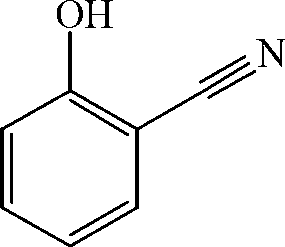

Preparation method of salicylonitrile

A technology of o-hydroxybenzonitrile and o-hydroxybenzamide, which is applied in the dehydration preparation of carboxylic acid amides, organic chemistry, etc., can solve problems such as being unsuitable for large-scale production, complicated process, difficult to remove, etc. Simple and safe, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

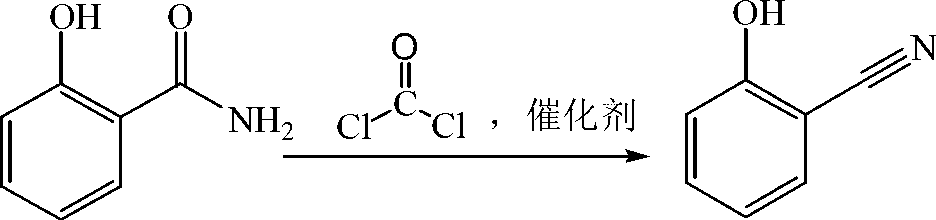

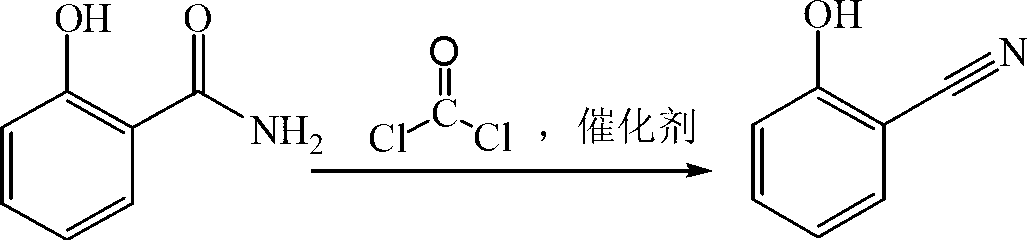

Method used

Image

Examples

Embodiment 1

[0014] 13.7g (0.1mol) o-hydroxybenzamide, 41.1g (0.39mol) xylene, 0.014g (1.6×10 -4 mol) dioxane was added to a 100mL three-necked flask with a stirring and reflux tube, heated to reflux, and 11.9g (0.12mol) phosgene was introduced within 2hr.

[0015] After 0.5hr of heat preservation, 21g of xylene was evaporated from the reaction solution, the concentrated solution was stirred and crystallized in an ice-water bath, and 11.8g of o-hydroxybenzonitrile was obtained by filtration, with a content of 98.3% (liquid chromatography external standard method, the same below), and the yield 97.5%.

Embodiment 2

[0017] 13.7g (0.1mol) o-hydroxybenzamide, 68.5g (0.65mol) xylene, 0.041g (4.7×10 -4 mol) dioxane was added to a 100mL three-necked flask with a stirring and reflux tube, heated to reflux, and 11.9g (0.12mol) phosgene was introduced within 3hr.

[0018] After 0.5 hr of heat preservation, 34 g of xylene was evaporated from the reaction solution, the concentrated solution was stirred and crystallized in an ice-water bath, and 11.6 g of o-hydroxybenzonitrile was obtained by filtration, with a content of 98.9% and a yield of 96.4%.

Embodiment 3

[0020] 13.7g (0.1mol) o-hydroxybenzamide, 108g (1.02mol) xylene, 0.068g (7.7×10 -4 mol) dioxane was added to a 100mL three-necked flask with a stirring and reflux tube, heated to reflux, and 11.9g (0.12mol) phosgene was introduced within 4hr.

[0021] After 0.5 hr of heat preservation, 55 g of xylene was evaporated from the reaction solution, the concentrated solution was stirred and crystallized in an ice-water bath, and 11.5 g of o-hydroxybenzonitrile was obtained by filtration, with a content of 99.2% and a yield of 95.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com