Fluctuating wind generating device

A technology of generating device and pulsating wind, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of not obtaining sorting results and reducing the effect of spiral radial zoning. , to achieve the effect of perfect adjustment plan, accurate adjustment and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

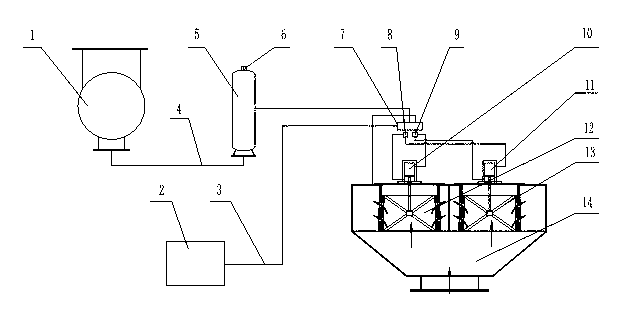

[0012] The following structural drawings further describe an embodiment of the present invention:

[0013] Such as figure 1 As shown, the pulsating wind generating device is mainly composed of an air compressor 1, a PLC solid state relay 2, a high-pressure airflow output pipe 4, a high-pressure air bag 5, an electromagnetic reversing valve 7, a three-way joint 8, a three-way joint 2 9, and a high-pressure cylinder One 10, high-pressure cylinder two 11, air valve one 12, air valve two 13, low-pressure air chamber 14 constitute; described three-way joint one 8 one end is connected with the upper interface of high-pressure cylinder one 10, and the other end is connected with high-pressure cylinder two 11 One end of the three-way joint two 9 is connected to the upper interface of the high-pressure cylinder two 11, the other end is connected to the lower interface of the high-pressure cylinder one 10, and the inlets of the two three-way joints are respectively connected to the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com