Material for inorganic heat-insulating fireproof doors and production method thereof

A fire door, inorganic technology, applied in the field of building materials, can solve problems such as insufficiency, achieve the effects of solving deformation and moisture return, promoting chemical reaction, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

[0020] Embodiment The production of the material (door leaf panel) for the inorganic heat-insulating fireproof door of the present invention

[0021] The material for producing the inorganic heat-insulating fireproof door of the present invention comprises the following steps:

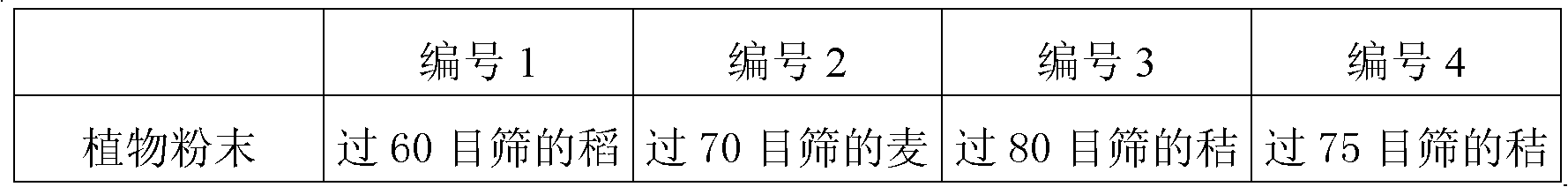

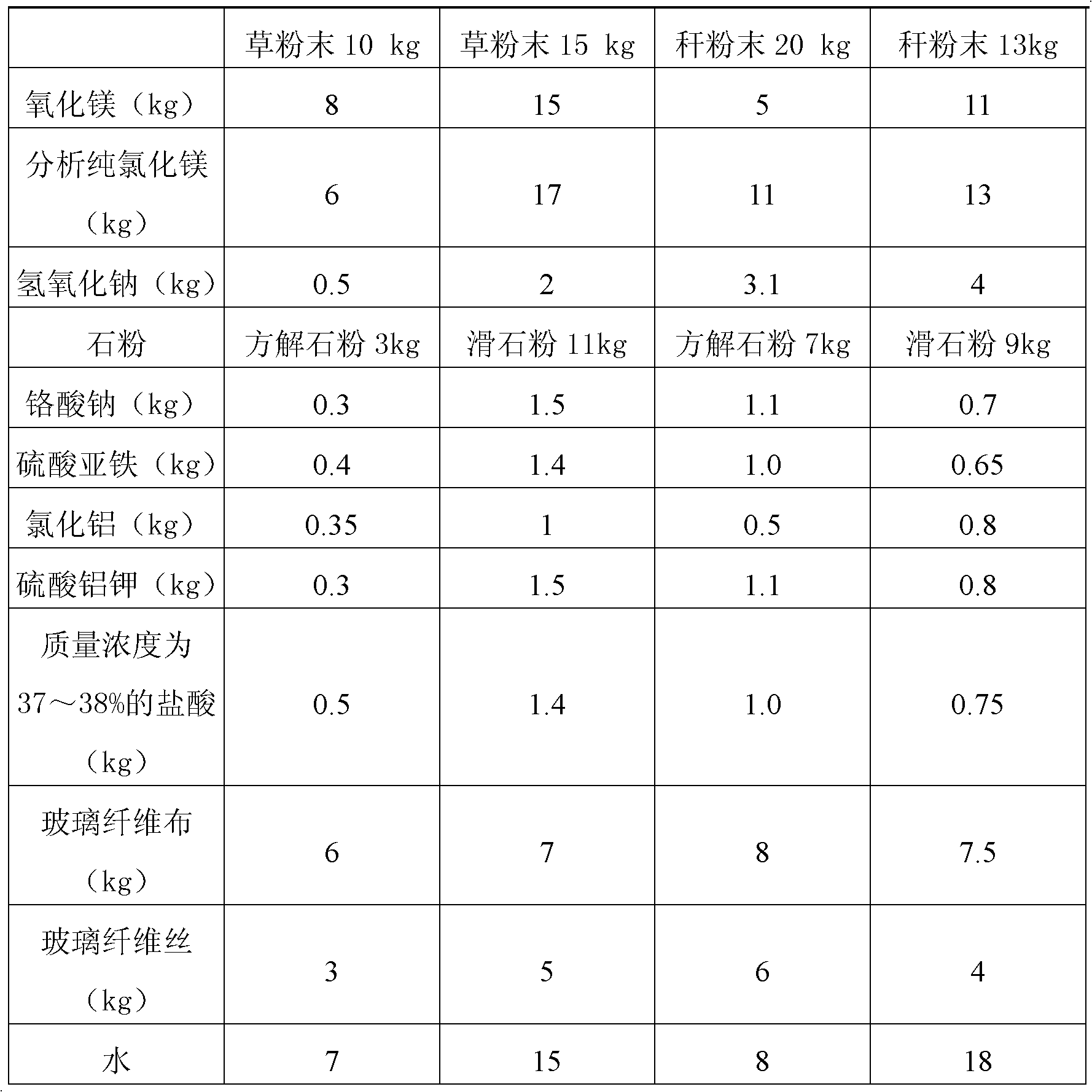

[0022] a. Preparation of slurry: Take 6-18 parts of magnesium chloride, 8-15 parts of magnesium oxide, 7-18 parts of water, 9-20 parts of plant powder passed through a 60-80 mesh sieve, calcite powder or talcum powder according to the weight ratio 2.5 to 13 parts, mixed to make a slurry;

[0023] b. Preparation of modifier: Take 0.5-4 parts of sodium hydroxide, 0.3-1.5 parts of sodium chromate, 0.3-1.5 parts of ferrous sulfate, 0.3-1 part of aluminum chloride, and 0.3-1 part of potassium aluminum sulfate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com