Oval gear variable-speed intermittent feeding mechanism for harvesting bundler

An oval gear and feeding mechanism technology, applied in agricultural machinery and implements, belts/chains/gears, packing, etc., can solve the problems of inability to achieve continuous operation, incorrect structure and working principle, etc., and achieve fixed timing and fast operation speed. , the effect of high-efficiency production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

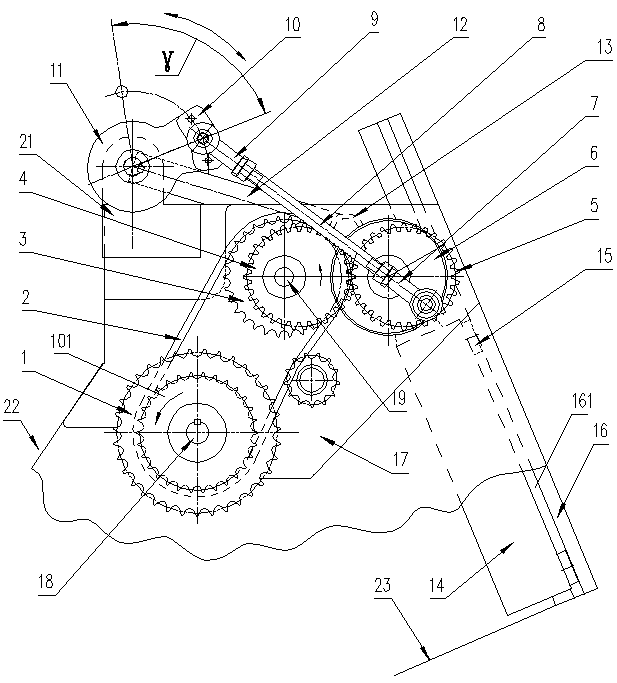

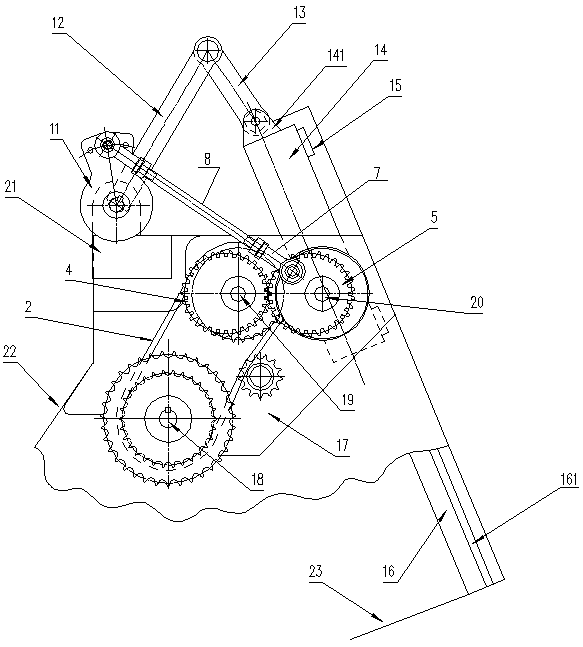

[0017] Such as figure 1 As shown, the elliptical gear unequal-speed intermittent feeding mechanism for the harvesting baler of the present invention includes a power transmission system, a reciprocating swing system, a feeding system and a fixed plate 17 for being installed on the baler, and the power transmission system passes through the reciprocating The swing system drives the feeding system to the compression chamber of the baler ( figure 1 and image 3 The below of middle compression chamber feeding port 23 is exactly compression chamber, and compression chamber is prior art, and figure is not shown) feeding. A first positioning shaft 18 is movably fixed on the fixing plate 17 , and a second positioning shaft 19 and a third positioning shaft 20 are fixed by welding.

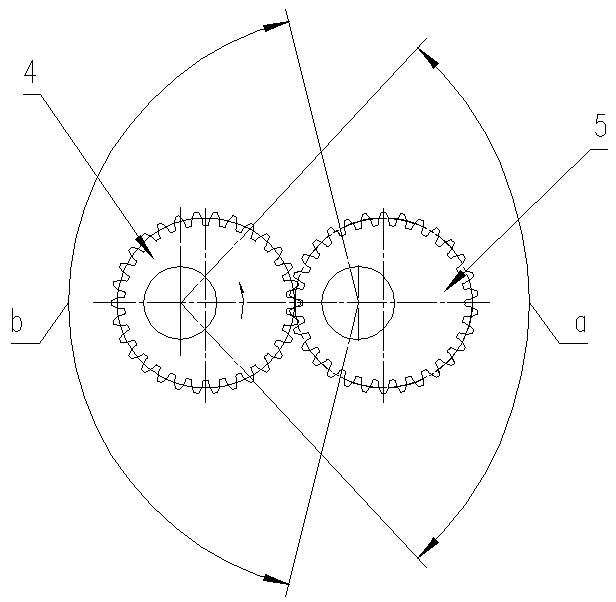

[0018] The power transmission system includes a tower wheel 1, a chain 2, a driven sprocket 3, an active elliptical gear 4 and a passive elliptical gear 5; The two positioning shafts 19 are movable and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com