Magnesite modifying agent

A magnesite modifier and the technology of the modifier, applied in the field of magnesite cementitious materials, can solve the problem that the effect of the modifier is not particularly ideal, and achieve the effects of improving product strength and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

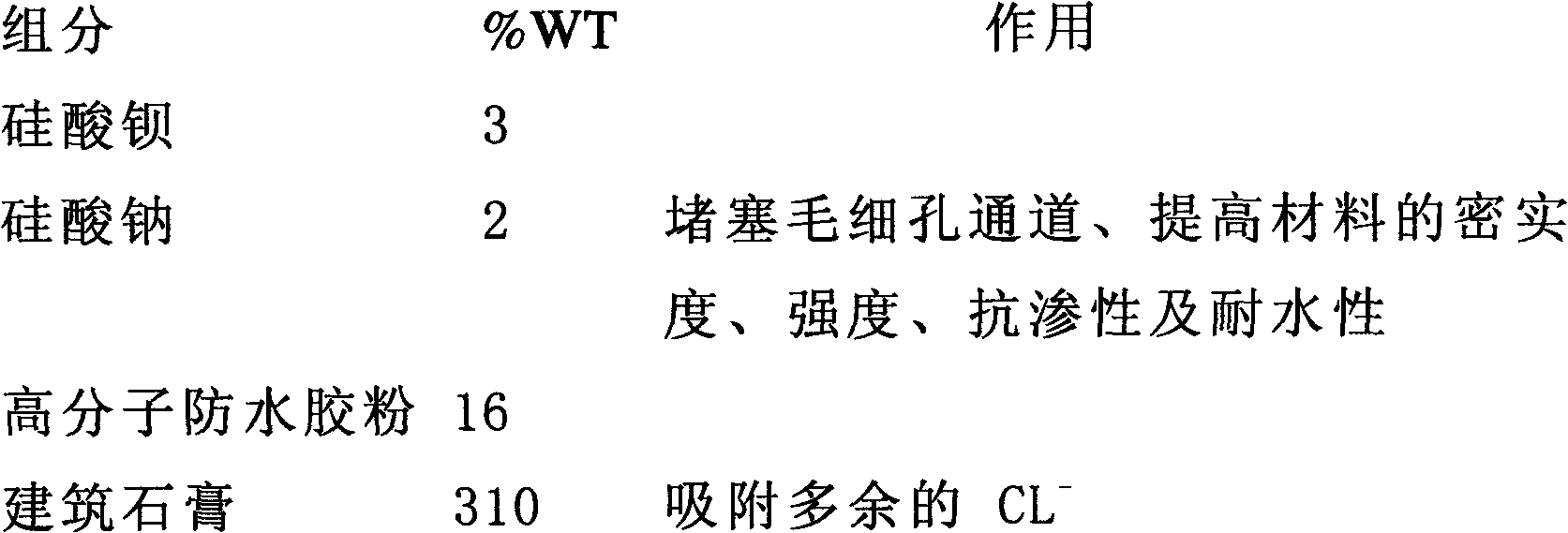

[0022] In the present embodiment, this magnesite modifier is made up of following composition:

[0023]

[0024]

[0025] The above ingredients are weighed and then stirred and mixed to make a powder.

[0026] Add the prepared improver to magnesite cement. After the magnesite cement is solidified, a hydrophobic film will be formed on the inner surface of the product, the capillary pores inside and the inner wall of the cavity, preventing the intrusion of water and reducing the impact of water on the product. erosion. At the same time, the magnesite modifier contains a considerable amount of surface active ingredients, which can fully contact and react magnesium oxide and magnesium chloride in a short period of time. The excess magnesium chloride is shielded, making it lose the opportunity to absorb moisture in the air medium, making up for the large Under the production volume, the mixing time of the slurry is short, which easily leads to the defect of insufficient mate...

