The method of styrene epoxidation reaction

A technology of epoxidation reaction and styrene, which is applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of poor catalyst stability and achieve the effects of good stability, low cost and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh 10 millimoles of o-aminophenol, put it into a round-bottomed flask (50 milliliters) containing 20 milliliters of absolute ethanol, heat and stir at 50° C., add 10 millimoles of 2-acetylpyridine after the o-aminophenol is completely dissolved, and stir for 1 After 6 days, the light yellow polyhedral crystals were separated by suction filtration and washed with a small amount of ethanol to obtain 2-acetylpyridine o-aminophenol Schiff base complex.

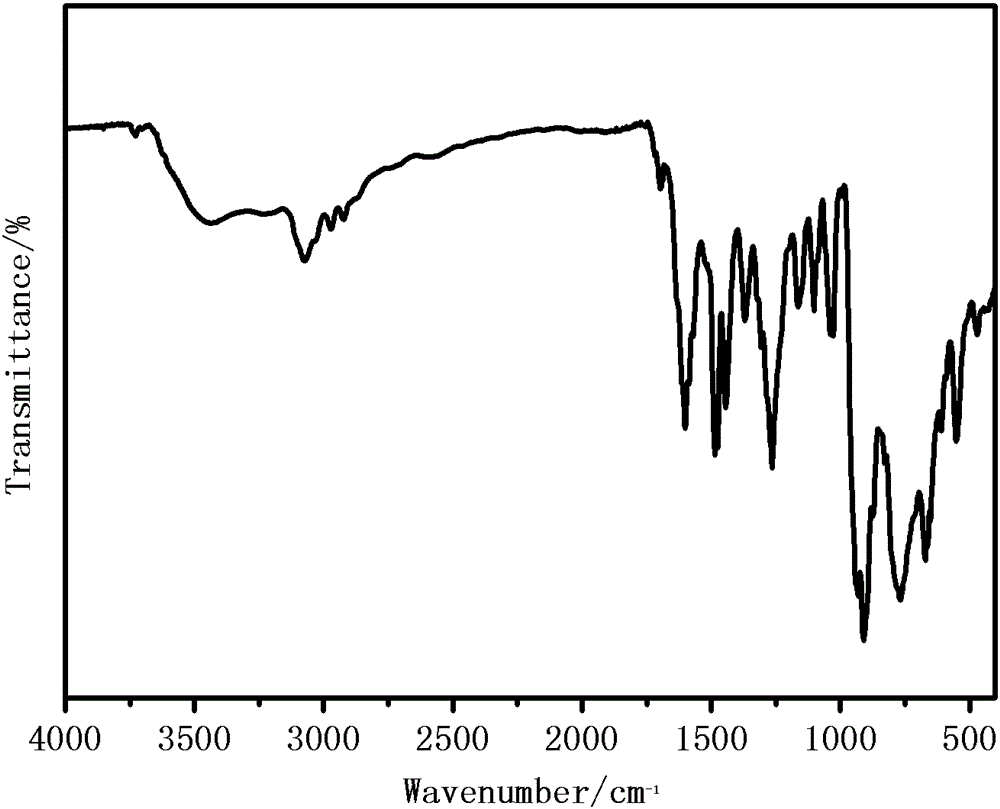

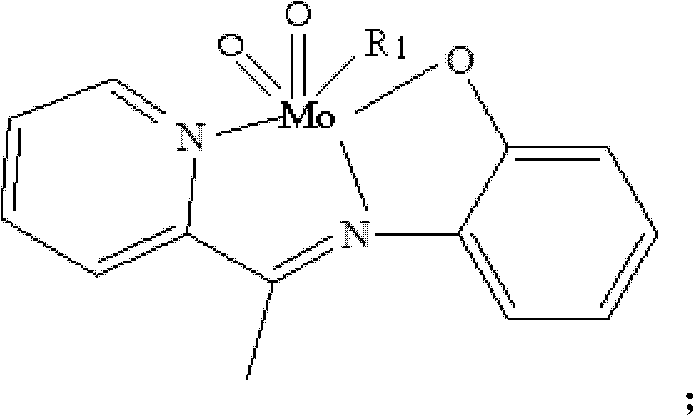

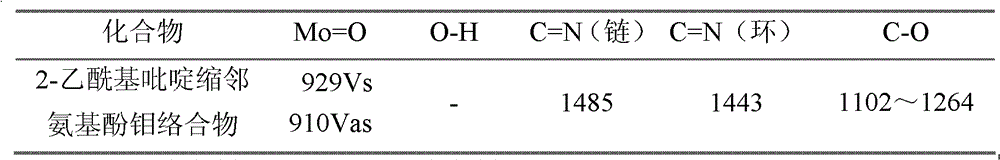

[0021] Weigh 5mmol of 2-acetylpyridine-o-aminophenol, put it into a round-bottomed flask (50ml) containing 15ml of absolute ethanol, heat and stir at 75°C, and add 5mmol of acetylacetone after the 2-acetylpyridine-o-aminophenol is completely dissolved Molybdenum, stirred brown powder to precipitate, continue to heat and stir for 2 hours, then cool and suction filter, wash with ethanol and dry in vacuum at 40°C to obtain a brown powder product, its structural formula is as follows, and its infrared analysis spectrum is sho...

Embodiment 2

[0024] Weigh 10 mmol of o-aminophenol, put it into a round-bottomed flask (50 ml) containing 20 ml of pyridine, heat and stir at 50°C, add 10 mmol of 2-acetylpyridine after the o-aminophenol is completely dissolved, and stir for 1 hour After standing for 6 days, the light yellow polyhedral crystals were separated by suction filtration and washed with a small amount of ethanol to obtain 2-acetylpyridine o-aminophenol Schiff base complex.

[0025] Weigh 5mmol of 2-acetylpyridine-o-aminophenol, put it into a round-bottomed flask (50ml) containing 15ml of pyridine, heat and stir at 75°C, and add 5mmol of molybdenum acetylacetonate after the 2-acetylpyridine-o-aminophenol is completely dissolved. Stir brown powder to precipitate, continue to heat and stir for 2 hours, then cool and suction filter, wash with pyridine and dry in vacuum at 40°C to obtain the product. Its structural formula is as follows, and its infrared analysis spectrum is consistent with figure 1 resemblance.

[0...

Embodiment 3

[0028] Take 2.5mmol (0.29ml) of styrene, 5mmol (0.72ml) of tert-butyl hydroperoxide (TBHP), 6ml of benzene as solvent, and 0.025mmol of catalyst, put them into a 25ml one-necked flask, stir in an oil bath at 80°C, condense and reflux 9h. The molar ratio of styrene to catalyst was 100:1.

[0029] Reaction result: the conversion rate of styrene is 69.35%, and the selectivity of styrene oxide is 80.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com