Method for synthesizing corrosion and scale inhibitor S-carboxyalkylthiosuccinic acid by adopting one-step method

A technology of carboxyethyl thiosuccinic acid and corrosion and scale inhibitor, which is applied in the field of industrial circulating cooling water treatment to achieve the effects of being easily biodegraded, avoiding environmental pollution and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

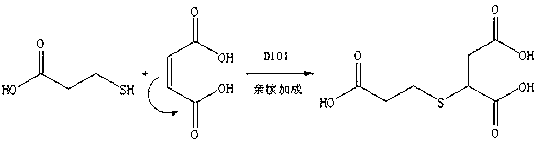

Method used

Image

Examples

Embodiment 1

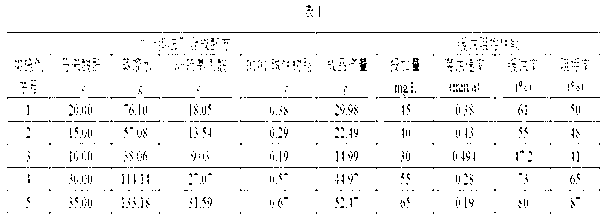

[0025] Weigh 20.00g of maleic anhydride into a three-necked flask equipped with a reflux device, add 76.10g of distilled water, and preheat to 70°C in a constant temperature oil bath to completely dissolve the maleic anhydride; then add to the above-mentioned three-necked flask 18.05g of 3-mercaptopropionic acid, add a magnetic rotor at the same time, set the rotation speed of the oil bath to 500r / min, so that the 3-mercaptopropionic acid and maleic anhydride solution are completely miscible, and then add 0.38g of D101 base The above system is heated to 125°C, heated to reflux for 3.5 hours, suction filtered while it is hot, the filtrate is placed in the refrigerator to cool to about 4°C for recrystallization, suction filtered again, the filtrate is recovered and used mechanically, and the filter cake is collected. The filter cake was placed in a freeze dryer and dried for 48 hours to obtain a white powder which was the product S-carboxyethylthiosuccinic acid. According to th...

Embodiment 2-5

[0027] The difference between Examples 2-5 and Example 1 lies in the amount of raw materials participating in the reaction and the dosage of the synthesized corrosion and scale inhibitor S-carboxyethyl thiosuccinic acid product performance test. The synthetic formulations, finished product yields and corrosion and scale inhibition properties of the five examples are shown in Table 1.

[0028] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com