Novel manufacturing method of maintenance-free chain

A manufacturing method and maintenance-free technology, which is applied in the field of chain manufacturing, can solve problems such as unsatisfactory customer use, and achieve the effects of enhancing hardness, improving fatigue performance, improving rust resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

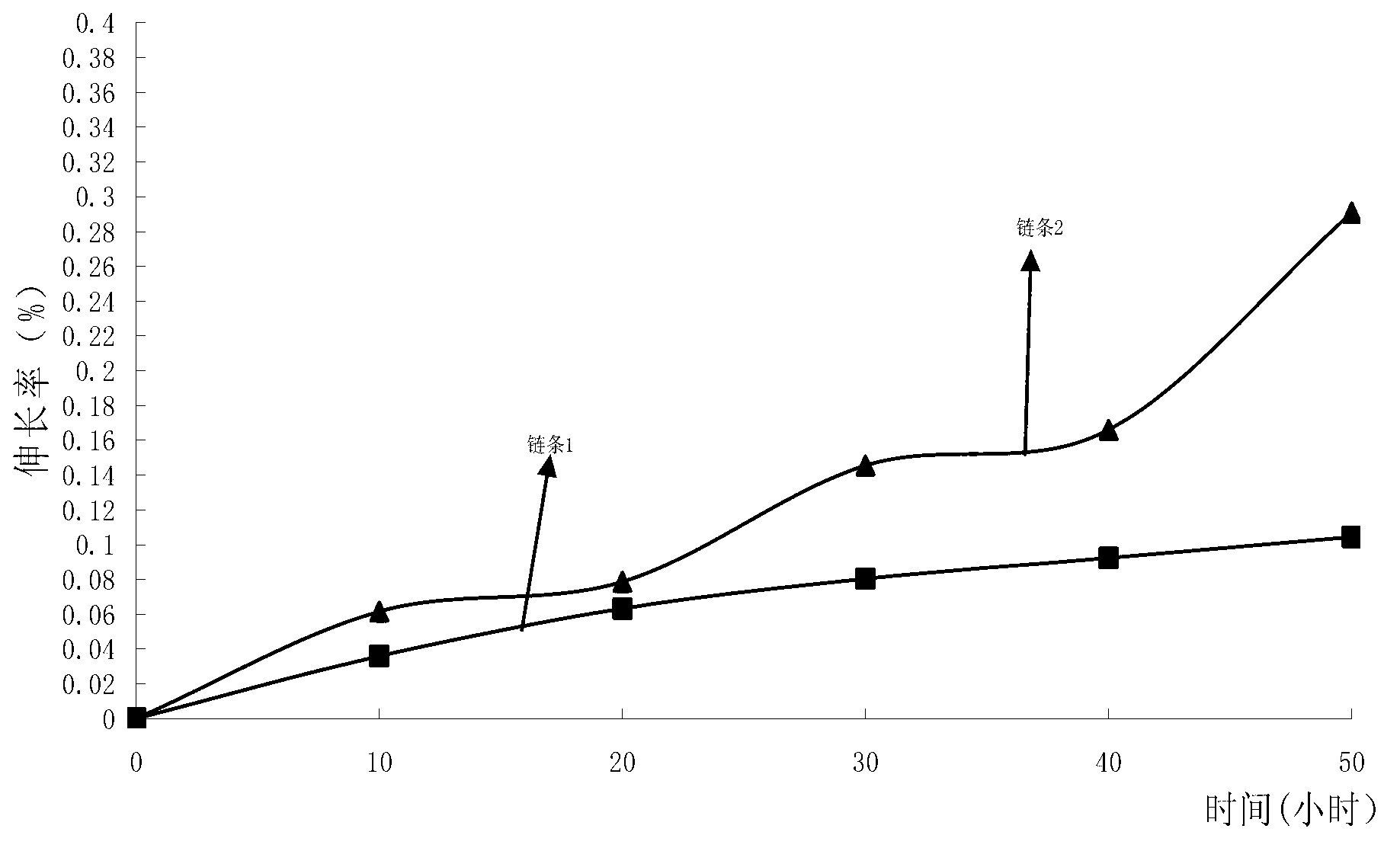

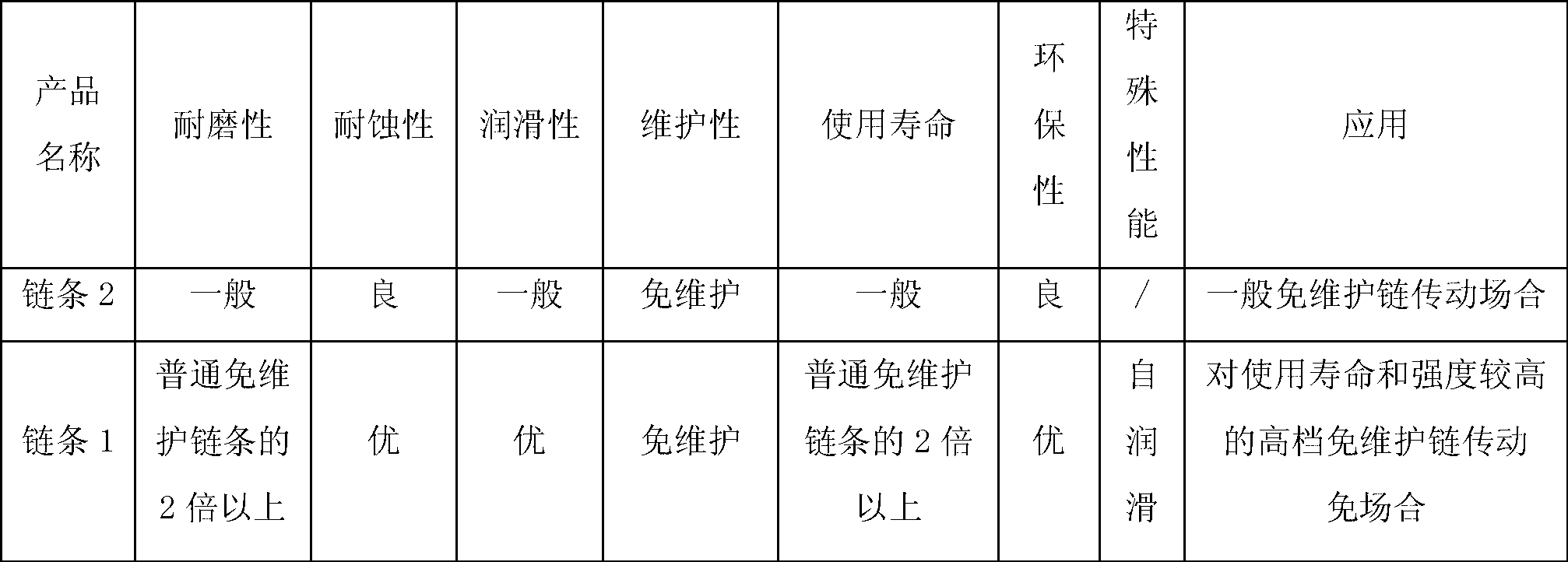

[0013] Embodiment 1: In the manufacturing method of the new maintenance-free chain in this embodiment, the chain plates and rollers constituting the chain are respectively processed according to the following process steps: (1) forming; (2) heat treatment; (3) polishing; (4) Surface treatment (such as blackening, flange, nickel plating, etc.), the pin shaft that constitutes the chain is processed according to the following process steps: (1) forming; (2) heat treatment; (3) polishing; (4) hard chrome plating on the surface ; Process the sleeve that constitutes the chain according to the following process steps: select atomization powder making→powder batching→warm pressing forming→high temperature sintering→heat treatment→sand blasting treatment→steam treatment→vacuum heating oil immersion, and assemble the above components, The powder ingredients are prepared according to the ratio of nickel powder 3%, molybdenum powder 1%, carbon powder 0.3%, and iron powder 95.7%, and the po...

Embodiment 2

[0018] Embodiment 2: In the manufacturing method of the new maintenance-free chain in this embodiment, the chain plates and pin shafts constituting the chain are respectively processed according to the following process steps: (1) forming; (2) heat treatment; (3) polishing; (4) Surface treatment (such as blackening, flange, nickel plating, etc.), the pin shaft that constitutes the chain is processed according to the following process steps: (1) forming; (2) heat treatment; (3) polishing; (4) hard chrome plating on the surface ; Process the sleeve that constitutes the chain according to the following process steps: select atomization powder making→powder batching→warm pressing forming→high temperature sintering→heat treatment→sand blasting treatment→steam treatment→vacuum heating oil immersion, and assemble the above components, The powder ingredients are prepared according to the ratio of nickel powder 5%, molybdenum powder 5%, carbon powder 0.6%, and iron powder 89.4%, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com