Wind generating set blade mold and carbon fiber heating system of the wind generating set blade mold

A technology for wind power generators and heating systems, which is applied to household appliances, other household appliances, household components, etc., which can solve the problems of uneven heating of molds, limited service life, and inconvenient maintenance, so as to reduce weight, facilitate laying, and avoid void effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] In view of this, the object of the present invention is to provide a carbon fiber heating system and a blade mold for a wind turbine blade mold, which can not only ensure the uniformity, reliability and working life of the mold heating, but also reduce the weight and cost of the mold. And its use environment is not limited.

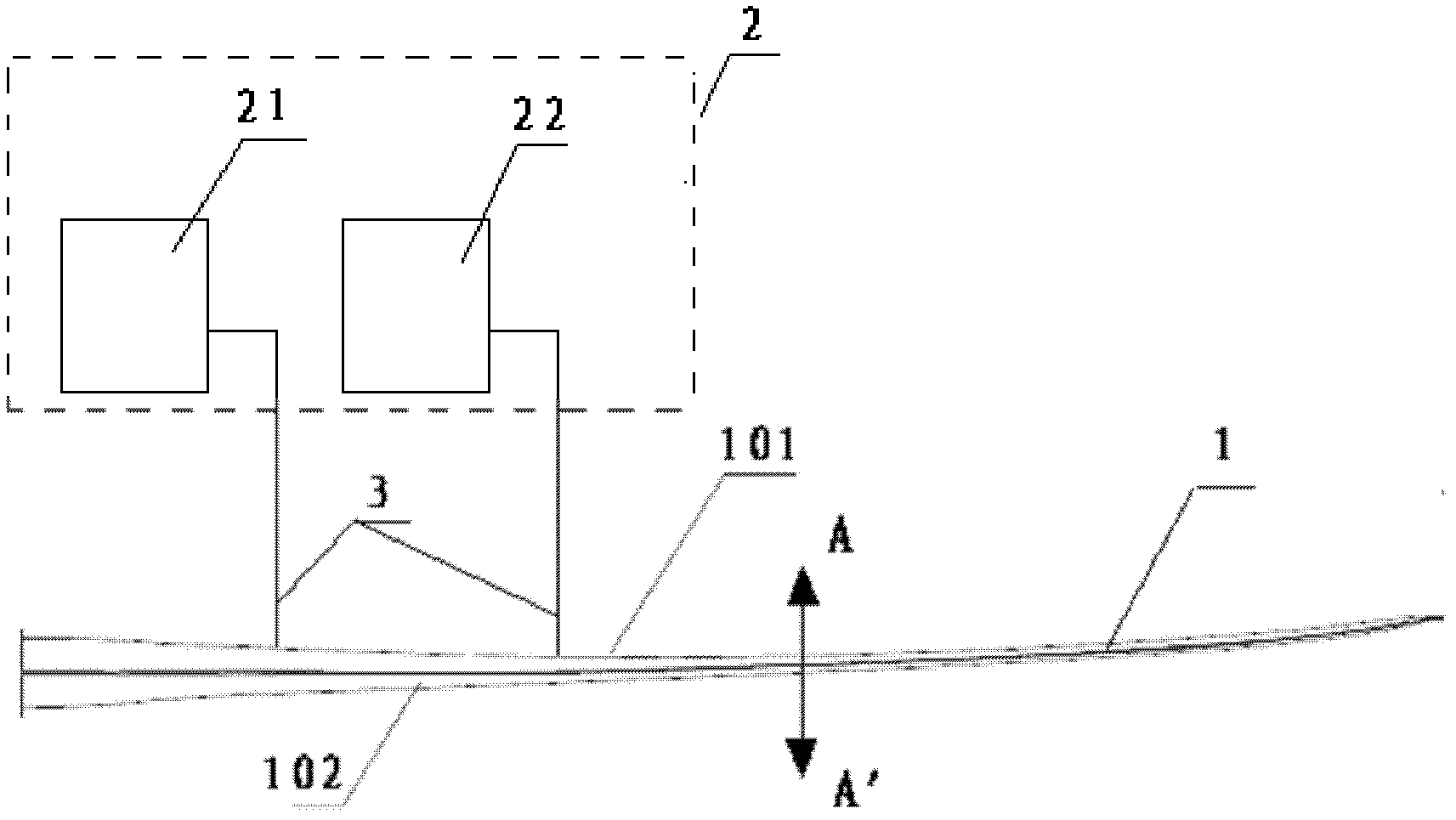

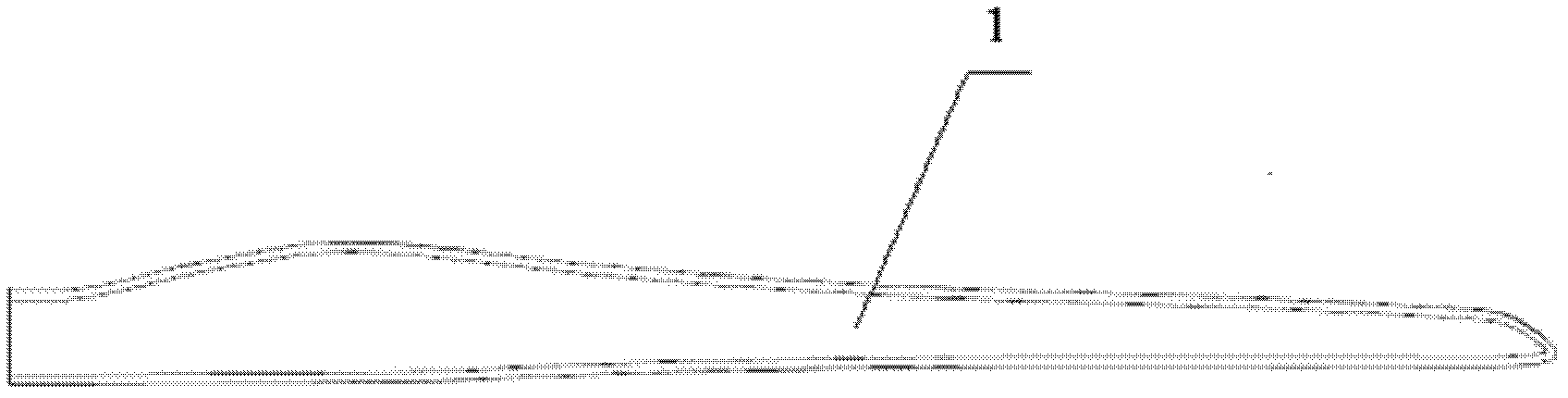

[0051] refer to Figure 1a , is the structural diagram of the carbon fiber heating system of the blade mold of the wind power generating set according to the embodiment of the present invention; Figure 1b It is a top view of the wind turbine blade mold. in, Figure 1a The front view of the blade mold is shown in .

[0052]The carbon fiber heating system described in the embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com