Engine balance shaft system

A balance shaft and engine technology, applied in the direction of eccentric shaft, inertial force compensation, etc., can solve the problems of inconvenient layout, jamming, easy deformation, etc., and achieve the effect of easy layout, lower overall height, and lower failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

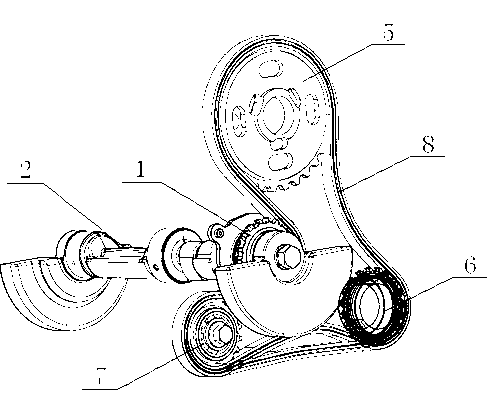

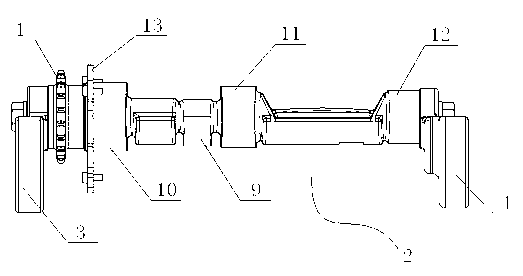

[0020] As shown in the figure, the engine balance shaft system of this embodiment includes a balance shaft 2 equipped with a balance shaft sprocket 1, a front balance weight 3 and a rear balance weight 4 are arranged on the balance shaft 2, and the balance shaft sprocket 1 is arranged on the machine. Inside the triangle formed by oil pump drive sprocket 5, crankshaft timing sprocket 6, and camshaft drive sprocket 7, the balance shaft sprocket 1, oil pump drive sprocket 5, crankshaft timing sprocket 6, and camshaft drive Sprocket 7 is on the same plane and is linked with timing chain 8, and guarantees that the rotational angular velocity of balance shaft 2 and crankshaft is consistent, and direction is opposite.

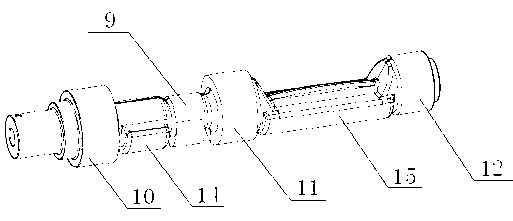

[0021] A fuel pump driving cam 9 is arranged on the balance shaft 2 . The fuel pump driving cam 9 and the balance shaft 2 are designed to be integrated, which can simplify the driving system of the fuel pump, remove parts such as gears, reduce transmission friction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com