Method of preparing mesoporous carbon material and application of mesoporous carbon material as noble metal catalyst carrier

A mesoporous carbon and carbonization technology, which is applied in the field of preparing mesoporous carbon materials from soybeans, can solve the problems of low catalyst activity and high catalyst cost, and achieve the effects of improving effective utilization, expanding the interface, and promoting transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

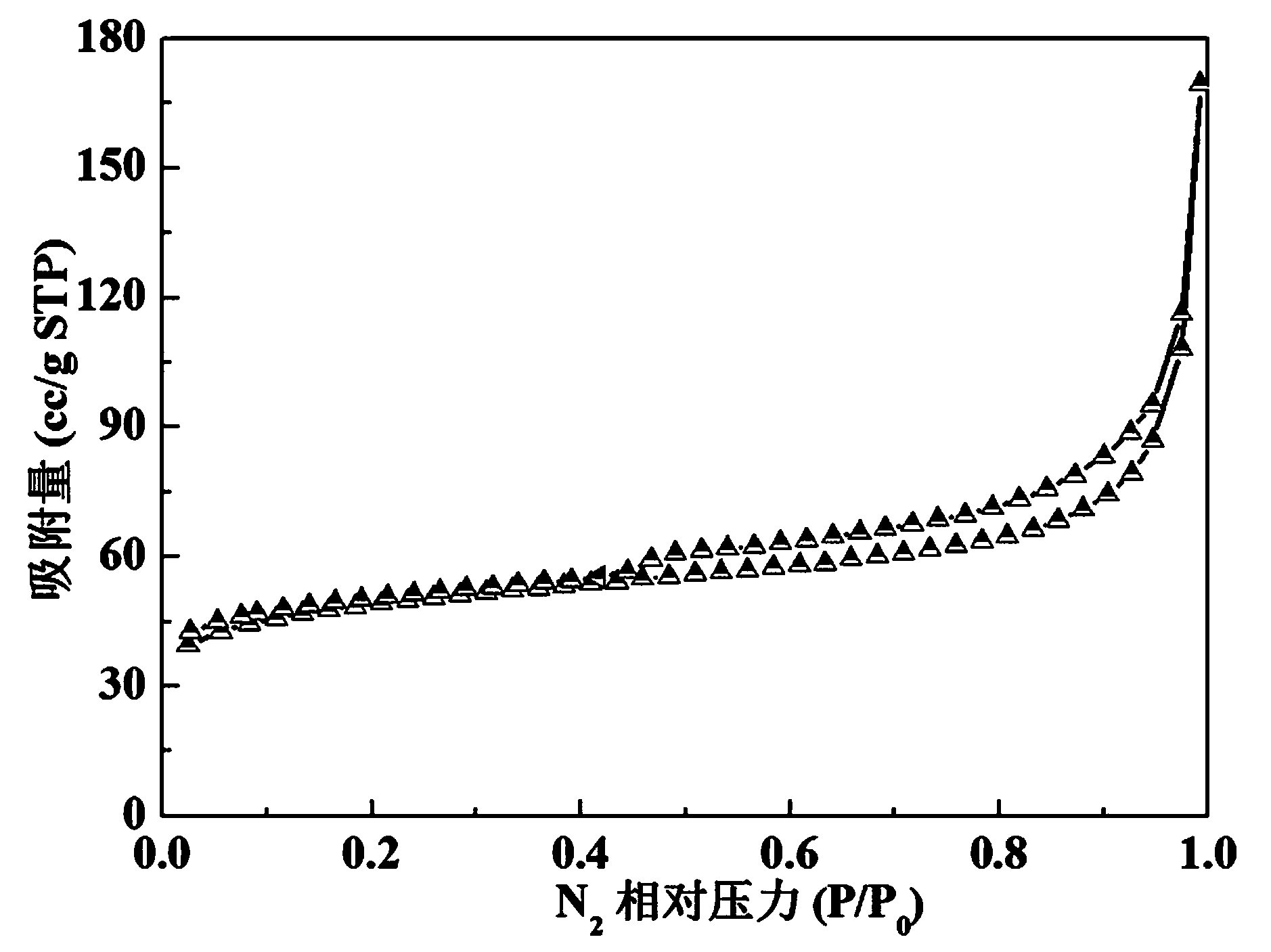

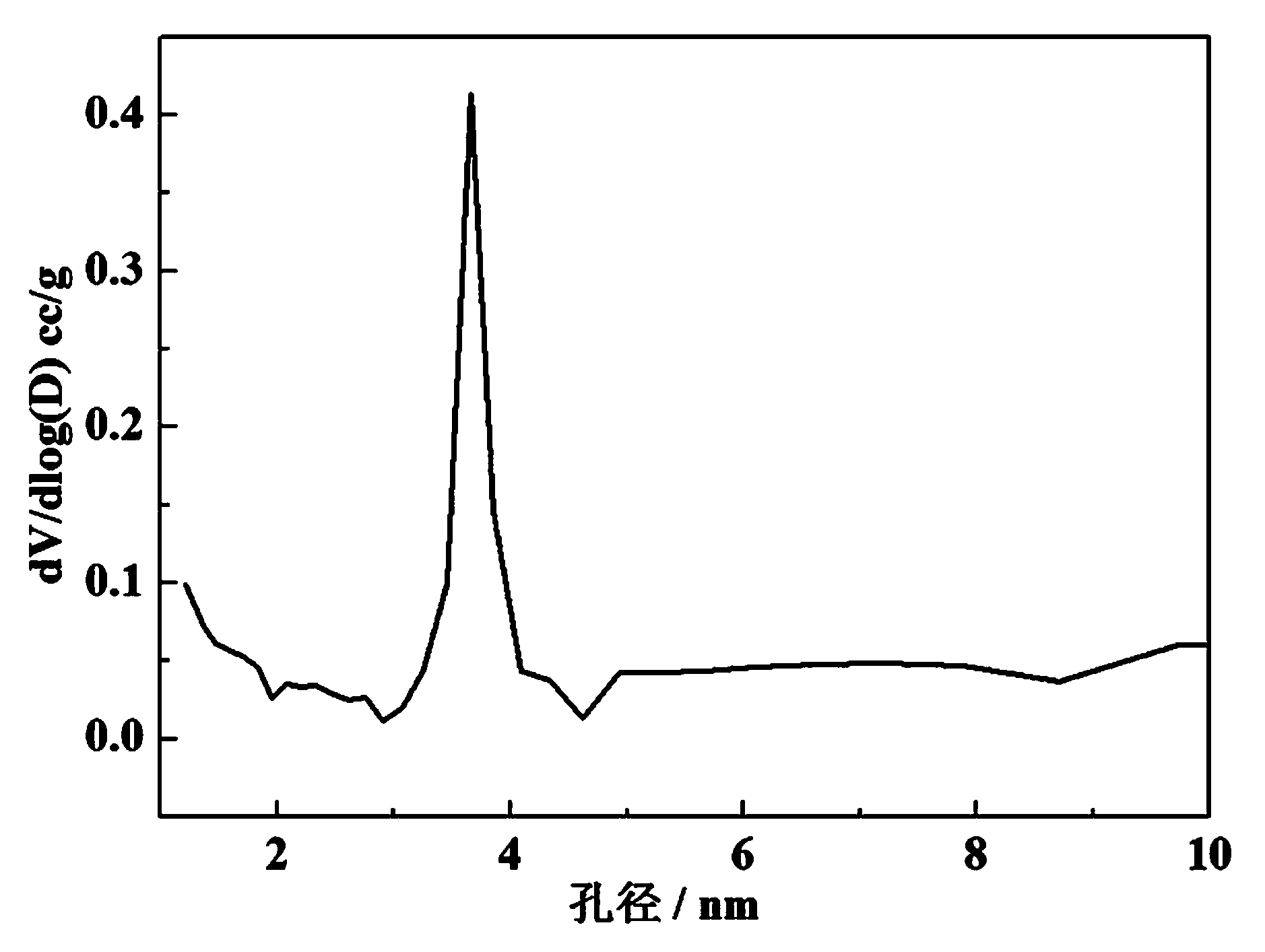

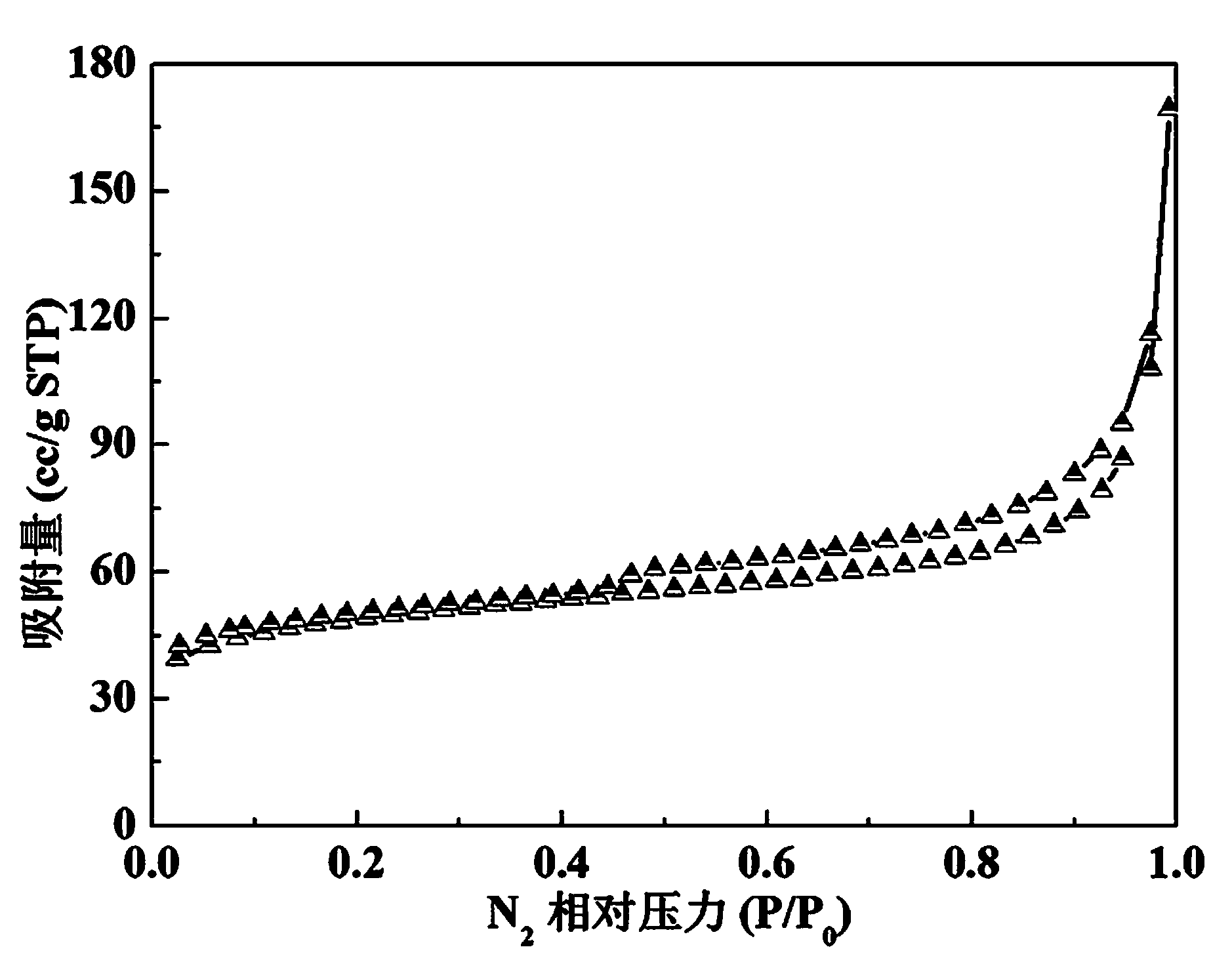

[0033] (1) Preparation of mesoporous carbon materials

[0034] Soybean was crushed and refined by ball milling, then carbonized at 800 °C for 2 h under the protection of inert gas to prepare mesoporous carbon; the mesoporous carbon was ball milled for 4 h. Weigh 2 g of ball-milled mesoporous carbon, add it to 30 ml of acetone, reflux at 60 °C for 2 h, wash, filter to remove residues during the carbonization process; place in a blast oven and dry at 60 °C for 12 h . Add to 30 ml of mixed aqueous solution of nitric acid and hydrogen peroxide (the concentration of nitric acid is 2 mol / L, H 2 o 2 The