Online annealing device and online annealing method for large-size optical fiber preform rod

A technology of optical fiber preform and annealing device, which is applied in manufacturing tools, glass manufacturing equipment, glass production, etc. It can solve the problems of high probability of fracture, uneven density of left and right taper parts and parallel parts, and easy cracks in the taper parts. Achieve the effects of reducing the probability of broken rods, avoiding the cracking of the cone, and uniform density of the cone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The core rod was prepared by VAD technology, and after the core rod was extended, the refractive index profile was tested, and the required amount of the outer cladding was calculated from the test results.

[0079] The mandrel after the test is docked at both ends, and the mandrel is polished after the butt joint to remove the stress caused by the butt joint. The polished mandrel with the rod is called branch rod. According to the test results, the appropriate target weight is selected, and the OVD method is used to deposit the outer cladding on the mandrel, and finally a powder rod with a target outer diameter of 150mm is obtained.

[0080] The deposition equipment is not equipped with an online annealing device. After the deposition is completed, the adhesion force of the cone of the powder rod is tested to check the force required for the powder peeling off of the cone.

[0081] Observe the condition of the cone of the preform after the sintering test to see if ther...

Embodiment 2

[0084] The deposition equipment is equipped with a fixed online annealing device, and the other processes are the same as those in Example 1.

[0085] After the deposition is complete, the cone adhesion of the powder rod is tested to verify the force required for the powder to peel off the cone.

[0086] Observe the condition of the cone of the preform after the sintering test to see if there are abnormalities such as cracking and peeling.

[0087] The deposition ends normally, the powder in the cone part does not peel off, and the preform with a normal cone part after sintering is judged as qualified, and the subsequent process is carried out.

Embodiment 3

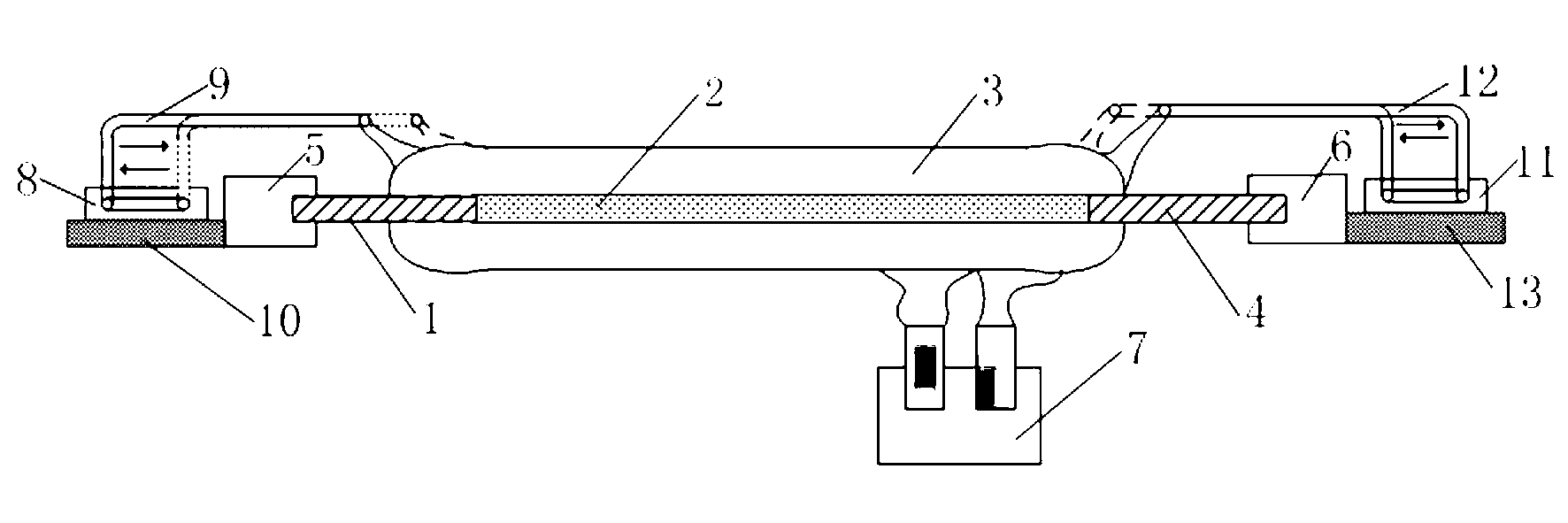

[0089] The deposition equipment is equipped with the mobile on-line annealing device of the present invention, and the other processes are the same as those in Embodiment 1.

[0090] After the deposition is complete, the cone adhesion of the powder rod is tested to verify the force required for the powder to peel off the cone.

[0091] Observe the condition of the cone of the preform after the sintering test to see if there are abnormalities such as cracking and peeling.

[0092] The deposition ends normally, the powder in the cone part does not peel off, and the preform with a normal cone part after sintering is judged as qualified, and the subsequent process is carried out.

[0093] The main technical process of the present invention will be described in detail below in conjunction with the drawings.

