Method for preparing meat flavor by subcritical water treatment of livestock and poultry bones

A technology of subcritical water and meat flavor, applied in food preparation, application, food science and other directions, can solve problems such as waste, reduce production costs, protect the environment, and achieve the effect of sustainable green development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

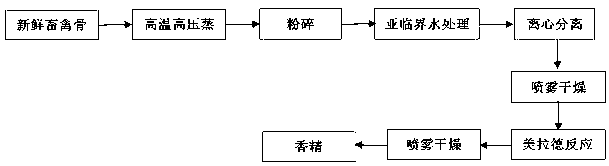

[0008] Embodiment one, its preparation process is as follows figure 1 ;

[0009] 1. Pretreatment of livestock and poultry bones: ⑴ high-temperature and high-pressure cooking, take fresh livestock and poultry bones, remove the meat, and cook at 125°C for 60 minutes; Mesh sieve;

[0010] 2. Subcritical water treatment: ⑴Reaction, configure 15% livestock and poultry bone meal solution, place in a high-pressure reactor, control the temperature of the reactor at 160°C, and the reaction time is 2h. Cool immediately after the reaction is completed; The water-treated livestock and poultry bones were centrifuged at 4000r / min for 15min. (3) Spray drying, the inlet air temperature is 200°C, the outlet air temperature is 85°C, and the bone protein peptide of livestock and poultry after subcritical water treatment and centrifugation is spray-dried to obtain dry powder;

[0011] 3. Maillard reaction: (1) mixed reaction, mix livestock and poultry bone protein peptide with xylose and cyste...

Embodiment 2

[0013] Embodiment two, its preparation process is as follows figure 1 ;

[0014] 1. Pretreatment of livestock and poultry bones: ⑴ high-temperature and high-pressure cooking, take fresh livestock and poultry bones, remove the meat, and cook at 125°C for 60 minutes; Mesh sieve;

[0015] 2. Subcritical water treatment: ⑴Reaction, configure 15% livestock and poultry bone powder solution, place in a high-pressure reactor, control the temperature of the reactor at 180°C, and the reaction time is 1.5h. Cool immediately after the reaction is completed; Livestock and poultry bones treated with critical water, centrifuged at 4000r / min for 15min. (3) Spray drying, the inlet air temperature is 200°C, the outlet air temperature is 90°C, and the bone protein peptide of livestock and poultry after subcritical water treatment and centrifugation is spray-dried to obtain dry powder;

[0016] 3. Maillard reaction: (1) mixed reaction, mix livestock and poultry bone protein peptide with xylose...

Embodiment 3

[0018] Embodiment three, its preparation process is as follows figure 1 ;

[0019] 1. Pretreatment of livestock and poultry bones: ⑴ high-temperature and high-pressure cooking, take fresh livestock and poultry bones, remove the meat, and cook at 125°C for 60 minutes; Mesh sieve;

[0020] 2. Subcritical water treatment: ⑴Reaction, configure 15% livestock and poultry bone meal solution, place in a high-pressure reactor, control the temperature of the reactor at 200°C, and the reaction time is 1h. Cool immediately after the reaction is completed; The water-treated livestock and poultry bones were centrifuged at 4000r / min for 15min. (3) Spray drying, the inlet air temperature is 200°C, the outlet air temperature is 90°C, and the bone protein peptide of livestock and poultry after subcritical water treatment and centrifugation is spray-dried to obtain dry powder;

[0021] 3. Maillard reaction: (1) mixed reaction, mix livestock and poultry bone protein peptide with xylose and cys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com