Embodiment 2

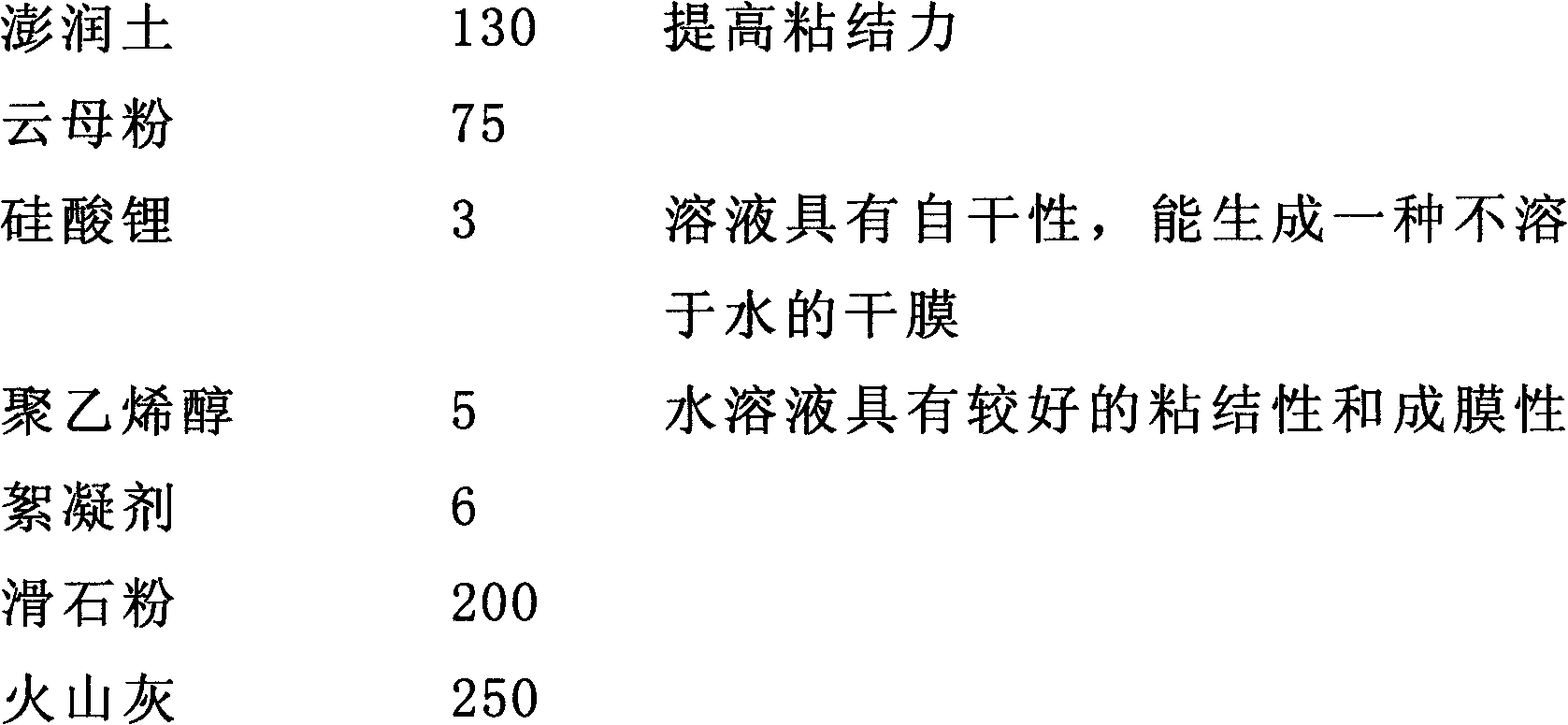

[0028] In the present embodiment, this magnesite modifier is made up of following composition:

[0029]

[0030]

[0031] The above ingredients are weighed and then stirred and mixed to make a powder.

