High instantaneous energy density electric discharge high speed milling power supply device

An energy density, high-speed milling technology, applied in electric machining equipment, metal processing equipment, circuits, etc., can solve the problems of low discharge energy, low power, and limit the removal efficiency of EDM materials, to increase energy density, reduce Relative loss, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

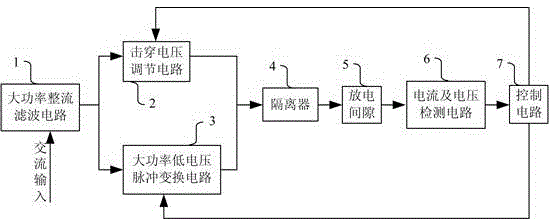

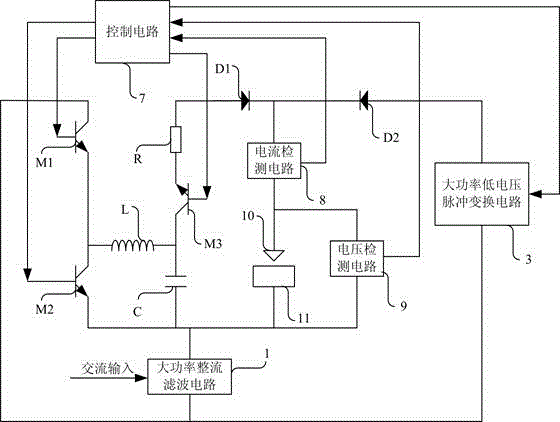

[0012] see figure 1 , The high instantaneous energy density electric discharge high-speed milling power supply device of the present invention includes a high-power rectification filter circuit 1, a breakdown voltage regulation circuit 2, a high-power low-voltage pulse conversion circuit 3, an isolator 4, and a current and voltage detection circuit 6 , Control circuit 7. The high-power rectifying and filtering circuit 1 converts the alternating current into direct current, and provides it to the breakdown voltage regulating circuit 2 and the high-power low-voltage pulse transforming circuit 3; the breakdown voltage regulating circuit 2 provides the pulse peak voltage according to the control signal of the control circuit 7. The adjustable breakdown voltage is used to break down the discharge gap. The gap breakdown voltage provided by the breakdown voltage adjustment circuit 2 can be adjusted from 100 to 1000V; the discharge gap can be adjusted by adjusting the breakdown voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com