Process optimization method of steel/aluminum laser welding brazing

A technology of process optimization and laser melting, which is applied in the field of welding, can solve problems such as difficult to capture the shape of the molten pool, less ability to give process parameters, and increased difficulty, so as to achieve shortened production cycle, strong nonlinear mapping ability, and excellent self-learning performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further elaborated below.

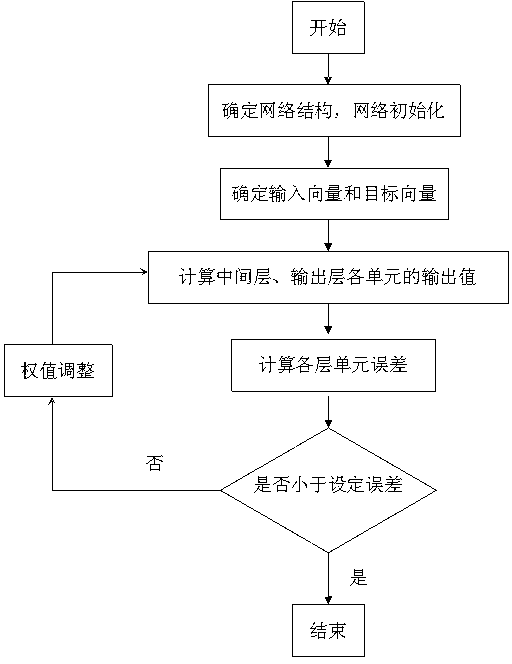

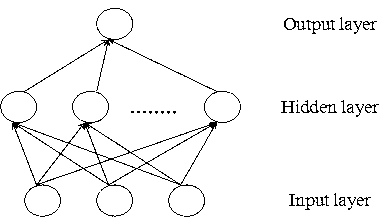

[0016] see figure 1 and 2 As shown, the specific implementation scheme of the method is illustrated below with steel / aluminum laser welding as an example:

[0017] (1) Use the finite element analysis software ANSYS to simulate the welding process, and use the APDL language that comes with the software to change the various process parameters of laser welding to obtain different molten pool shapes, so as to obtain the corresponding penetration depth under each process parameter , each process parameter is required to be within the commonly used process range, the obtained samples are as uniform and discrete as possible, the experimental result data is collected, 25 sets of experimental data are obtained from the experiment, and 20 sets of data are ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com