Improved sequencing batch primary sludge fermentation coupling denitrification device and method

A technology of primary sludge and denitrification, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. Problems such as poor sludge dewatering performance, to achieve the effect of promoting sustainability, releasing product inhibition, and reducing the release of secondary pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

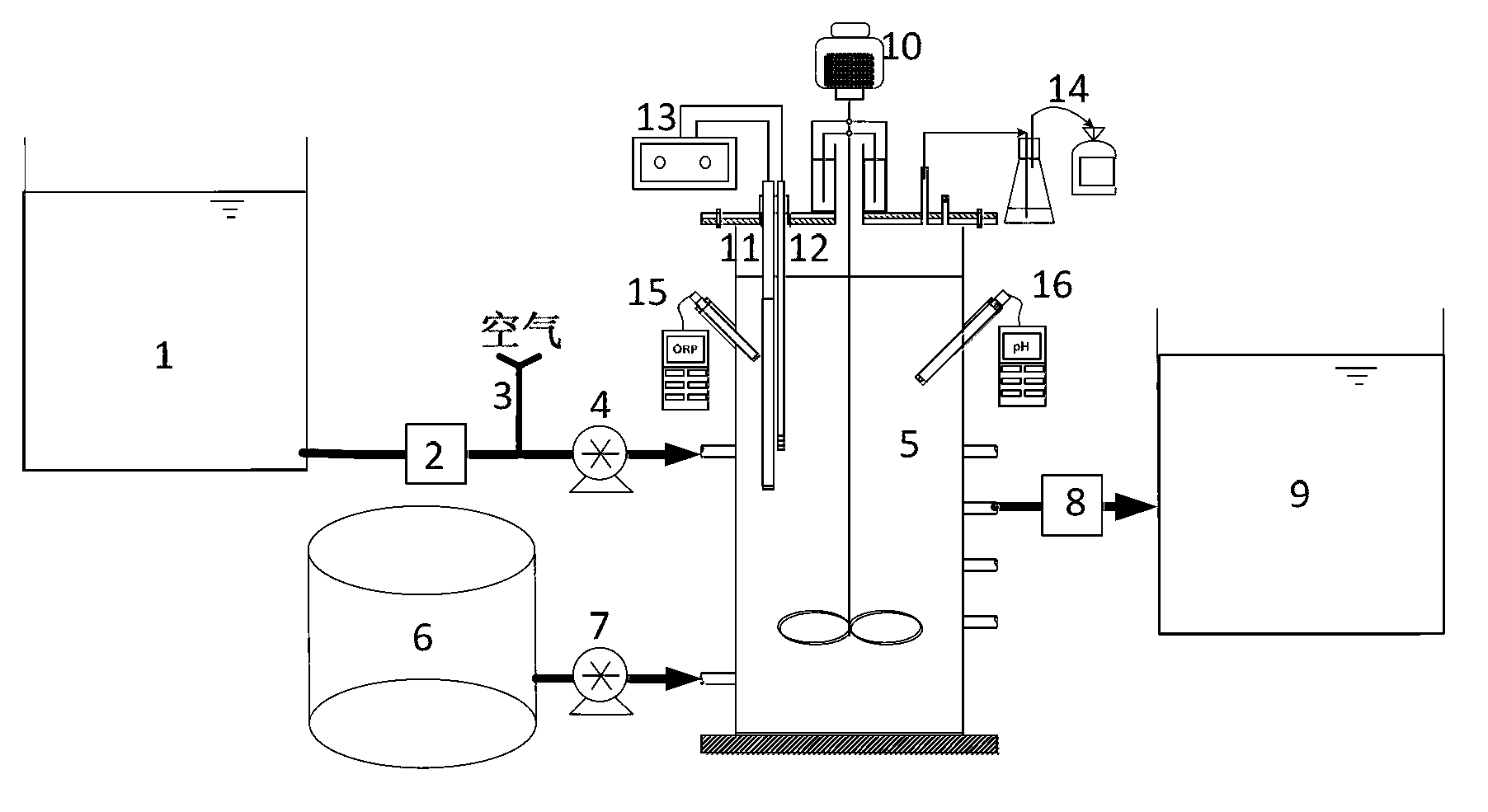

[0031] Ⅰ Mud Adding Start the mud adding pump 7, and the diluted fresh primary sludge in the sludge storage tank 6 is pumped into the sludge fermentation coupling denitrification reactor 5. Set the single mud addition volume to 0.5L, the mud addition pump 7 flow rate to 500ml / min, and the mud addition time to 5 minutes.

[0032] Ⅱ Anaerobic stirring Set the anaerobic stirring time to 9 hours. During this period the stirrer 10 continued to work.

[0033] Ⅲ Water inlet The water inlet valve 2 and the peristaltic pump 4 are turned on, and the nitrifying liquid in the water inlet tank 1 enters the sludge fermentation coupled denitrification reactor 5 through the peristaltic pump 4 . The water intake is 5 L, the flow rate of the peristaltic pump 4 is set to 500 ml / min, and the water intake time is 10 minutes.

[0034] Ⅳ Air intake During the air intake period, the intake valve 3 is opened, and the peristaltic pump 4 continues to work. The outside air is pumped into the sludge fe...

Embodiment 2

[0040] Ⅰ Mud Adding Start the mud adding pump 7, and the diluted fresh primary sludge in the sludge storage tank 6 is pumped into the sludge fermentation coupling denitrification reactor 5. Set the single mud addition volume to 0.5L, the mud addition pump 7 flow rate to 500ml / min, and the mud addition time to 5 minutes.

[0041] Ⅱ Anaerobic stirring Set the anaerobic stirring time to 20 hours. During this period the stirrer 10 continued to work.

[0042] Ⅲ Water inlet The water inlet valve 2 and the peristaltic pump 4 are turned on, and the nitrifying liquid in the water inlet tank 1 enters the sludge fermentation coupled denitrification reactor 5 through the peristaltic pump 4 . The water intake is 5L, the flow rate of the peristaltic pump 4 is set to 1L / min, and the water intake time is 5 minutes.

[0043] Ⅳ Air intake During the air intake period, the intake valve 3 is opened, and the peristaltic pump 4 continues to work. The outside air is pumped into the sludge ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com