Transparent liquid impurity detection system and detection method thereof

A detection system and detection method technology, applied in the field of detection systems, can solve problems such as increased data volume, complex algorithms, and increased calculations, and achieve the effects of improving recognition speed, reducing production costs, and improving product quality and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

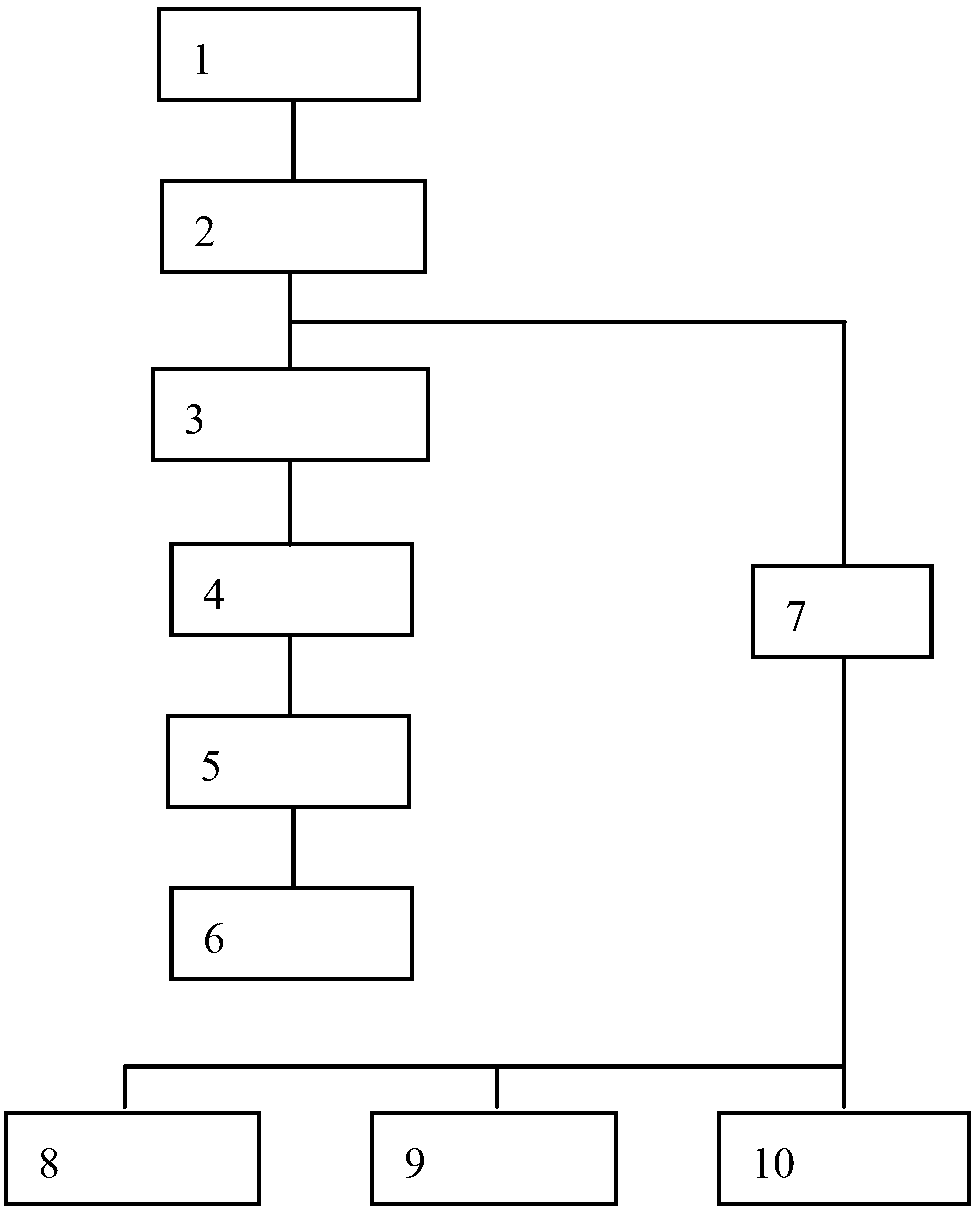

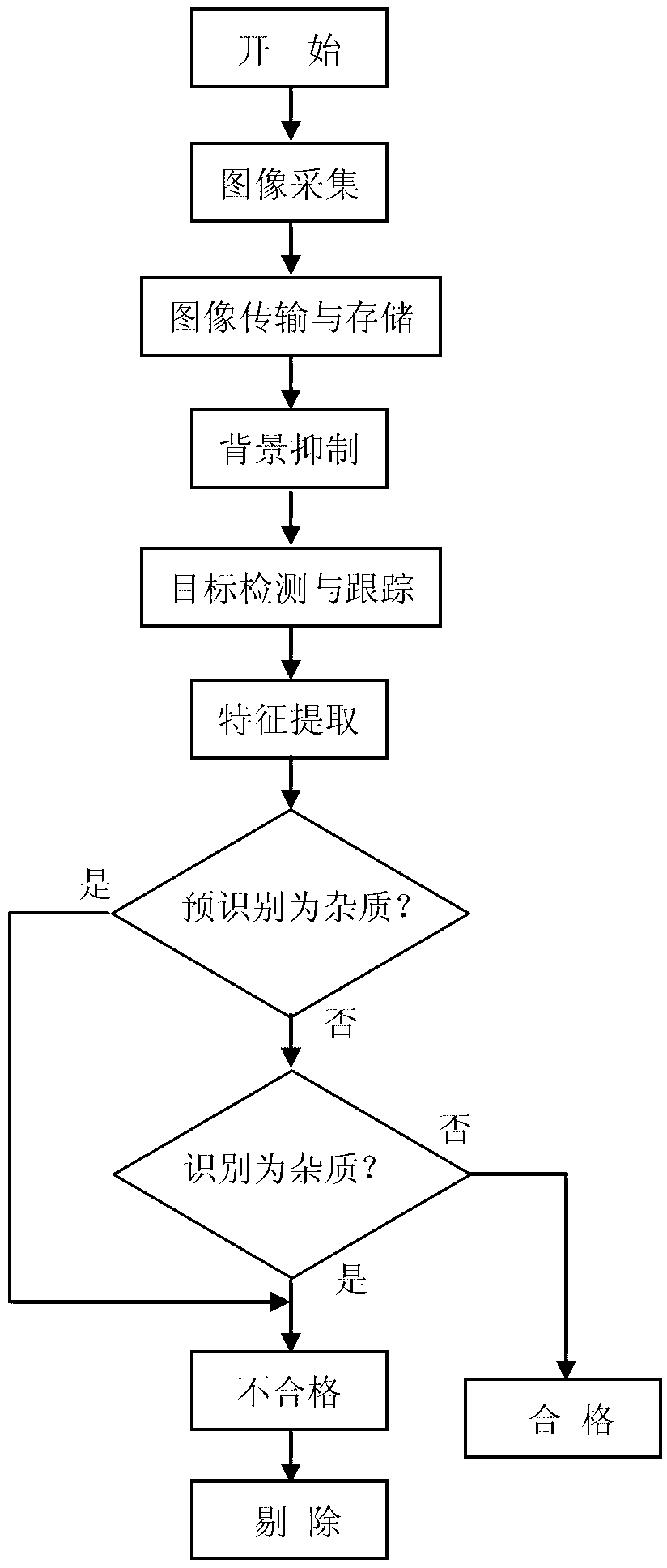

[0037] figure 1 It is a structural schematic diagram of the transparent liquid impurity detection system of the present invention, the detection system includes an operation panel 1 for on-site detection information reading, parameter setting and control; a host computer 2 is placed in the monitoring room for remote monitoring; Also includes sequentially connected DSP processors 3, parallel structure, used to increase image processing speed, and achieve information extraction through set algorithms; several CCD cameras 4, sequentially installed on the production line, and connected to the DSP processors respectively 3, and cooperate with the LED light source 6 to obtain the image of the product to be inspected; the photoelectric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com