A water-soluble non-woven fabric and a detergent packaging bag made of the same

A non-woven fabric and water-soluble technology, which is applied in the field of non-woven fabric and detergent packaging bags made of it, can solve the problems of inconvenient processing, machine failure, damaged detergent, etc., and achieve a balance between mechanical strength and water solubility, Good low-temperature water solubility, the effect of lowering the dissolution temperature of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

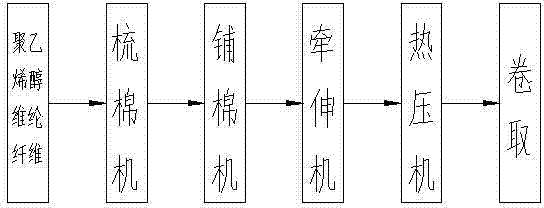

Method used

Image

Examples

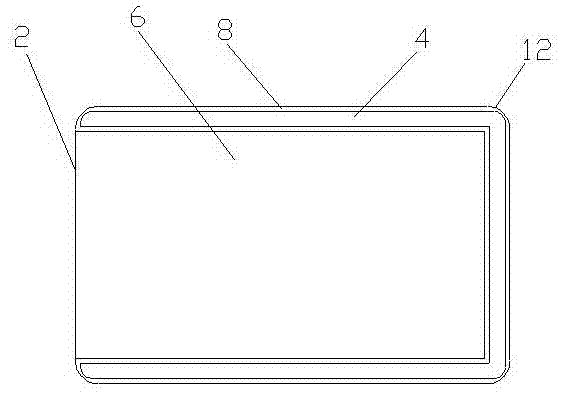

Embodiment 1

[0043] Such as figure 2As shown, the detergent packaging bag of the present invention includes a bag-shaped main body 2 composed of two layers of the above-mentioned water-soluble non-woven fabrics superimposed, and a reinforcement sheet arranged on one side of the main body 2, and the reinforcement sheet is a strip-shaped reinforcement sheet 4 . The main body 2 has a rectangular shape as a whole, with a sealed compartment 6 in the middle, and a sealing portion on three edges, and the sealing portion is a strip-shaped sealing portion 8 . Specifically, the strip-shaped sealing portion 8 extends from one long side of the main body 2 to the other long side through a short side. A strip-shaped reinforcing sheet 4 adapted to the shape of the strip-shaped sealing portion 8 is hot-pressed on the outside of the strip-shaped sealing portion 8. The strip-shaped reinforcing sheet 4 is made of a non-woven auxiliary cloth, and the raw material fiber of the auxiliary cloth includes the abo...

Embodiment 2

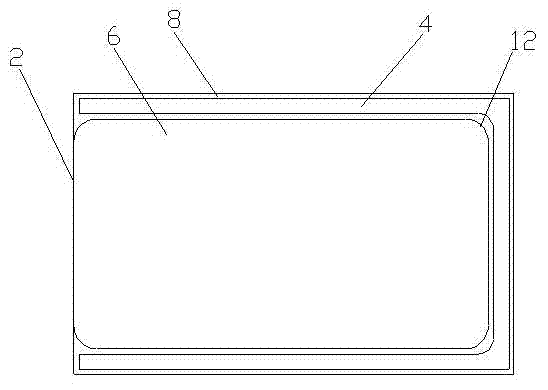

[0046] Such as image 3 As shown, the only difference from Embodiment 2 is that the four corners of the inner edge of the strip-shaped sealing part 8 are rounded corners 12, and the rounded corners 12 can be obtained by controlling the shape of the strip-shaped sealing part 8 during hot pressing. Since the corners of the inner edge of the strip-shaped seal 8 are directly in contact with the detergent, they are easier to damage than the corners of the outer edge, and once damaged, the detergent will directly leak out, so rounded corners 12 are designed on the inner edge of the strip-shaped seal 8 More immediate protection against detergents in the compartment.

Embodiment 3

[0048] Such as Figure 4 As shown, the difference from Embodiment 1 is that not only the four corners of the outer edge of the strip-shaped sealing part 8 are rounded corners 12, but also the four corners of the inner edge are rounded corners 12, which can better protect the detergent, prevent leakage and cause loss, and stick Attached to the outside of the packaging bag affects sales.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com