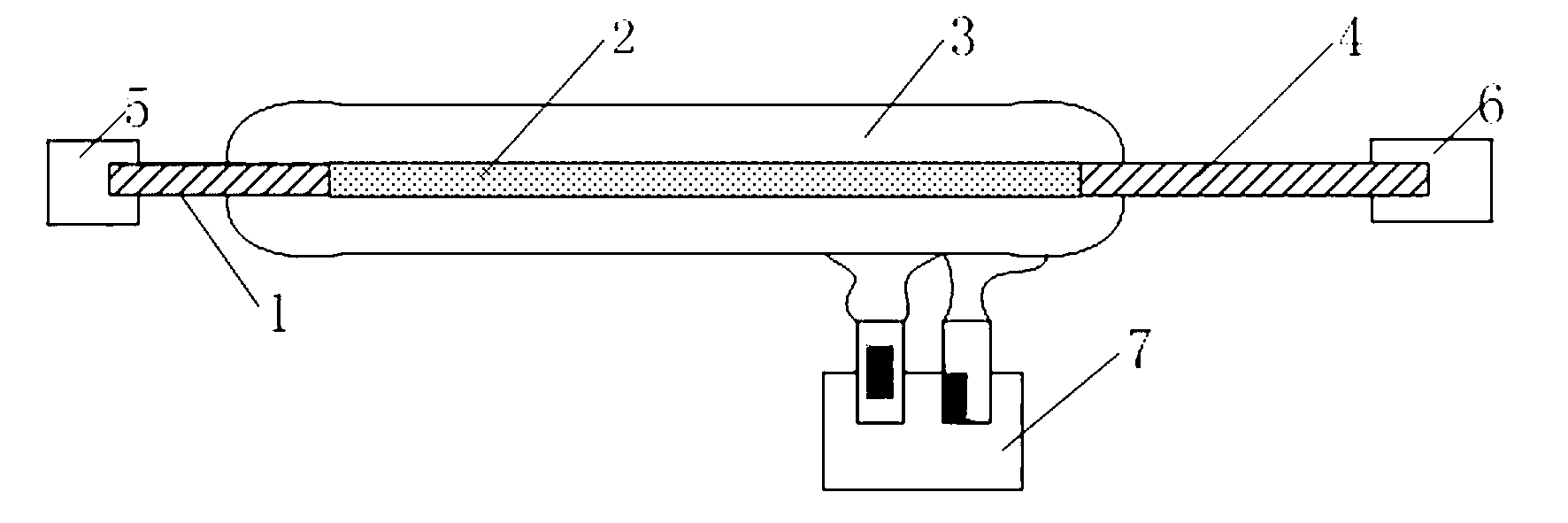

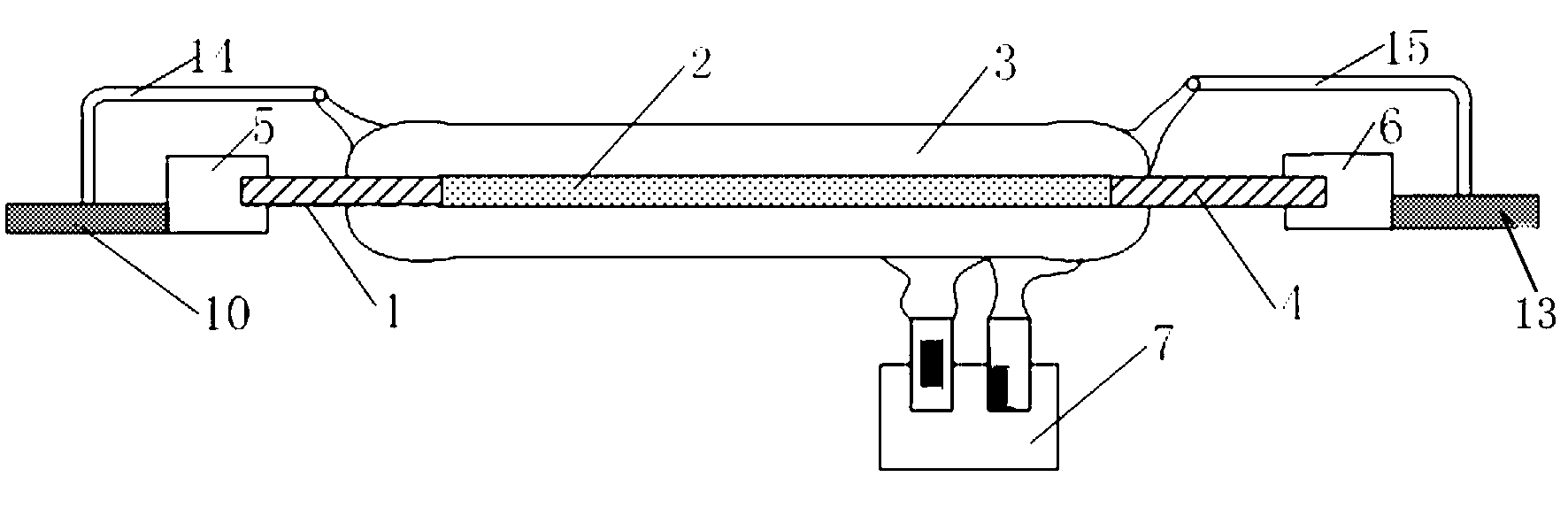

[0094] 1. The composition of the online annealing device

[0095] 1) The cylinder that controls the movement of the annealing device;

[0096] 2) Round metal blowtorch: about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com