Sand-mould casting system

A technology of sand casting and sand molds, which is applied in foundry workshops, casting equipment, safety devices, etc., can solve the problems of failure to realize intelligent control, low production efficiency, and high labor intensity, and achieve small impact, high production efficiency, and labor intensity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

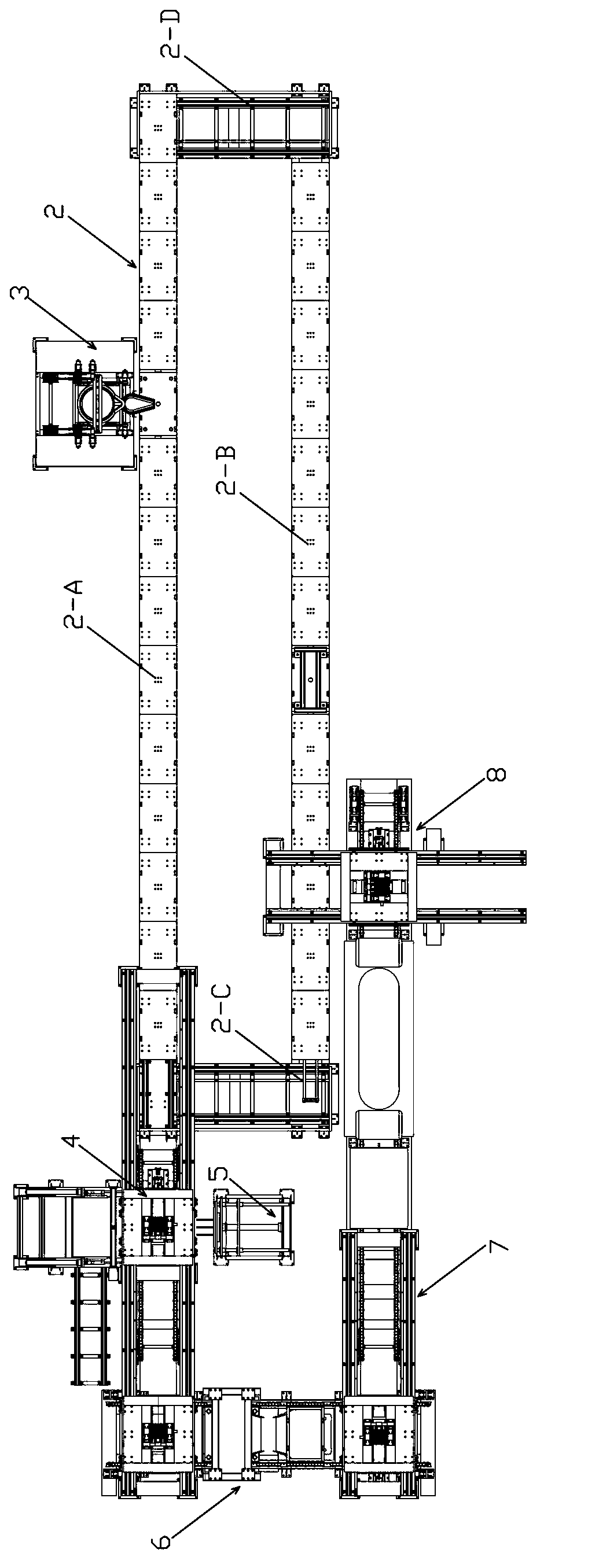

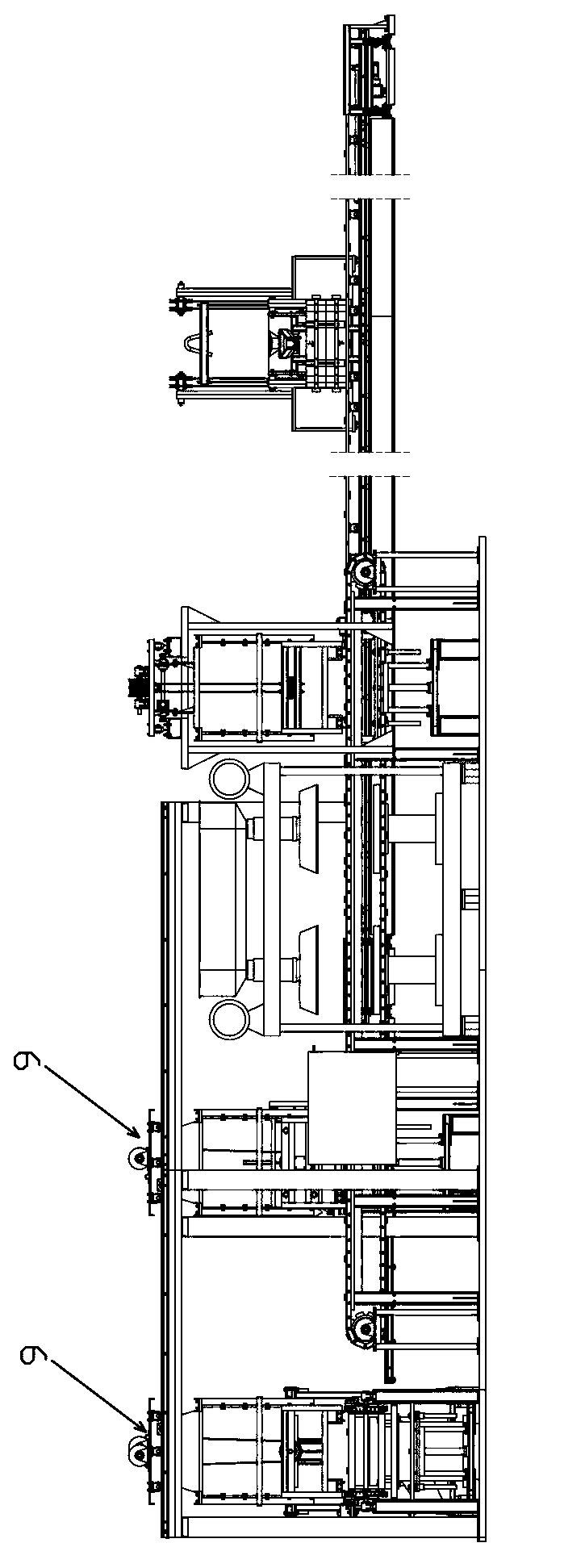

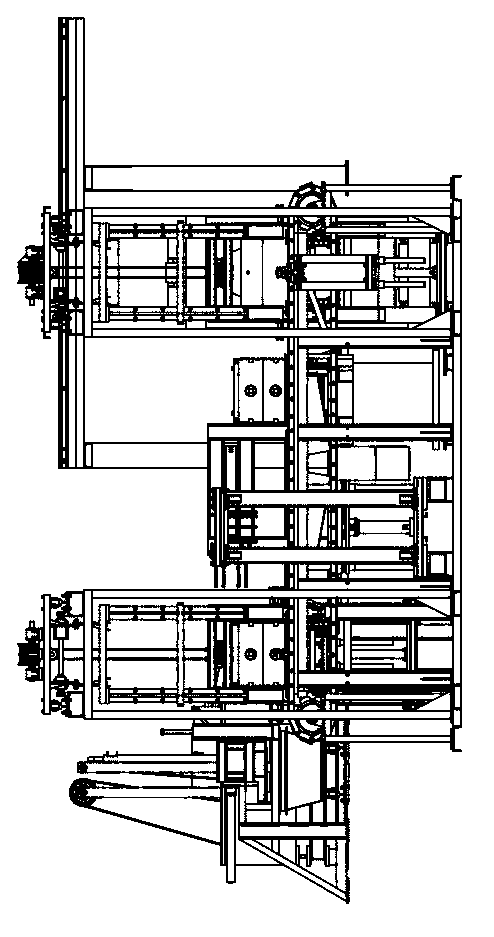

[0098] Embodiment 1: see Figure 1-3 The automatic sand casting system of this embodiment mainly includes the following parts: iron mold sand mold 1, combined rail 2, weighing casting device 3, parting mold turning device 4, mold turning and ejecting device 5, sand shaking device 6 , temperature control and sand injection molding device 7, turning box mold clamping device 8, gantry crane 9, combined track 2 includes casting light rail line 2-A (top) and mold clamping light rail line 2-B (bottom) arranged in parallel 2. Two horizontal light rail lines 2-C (left) and 2-D (right) are arranged in parallel for rail transition. The two horizontal light rail lines are respectively vertically connected to the casting light rail line 2-A (upper) and the mold-closing light rail line At both ends of 2-B (bottom), the four light rail lines are in a rectangular shape; one side of the casting light rail line is installed with a casting station, that is, a weighing casting device 3, and the ...

Embodiment 2

[0180] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the weighing casting device of this embodiment is a slide rail type structure, that is, during the casting process, the sand box, that is, the iron mold sand mold, can not be moved, The sliding of the recasting device is used to adjust the positional relationship between it and the sand box.

[0181] see Figures 66-71 , the present embodiment does not have the support foot in embodiment 1, and a motor mounting plate 3-40 is fixedly installed under a steel bar of the base 3-1, and a walking motor 3-41 is fixedly installed on this mounting plate 3-40, walking The output shaft of the motor 3-41 is fixedly provided with a gear 3-42.

[0182] Two slide rails 3-43 are laid below the base 3-1, and the bottoms of the two slide rails 3-43 (along the length direction) are vertically fixedly connected with multiple concave steel bars 3-44, one of which is a slide rail 3-43 A tooth bar 3-45 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com