Micro-channel-extraction-based bio-membrane reactor, and application of micro-channel-extraction-based bio-membrane reactor to butanol fermentation

A biofilm reactor and microchannel technology, applied in the application field of biological butanol fermentation, can solve the problems of low product concentration, increase separation cost, reduce biological reaction rate, etc., so as to avoid damage, enhance efficiency, and remove products. inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

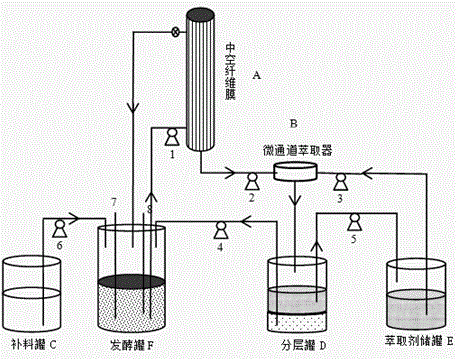

[0031] This example illustrates the composition and workflow of a microchannel extractor biofilm reactor.

[0032] The biofilm reactor based on microchannel extraction consists of a hollow fiber membrane, a microchannel extractor, a feeding tank, a layering tank, an extractant storage tank and a fermenter. The fermenter and the hollow fiber membrane are connected by a silicone tube, and the feed liquid in the fermenter is pumped into the hollow fiber membrane by a peristaltic pump, and finally flows back into the fermenter from the upper outlet. The permeate outlet of the hollow fiber membrane (the cells are trapped by the hollow fiber membrane) is connected to the inlet of the microchannel extractor, and the extraction agent storage tank is connected to the other inlet of the microchannel extractor. Under the control of the plunger pump, the precise feeding is completed, and it is fully mixed inside the extractor. The discharge port of the microchannel extractor is connec...

Embodiment 2

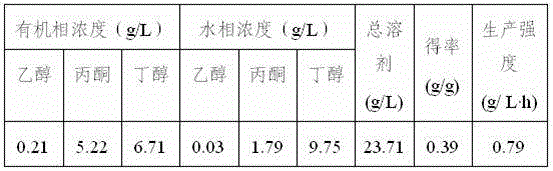

[0036] This example illustrates the application of a microchannel continuous extraction bioreactor in biobutanol fermentation.

[0037] The specific operation steps are as follows:

[0038] The strain used in this example is Clostridium beijerinckii 8052, the extraction agent is biodiesel, the flow rate ratio of the two phases of the microchannel extractor is 1:1, and the amount of extraction agent is 2L.

[0039] Strain culture:

[0040] Clostridium butanogenes Clostridium beijerinckii 8052 was inoculated into an anaerobic bottle containing 50 mL of seed medium at an inoculum volume of 5% (v / v), passed through sterile nitrogen for 1-2 minutes, anaerobically cultured at 37°C for 12 hours, and then transferred to a bottle containing 200 Secondary activation was carried out in the anaerobic bottle of mL seed culture solution, nitrogen gas was passed for 1-2 minutes, and anaerobic cultivation was carried out at 37°C for 8 hours (the strain entered the logarithmic phase). Pu...

Embodiment 3

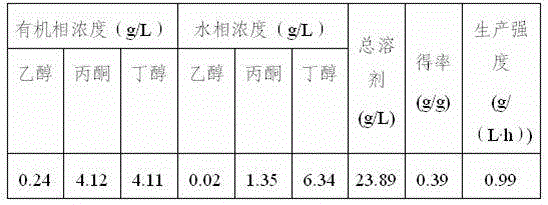

[0046] This example illustrates the application of a microchannel continuous extraction bioreactor in the production of butanol by fermentation.

[0047] The specific operation steps are as follows:

[0048] The strain used in this example is Clostridium beijerinckii 8052, the extraction agent is biodiesel. The feed flow rate ratio of the microchannel extractor is 1:2, and the extraction agent dosage is 2L.

[0049] Strain culture: Clostridium butanologenum Clostridium beijerinckii 8052 was inoculated into an anaerobic bottle containing 50mL seed medium at an inoculum volume of 5% (v / v), passed through sterile nitrogen for 1-2 minutes, anaerobically incubated at 37°C for 12 hours, and then transferred to a bottle containing 200mL seed medium. Secondary activation was carried out in the anaerobic bottle of the culture medium, nitrogen gas was passed for 1-2 minutes, and anaerobic cultivation was carried out at 37°C for 8 hours (the strain entered the logarithmic phase). P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com