Quick high-efficiency reverse carbonation tank

A full-filling and high-efficiency technology, which is applied in the purification of alkaline earth compounds, sucrose production, sugar production, etc., can solve the problems of difficult removal, low cleaning efficiency, and many non-sugar impurities, so as to achieve the goal of not easily leaking out of the tank, short residence time, The effect of low fill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

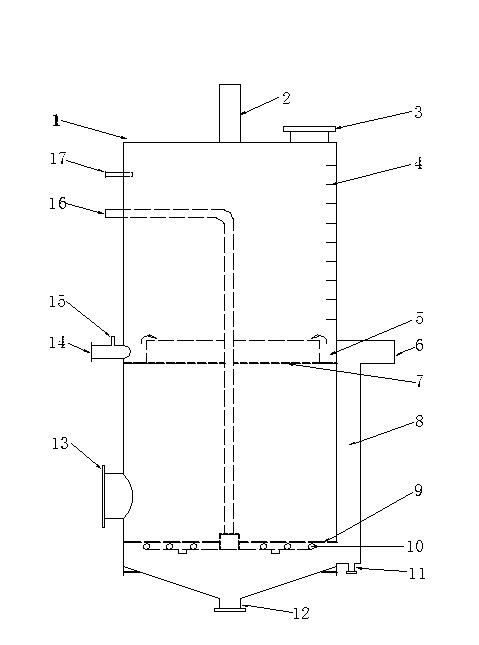

[0014] 1. Installation location and connection relationship

[0015] The filling tank 1 of the present invention is cylindrical at the top and conical at the bottom; the diffuser pipe 2 is installed on the top of the filling tank 1 and communicates with the filling tank; the upper manhole 3 is located at the top edge of the filling tank; The lower part of the manhole 3 is welded with the inner wall of the full tank; the upper distribution plate 7 is located in the middle of the cylinder; the juice outlet 8 is located outside the full tank, the lower part communicates with the conical bottom of the full tank, and the upper part communicates with the full tank. The juice filling outlet pipe is connected; the cloth ring groove 5 is located between the upper distribution plate 7 and the inner wall of the full filling tank, and is welded on the inner wall of the full filling tank; the full juice outlet 6 is located at the same horizontal position of the cloth ring groove 5, connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com