[0032] Add the prepared improver to magnesite cement. After the magnesite cement is solidified, a hydrophobic film will be formed on the inner surface of the product, the capillary pores inside and the inner wall of the cavity, preventing the intrusion of water and reducing the impact of water on the product. erosion. At the same time, the magnesite modifier contains a considerable amount of surface active ingredients, which can fully contact and react magnesium oxide and magnesium chloride in a short period of time. The excess magnesium chloride is shielded, making it lose the opportunity to absorb moisture in the air medium, making up for the large Under the production volume, the mixing time of the slurry is short, which easily leads to the defect of insufficient mate...

Embodiment 3

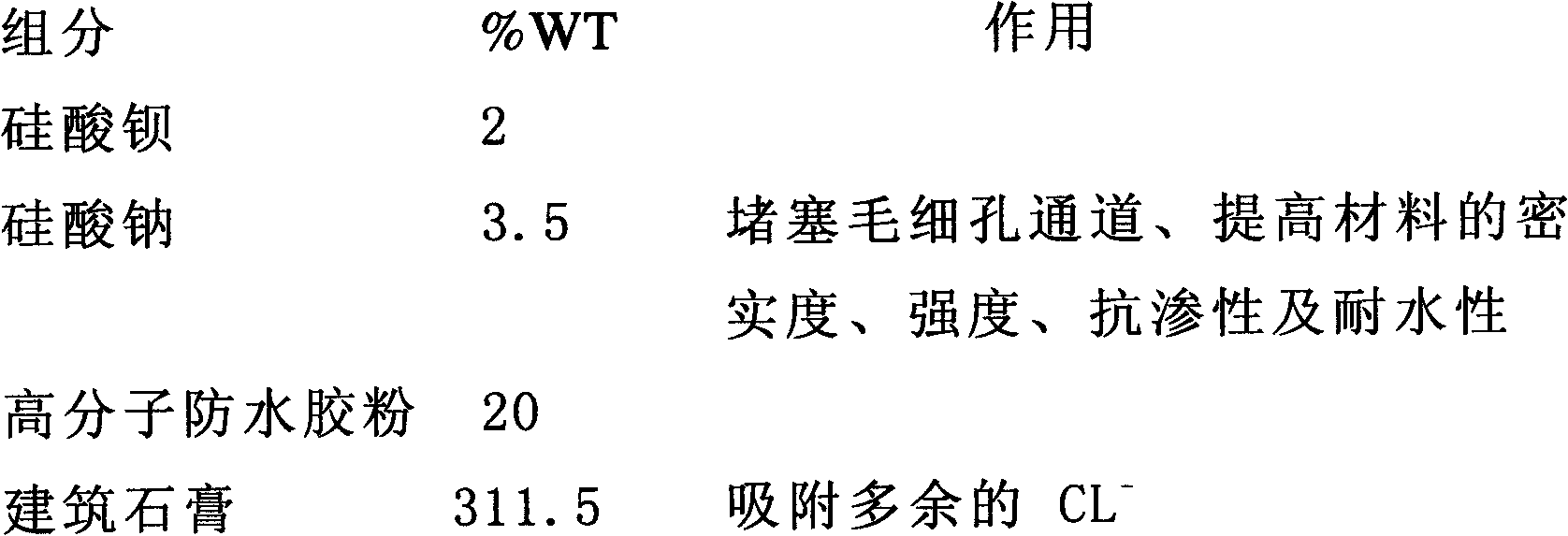

[0034] In the present embodiment, this magnesite modifier is made up of following composition:

[0035]

[0036]

[0037] The above ingredients are weighed and then stirred and mixed to make a powder.

[0038] Add the prepared improver to magnesite cement. After the magnesite cement is solidified, a hydrophobic film will be formed on the inner surface of the product, the capillary pores inside and the inner wall of the cavity, preventing the intrusion of water and reducing the impact of water on the product. erosion. At the same time, the magnesite modifier contains a considerable amount of surface active ingredients, which can fully contact and react magnesium oxide and magnesium chloride in a short period of time. The excess magnesium chloride is shielded, making it lose the opportunity to absorb moisture in the air medium, making up for the large Under the production volume, the mixing time of the slurry is short, which easily leads to the defect of insufficient mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com