Method for applying duck blood Maillard reaction essences in ham sausages

A technology of Maillard reaction and ham sausage, which is applied in the field of duck blood Maillard reaction flavor and ham sausage, can solve the problems of short shelf life, short product fragrance retention time, and high cost of raw meat, so as to extend the shelf life, The effect of low-carbon sustainable production and prolonging the fragrance retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

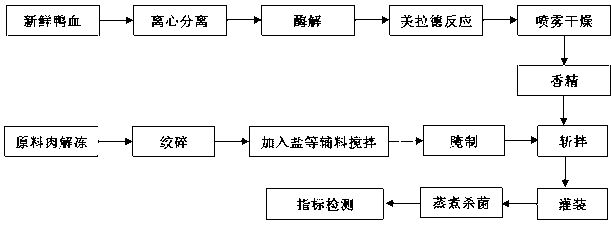

[0009] Embodiment one, as attached figure 1 the preparation process;

[0010] 1. Fresh duck blood pretreatment: ⑴ anticoagulation, take fresh duck blood, add 3.8% sodium citrate solution at 1:4 (v / v); ⑵ centrifuge, 4000r / min centrifuge for 15min, separate out the crude plasma;

[0011] 2. Preparation of enzymatic hydrolysis solution: (1) Enzymolysis, adding 5% (enzyme / plasma, v / v) alkaline protease to plasma, adjusting pH to 8.0, temperature 60°C, reacting for 3 hours; (2) Inactivating enzyme, at 100°C Heating for 10 minutes;

[0012] 3. Maillard reaction: (1) mixed reaction, mix the enzymatic hydrolysis solution with xylose and cysteine at a mass ratio of 50:1:0.2, and react at 120°C for 1 hour; (2) spray the product after the Maillard reaction Dry powder is obtained by spray drying mechanism;

[0013] 4. Ham sausage preparation: ⑴Grind the meat, thaw the raw meat, cut it into small pieces and grind it below 10°C, the diameter of the meat is about 5-7mm; ⑵Stir and marina...

Embodiment 2

[0016] Embodiment two, as attached figure 1 the preparation process;

[0017] 1. Fresh duck blood pretreatment: ⑴ anticoagulation, take fresh duck blood, add 3.8% sodium citrate solution at 1:4 (v / v); ⑵ centrifuge, 4000r / min centrifuge for 15min, separate out the crude plasma;

[0018] 2. Preparation of enzymatic hydrolysis solution: (1) Enzymolysis, adding 5% (enzyme / plasma, v / v) alkaline protease to plasma, adjusting pH to 8.0, temperature 60°C, reacting for 3 hours; (2) Inactivating enzyme, at 100°C Heating for 10 minutes;

[0019] 3. Maillard reaction: (1) mixed reaction, mix the enzymatic hydrolysis solution with xylose and cysteine at a mass ratio of 50:1:0.2, and react at 110°C for 2 hours; (2) spray the product after the Maillard reaction Dry powder is obtained by spray drying mechanism;

[0020] 4. Ham sausage preparation: ⑴Grind the meat, thaw the raw meat, cut it into small pieces and grind it below 10°C, the diameter of the meat is about 5-7mm; ⑵Stir and marin...

Embodiment 3

[0022] Embodiment three, as attached figure 1 the preparation process;

[0023] 1. Fresh duck blood pretreatment: ⑴ anticoagulation, take fresh duck blood, add 3.8% sodium citrate solution at 1:4 (v / v); ⑵ centrifuge, 4000r / min centrifuge for 15min, separate out the crude plasma;

[0024] 2. Preparation of enzymatic hydrolysis solution: (1) Enzymolysis, adding 5% (enzyme / plasma, v / v) alkaline protease to plasma, adjusting pH to 8.0, temperature 60°C, reacting for 3 hours; (2) Inactivating enzyme, at 100°C Heating for 10 minutes;

[0025] 3. Maillard reaction: (1) mixed reaction, mix the enzymatic hydrolysis solution with xylose and cysteine at a mass ratio of 50:2:0.2, and react at 110°C for 2 hours; (2) spray the product after the Maillard reaction Dry powder is obtained by spray drying mechanism;

[0026] 4. Ham sausage preparation: ⑴Grind the meat, thaw the raw meat, cut it into small pieces and grind it below 10°C, the diameter of the meat is about 5-7mm; ⑵Stir and mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com