mass percentage is 3%), stirring at room temperature for 24 h to oxidize the surface of mesoporous carbon; after cleaning and filtering, dry at 60 °C in a blast oven for 12 h. Then, the surface cleaned and oxidized mesoporous carbon was protected by an inert gas, and carbonized for 2 hours at 800°C to make the carbonization more complete; finally, it was added to 30 ml of a mixed aqu...

Embodiment 2

[0038] (1) Preparation of mesoporous carbon materials

[0039] Soybeans were crushed and refined by ball milling, then carbonized at 900°C for 1.5 h under the protection of inert gas to obtain mesoporous carbon; the mesoporous carbon was milled in a ball mill for 4 h. Weigh 2 g of ball-milled mesoporous carbon, add it to 25 ml of acetone, reflux at 60 °C for 2 h, wash and filter to remove residues during the carbonization process; place in a blast oven and dry at 60 °C for 12 h ; Then join in the mixed aqueous solution of nitric acid and hydrogen peroxide of 25 ml (the concentration of nitric acid is 1 mol / L, H 2 o 2 The mass percentage is 5%), stirring at room temperature for 24 h to oxidize the surface of mesoporous carbon; after cleaning and filtering, place in a blast oven and dry at 50 °C for 12 h. Then under the protection of inert gas, secondary carbonization at 900°C for 1.5h to make the carbonization more complete; finally added to 25 ml of mixed aqueous solution of...

Embodiment 3

[0043] (1) Preparation of mesoporous carbon materials

[0044] Soybeans were crushed and refined by ball milling, and then carbonized at 1000 °C for 1 h under the protection of inert gas to obtain mesoporous carbon, which was milled by a ball mill for 4 h. Weigh 2 g of mesoporous carbon and add it to 20 ml of acetone, reflux at 55 °C for 2 h, wash and filter to remove residues during the carbonization process, place in a blast oven, and dry at 60 °C for 12 h. Then add 20 ml of mixed aqueous solution of nitric acid and hydrogen peroxide (concentration of nitric acid is 1 mol / L, H 2 o 2 The mass percentage is 10%), stirring at room temperature for 12 h to oxidize the surface of mesoporous carbon; after cleaning and filtering, dry at 50 °C for 12 h in a blast oven; , to make its carbonization more complete; the product was added to the mixed aqueous solution of 20 ml of nitric acid and hydrogen peroxide (the concentration of nitric acid is 1mol / L, H 2 o 2 The mass percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com