Cylindrical sample preparation device for measuring moisture content of green sand through capacitance method and method for measuring moisture content of green sand

A technology of wet clay sand and water content, which is applied in the preparation of test samples, material capacitance, etc., can solve the problems of low precision of water content in wet clay sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

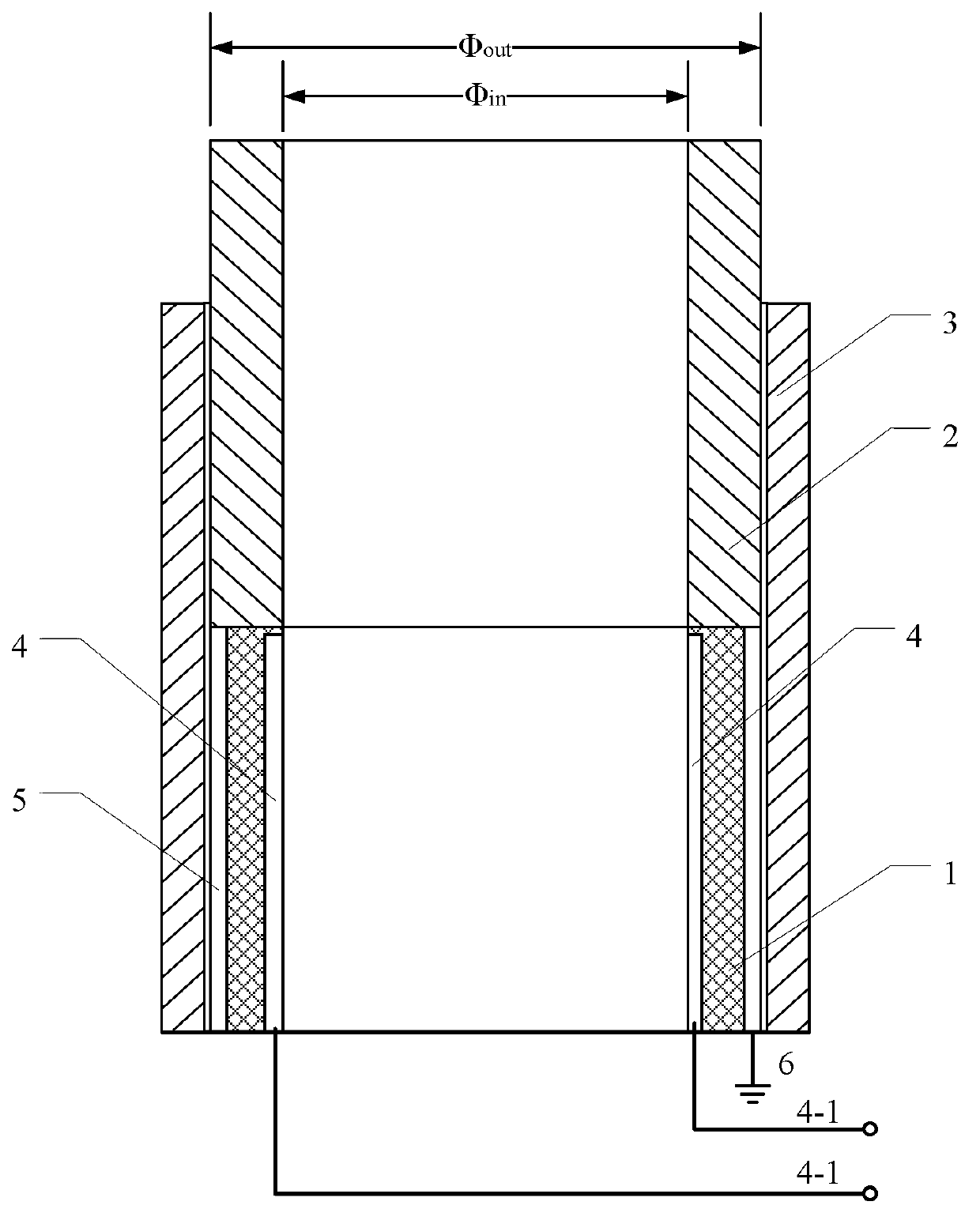

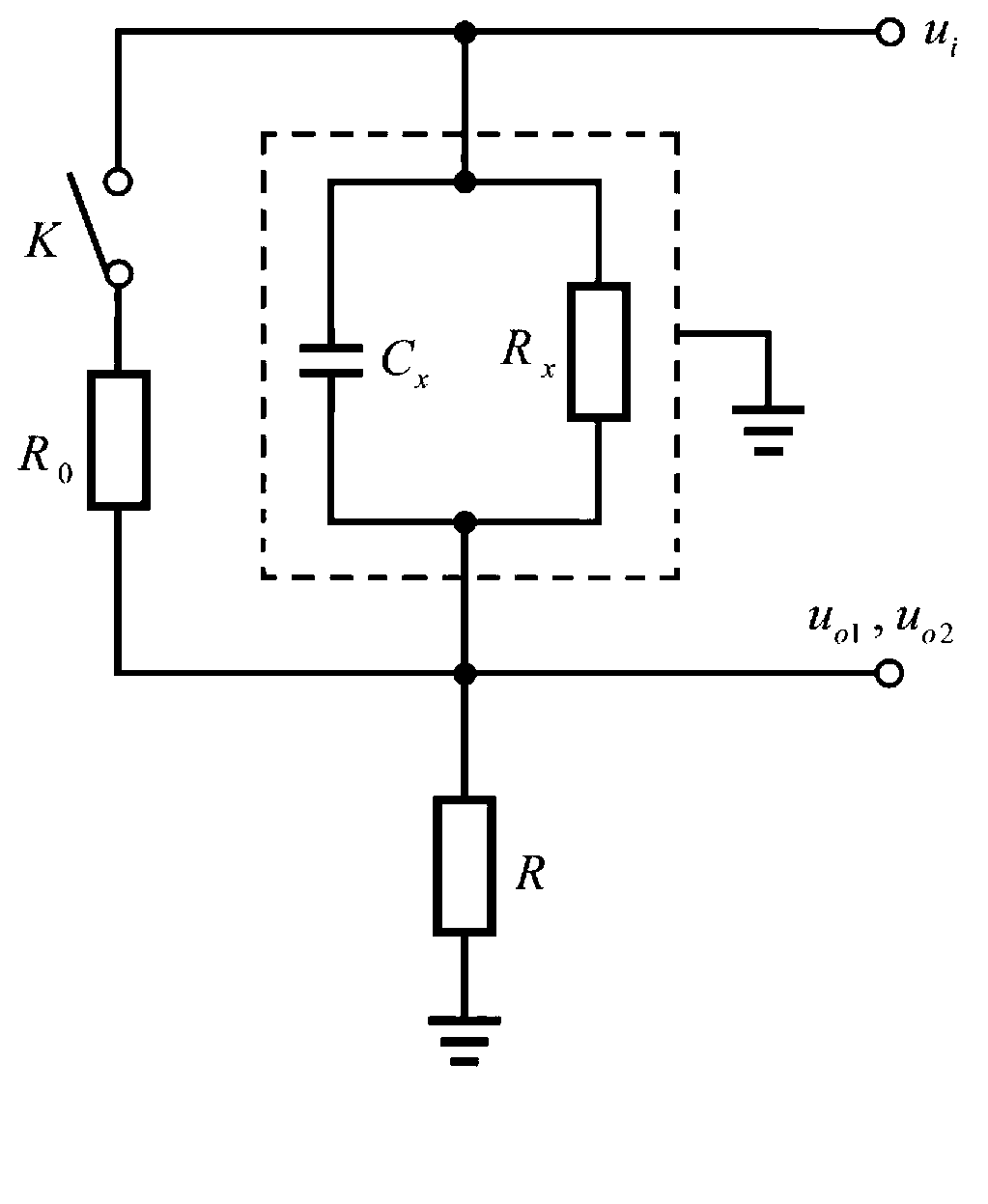

[0023] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode, a kind of cylindrical sample preparation device for measuring the moisture content of wet clay sand by capacitance method described in this embodiment mode, it comprises, main sample cylinder 1, secondary sample cylinder 2, auxiliary sample cylinder 3, two semicircular rings Excitation electrode 4, circular isolation electrode 5, isolation electrode grounding wire 6 and two excitation electrode shielding wires 4-1;

