Full-digital automatic control fire clay mixing method and device

An all-digital, fire clay technology, applied in the direction of mixing operation control device, clay preparation device, cleaning method and utensils, etc., can solve the problems of complicated process and different formulas, reduce costs, facilitate maintenance and replacement, and reduce blockage The effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

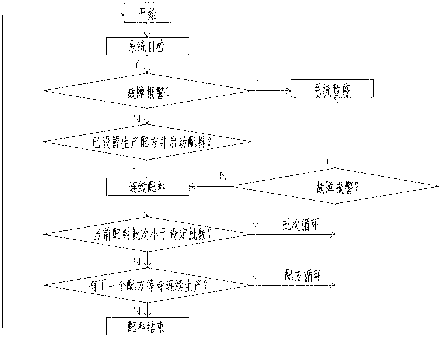

Method used

Image

Examples

Embodiment Construction

[0031] In order to ensure the accuracy of the batching weight, the present invention adopts a double-station structure, that is, the 4# station is used for the main ingredient, and the 8# station is used for the auxiliary material. In view of the characteristics of large weight of main material and relatively large absolute error value within the allowable range of precision, the feeding method of large auger is adopted to increase the feeding speed. The weight of auxiliary materials is small, the precision is high, and the control is very difficult. For this reason, a special small auger is used for feeding, which improves the feeding accuracy.

[0032] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

[0033] The fire mud batching device of full digital automatic control provided by the present invention has a structure such as figure 1 and figure 2 As shown, in v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com