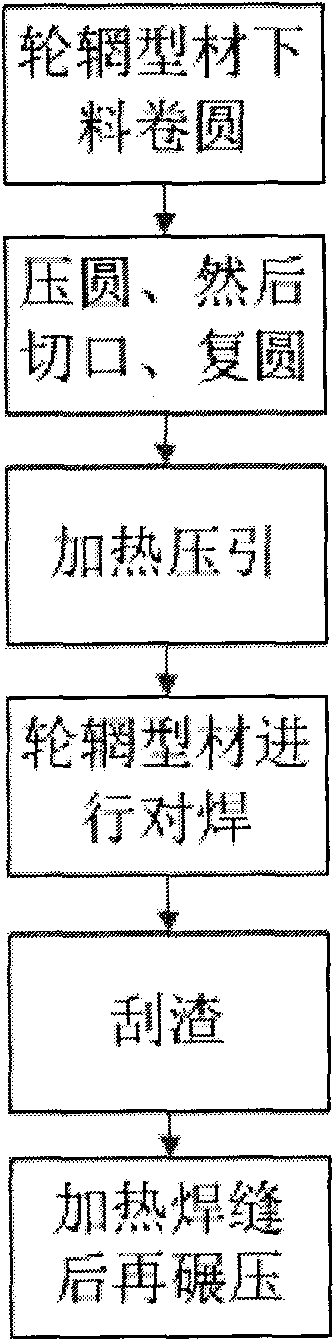

[0016] Below in conjunction with accompanying drawing, this patent is described in further detail.

[0017] Such as figure 1 Shown, the manufacturing method of tubeless wheel rim of the present invention comprises the steps:

[0018] (1) Cut the prefabricated rim profile according to the diameter of the rim and roll it into a circle;

[0019] (2) The rounded rim profiles are rounded in turn, then cut and rounded;

[0020] (3) Heating both ends of the rounded wheel rim profile obtained in step (2) at 350°C-450°C and then pressing it to form a uniform arc of the welding part of the rim;

[0021] (4) butt-weld the rim profiles obtained in step (3) with the same curvature of the welding part to obtain the rim blank;

[0022] (5), scraping slag on the rim preliminary blank after butt welding obtained in step (4);

[0023] (6) Carry out rolling after heating the weld seam after scraping the slag, the heating temperature is 350°C-450°C.

[0024] In practical application, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com