[0024] The secondary sample cylinder 2 is located directly above the main sample cylinder 1, the auxiliary sample cylinder 3 is set on the outside of the main sample cylinder 1 and the secondary sample cylinder 2, and the main sample cylinder 1, the secondary sample cylinder 2 and the auxiliary sample cylinder 3 are coaxial;

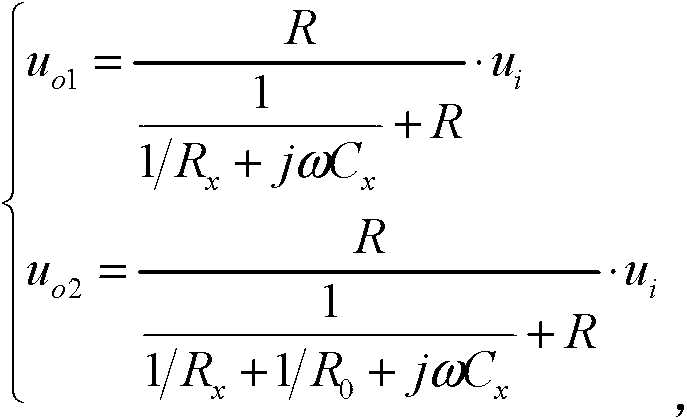

[0025] The inner wall of the main sample cylinder 1 is inlaid with two semi-circular excitation electrodes 4 of the same type, and the...

specific Embodiment approach 2

[0029] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment is a further description of Embodiment 1. The inner diameter of the secondary sample cylinder 2 described in this embodiment is 50 mm.

specific Embodiment approach 3

[0030] Specific implementation mode three: the following combination figure 1 This embodiment will be described. This embodiment is a further description of Embodiment 1. The gap between the secondary sample cylinder 2 and the auxiliary sample cylinder 3 in this embodiment is 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com