Preparation method of ferrous gluconate

A technology of ferrous gluconate and gluconic acid, applied in the fields of pharmacy and chemistry, can solve problems such as being difficult to meet the requirements of energy saving, high efficiency and environmental protection of industrial enterprises, and achieve the effects of shortening production time, reducing energy consumption and saving processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

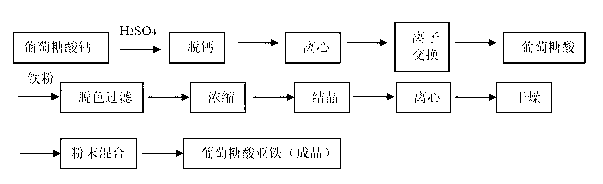

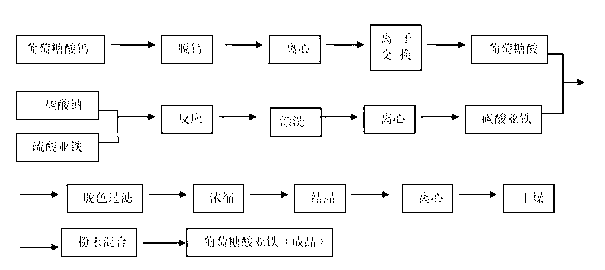

[0055]according to figure 1 Shown preparation process flow prepares ferrous gluconate:

[0056] 1. Calcium gluconate 650kg, add 25% sulfuric acid based on calcium gluconate weight, react 2 hours time, centrifugal, supernatant passes through 732 sulfonic acid base cation exchange resins and 711 quaternary ammonium base anion exchange resins sequentially, and effluent is gluconic acid solution;

[0057] II. In the described gluconic acid solution that step I obtains, add 100kg iron powder (being equivalent to 15.38% of calcium gluconate weight), react 2.5 hours under 93 ℃, pH=4.3 condition, filter, filtrate decolorizes through active carbon, Concentrate, crystallize, centrifuge, dry, get ferrous gluconate, according to the method for content determination under Chinese Pharmacopoeia 2010 edition two ferrous gluconate items, measure the content of ferrous gluconate, the results are shown in Table 5.

Embodiment 2

[0059] 1. with the step 1 of embodiment 1;

[0060] II. In the gluconic acid solution obtained in step I, add 97.5kg iron powder (equivalent to 15% of the weight of calcium gluconate), react at 90°C and pH=4.1 for 3 hours, filter, and decolorize the filtrate through activated carbon , concentration, crystallization, centrifugation, drying, get ferrous gluconate, according to the method for content determination under the two ferrous gluconate items of Chinese Pharmacopoeia version in 2010, measure the content of ferrous gluconate, the results are shown in Table 5.

Embodiment 3

[0062] 1. with the step 1 of embodiment 1;

[0063] II. In the described gluconic acid solution that step I obtains, add 78kg iron powder (being equivalent to 12% of calcium gluconate weight), react 3 hours under 100 ℃, pH=3.8 condition, filter, filtrate is decolorized through active carbon, Concentrate, crystallize, centrifuge, dry, get ferrous gluconate, according to the method for content determination under Chinese Pharmacopoeia 2010 edition two ferrous gluconate items, measure the content of ferrous gluconate, the results are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com