Method for smelting iron-based nanocrystalline master alloy

An iron-based nanocrystal and master alloy technology, applied in the field of master alloy smelting, can solve the problems of high impurity content of master alloy, burning loss of beneficial elements, large damage to furnace lining, etc., and achieves good spray belt toughness, cost saving, and improvement of smelting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

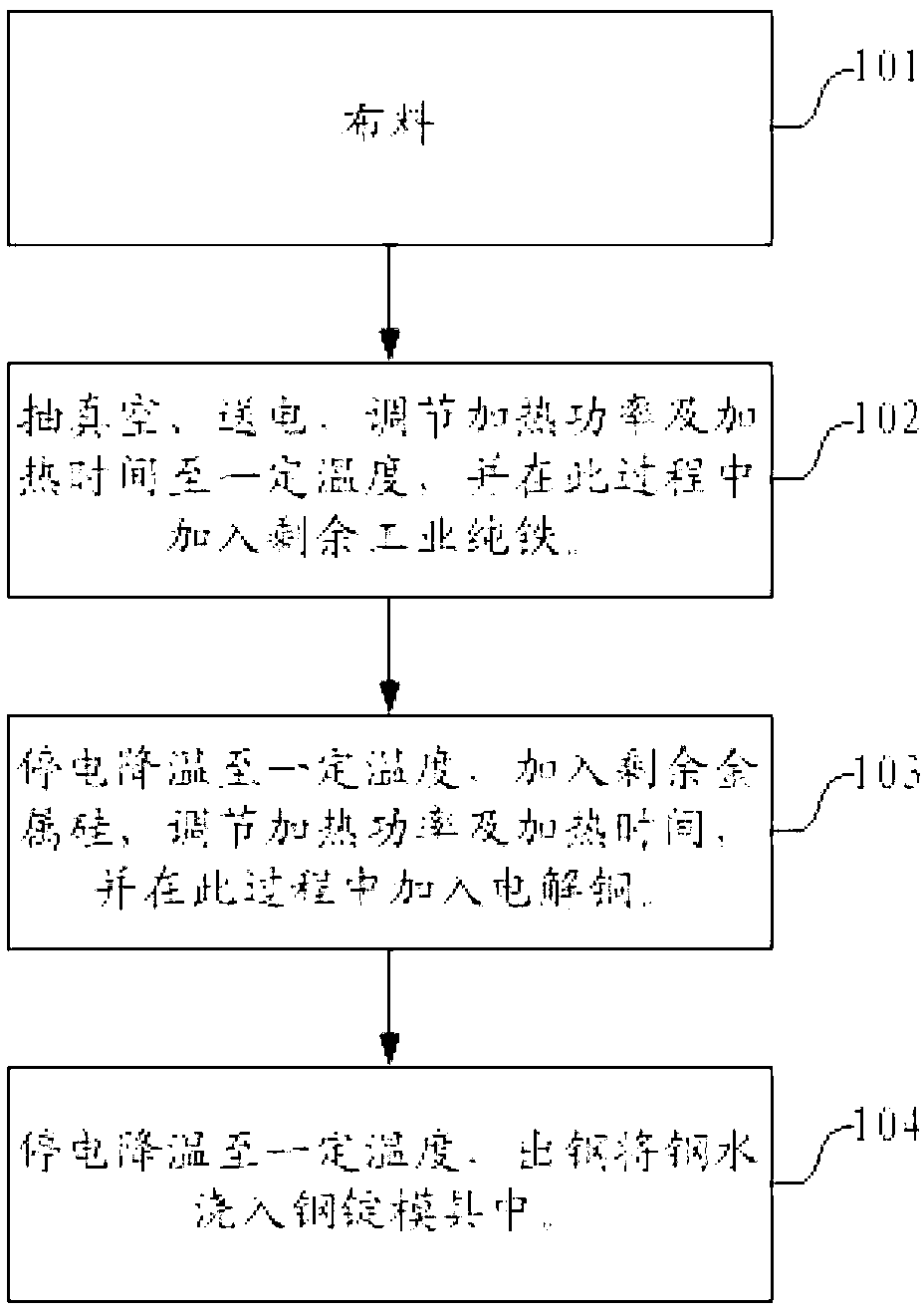

[0010] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0011] figure 1 It is a flowchart of a method for smelting a nanocrystalline master alloy according to an embodiment of the present invention.

[0012] In step 101, 3-5kg of metallic silicon is spread on the bottom of the furnace, a piece of industrial pure iron is vertically placed in the furnace and touches the bottom of the furnace, and then 6-7 pieces of industrial pure iron are vertically placed on the bottom of the furnace. Metal silicon, and ensure that there is an equal gap between the industrial pure irons, then sprinkle half of the raw material ferroboron into the lower half of the gap in the furnace, sprinkle ferroniobium into the middle gap in the furnace, and sprinkle the remaining ferroboron into the upper part of the furnace half void.

[0013] In step 102, after the material distribution in step 101 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com