Laser rust removing device and method based on laser texturing technology

A laser derusting and laser texturing technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy rust on the material surface, save space, reduce equipment investment, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

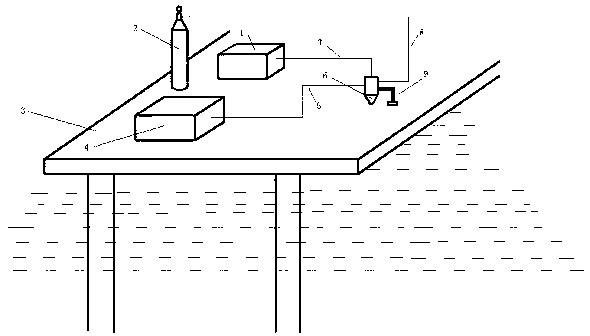

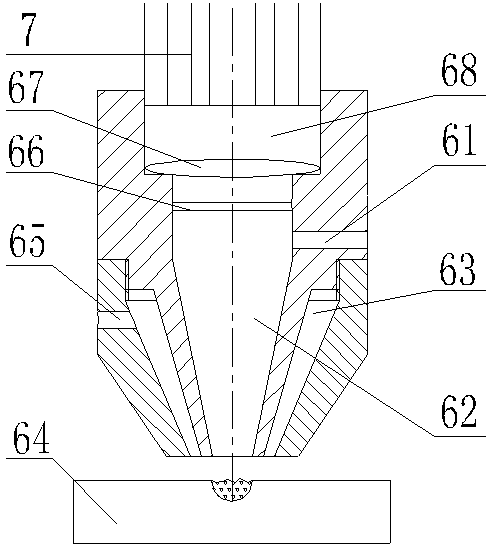

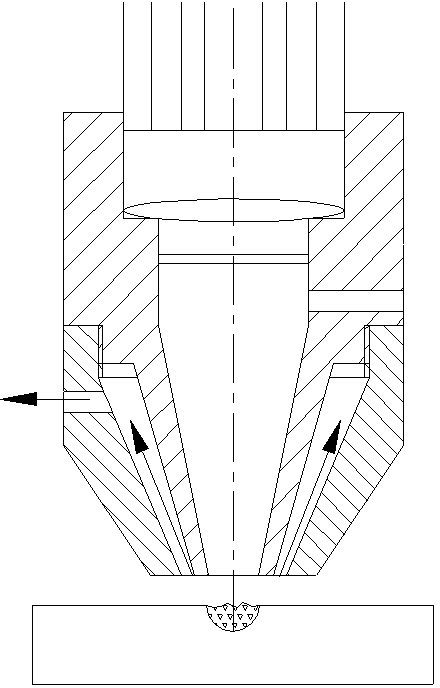

[0027] Such as figure 1 with figure 2 As shown, the device for realizing the present invention includes a laser 1, a protective gas bottle 2, a derusting head 6, a gas adsorption device 4 and a machine arm 9, the derusting head 6 is provided with a laser passage 62, and the derusting head 6. It consists of a rust removal head body and a rust removal nozzle connected to the rust removal head body. The rust removal nozzle is threaded with the rust removal head body, so that the rust removal nozzle and the rust removal head body can be realized. convenient and quick replacement; the derusting nozzle is provided with a laser channel 62, a gas adsorption channel 63 located outside the laser channel 62, and a gas adsorption tube interface 65, and the gas adsorption tube interface 65 is connected to the gas adsorption Channel 63 runs through; the derusting head body is provided with a transmission fiber interface 68, a focusing lens 67, a protective plane mirror 66 and a protective...

Embodiment 2

[0033] Such as figure 1 , Figure 5 As shown, the device for realizing the present invention includes a laser 1, a protective gas bottle 2, a derusting head 6, a gas adsorption device 4 and a machine arm 9, the derusting head 6 is provided with a laser passage 62, and the derusting The head 6 is composed of a rust removal head body and a rust removal nozzle connected to the rust removal head body. The rust removal nozzle is provided with a gas adsorption channel 63 outside the laser channel 62 and a protective gas pipe interface 61. ( Image 6 shown) and the gas adsorption tube interface 65, the protective gas tube interface 61 is connected with the laser channel 62, the gas adsorption tube interface 65 is connected with the gas adsorption channel 63; the derusting head body is provided with Transmission fiber interface 68 and focusing lens 67; the laser is connected to the transmission fiber interface 68 on the rust removal head body through the transmission fiber 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com