Method for preparing large-pore mesoporous molecular sieve

A technology of mesoporous molecular sieves and large pore diameters, applied in the direction of crystalline aluminosilicate zeolites, etc., can solve the problems of increased pore wall thickness, low reactivity, low hydrothermal stability, etc., achieve improved utilization rate, and simple synthesis method , Highly repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

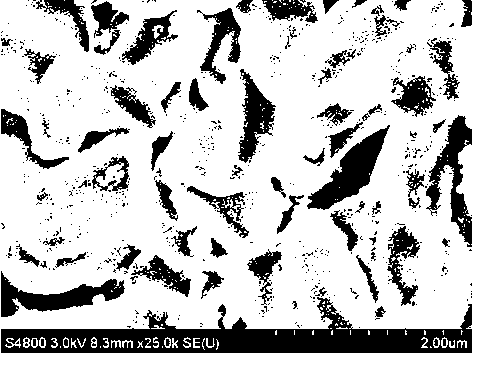

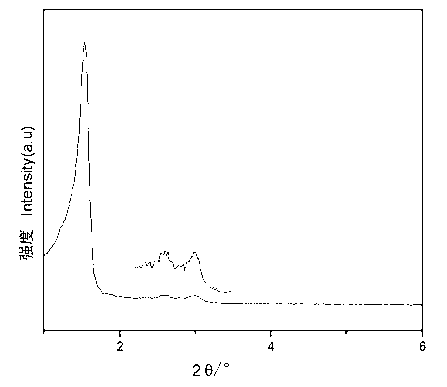

[0019] Synthesis of MCM-41 mesoporous material: The pure silicon macroporous MCM-41 mesoporous material was synthesized by the method reported in the literature, which was used as the starting material for the synthesis of macroporous MCM-41 mesoporous material. Take 50 ml of tetramethylammonium bromide solution with a molar concentration of 0.05 M, add 1.50 g of pure silicon MCM-41 mesoporous material containing surfactant, stir for 30 minutes, then transfer the mixture into a stainless steel reaction kettle, 150 °C After 2 days of crystallization, a macroporous MCM-41 mesoporous molecular sieve was obtained. The X-ray diffraction (XRD) and scanning electron microscope (SEM) characterization of the sample is as follows: figure 1 and figure 2 shown.

Embodiment 2

[0021] Synthesis of MCM-48 mesoporous material: The method reported in the literature was used to synthesize pure silicon MCM-48 mesoporous material as the starting material for the synthesis of macroporous MCM-48 mesoporous material. Take 50 ml of tetramethylammonium bromide solution with a molar concentration of 0.05 M, add 1.50 g of pure silicon MCM-48 mesoporous material containing surfactant, mix well, continue to stir for 30 minutes, and then transfer the mixture into a stainless steel reaction kettle Crystallization at 160°C for 2 days to obtain macroporous MCM-48 mesoporous molecular sieves.

Embodiment 3

[0023] Synthesis of SBA-15 mesoporous material: The pure silicon SBA-15 mesoporous material was synthesized by the method reported in the literature, and the block copolymer was removed by calcination at 550°C as the initial material for the synthesis of Al-SBA-15 mesoporous material. Take 50 ml of tetramethylammonium bromide solution with a molar concentration of 0.05 M, add 1.0 g of pure silicon SBA-15 mesoporous material roasted at high temperature, mix well, continue stirring for 30 minutes, and then transfer the mixture into a stainless steel reaction kettle, Crystallize at 170°C for 1 day to obtain a macroporous SBA-15 mesoporous molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com