Soft sensing method for true temperature of pyrolysis mixed products at outlet of ethylene cracking furnace

A technology of ethylene cracking furnace and real temperature, which is applied to the direction of the thermometer that gives the difference, which can solve the problems of change, no consideration of the temperature difference of the cracking furnace tube, and the estimation of the temperature difference is not necessarily accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

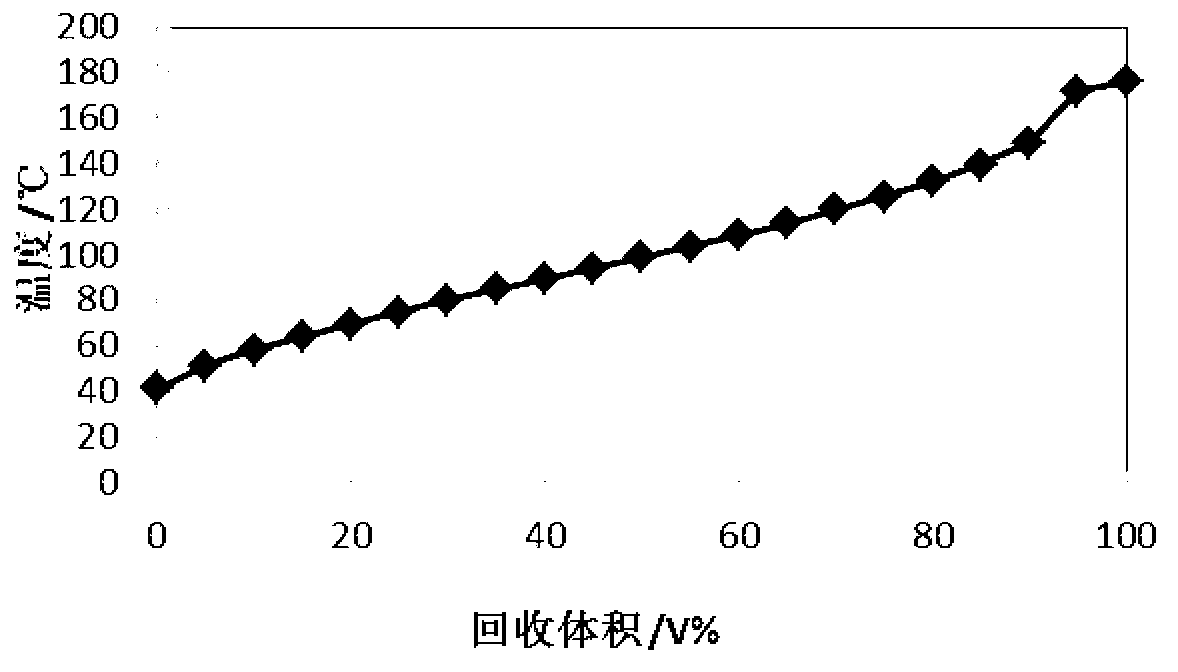

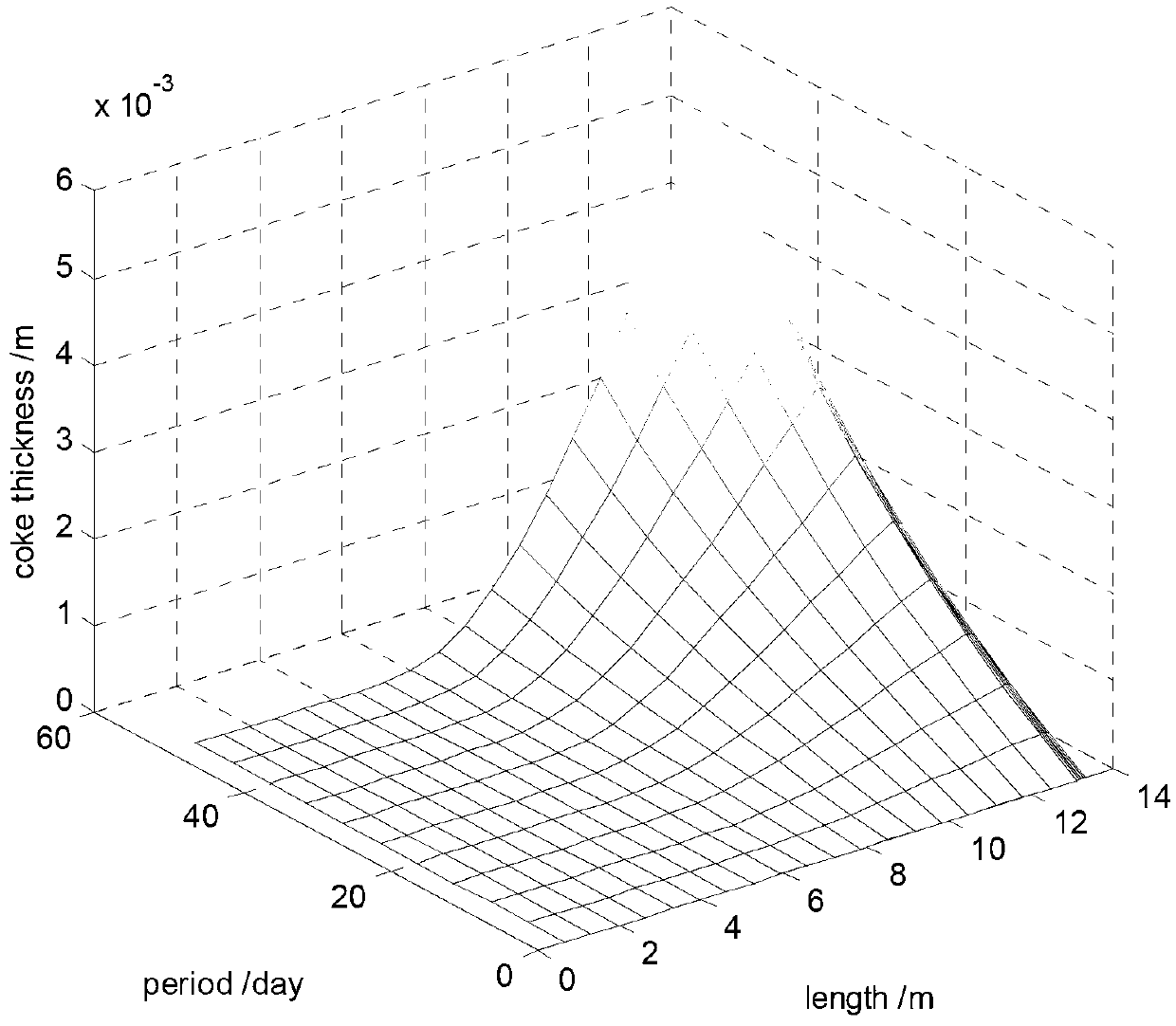

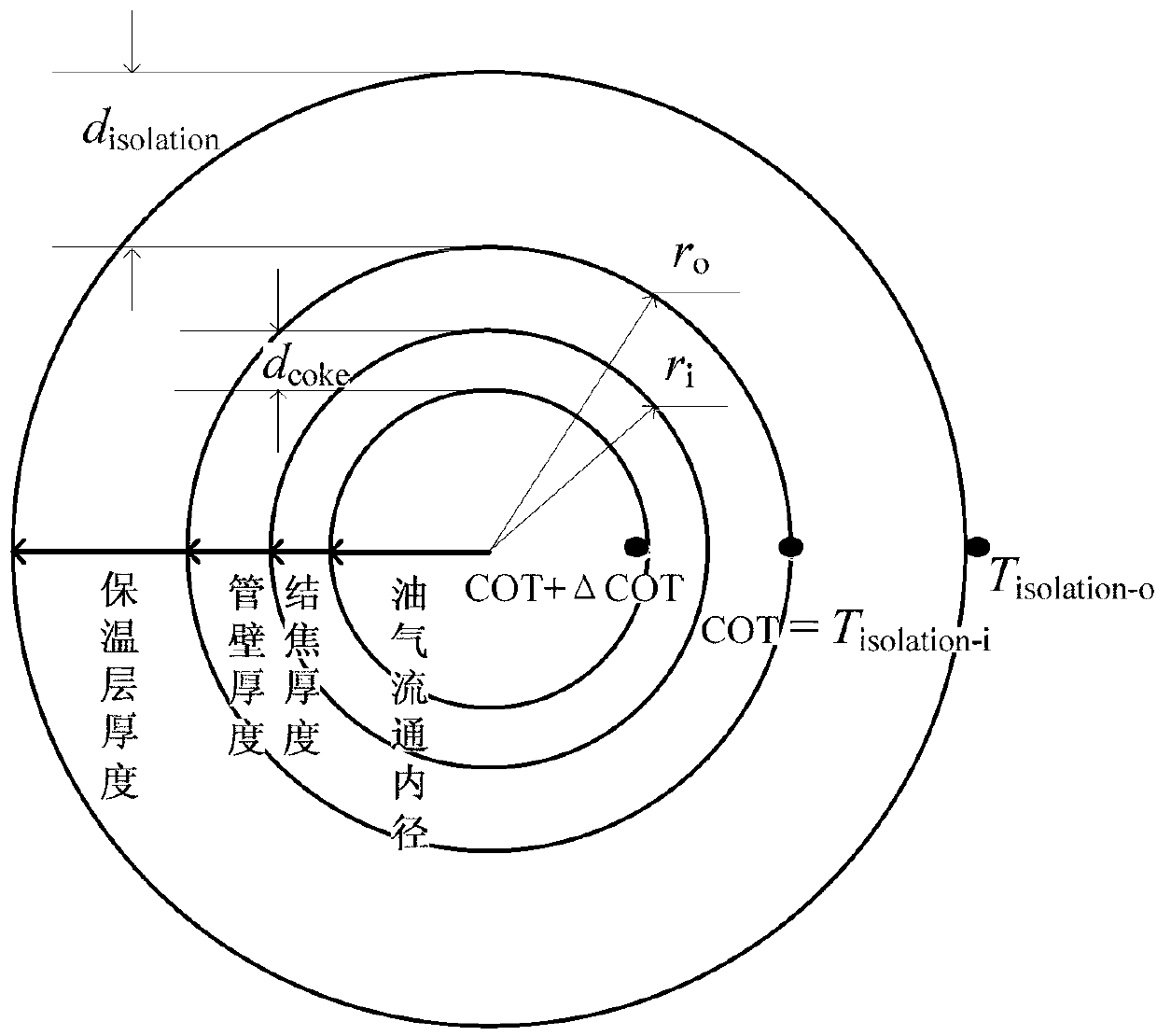

[0048] In actual production, the COT temperature measurement point is set in the adiabatic section of the ethylene cracking furnace tube. As the production progresses, the raw materials are not broken and decomposed to produce products, and the coking thickness inside the cracking furnace tube gradually increases, while the COT temperature measurement controlled by DCS The temperature at the point is constant, which is not consistent with the real temperature of the cracked product mixture. If the COT measurement temperature is used as the basis for operation and simulation, the model will inevitably be inaccurate, which will affect subsequent operation optimization and process control. The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The cracking raw material is naphtha, and the KBR-SC1 cracking furnace tube is used, a soft measurement method for the real temperature of the cracked mixed product at the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com