Directly-connected headstock gear

A hoist, direct-connected technology, applied in the field of hoists, can solve the problems of complex structure of hoists and long power transmission process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

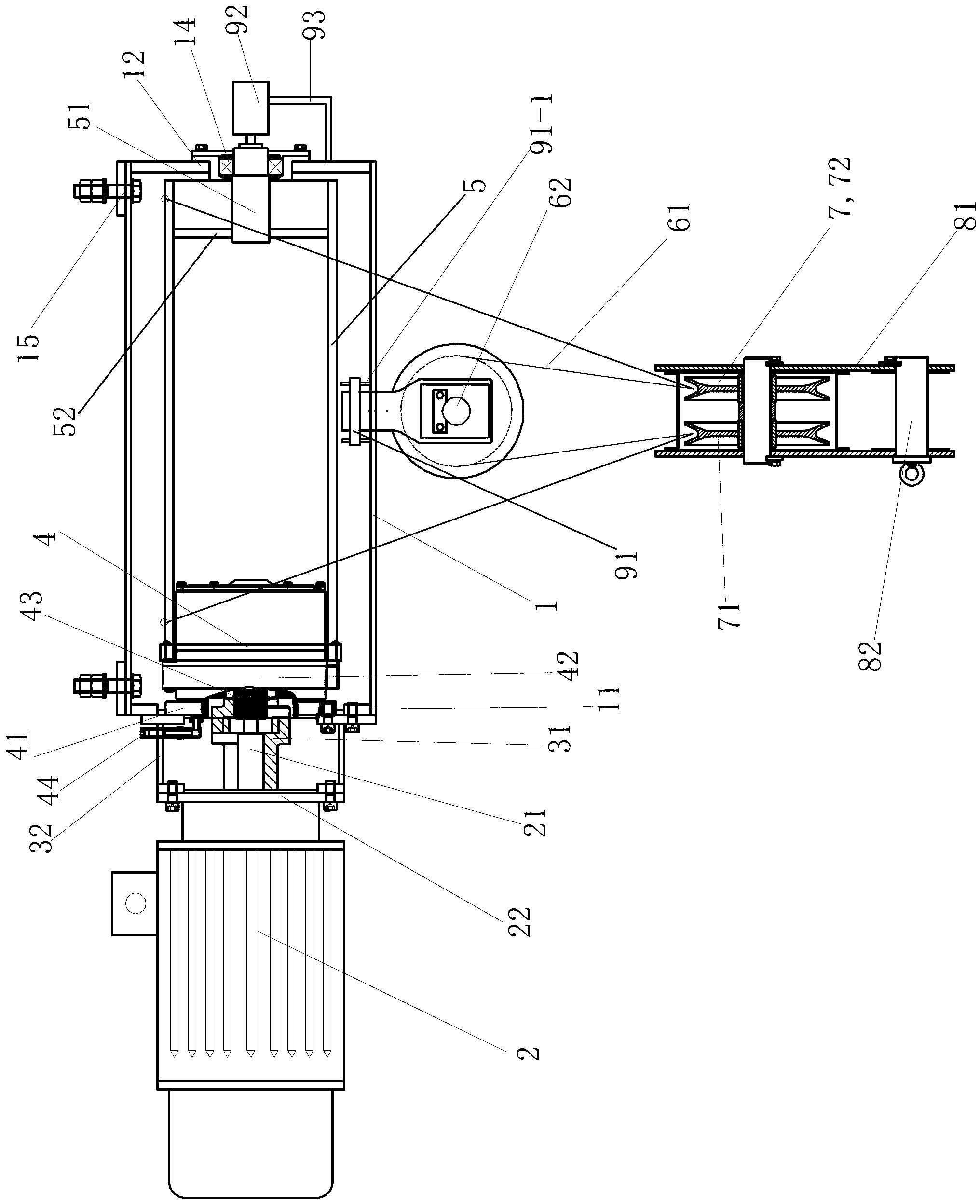

[0071] (Example 1, direct-connected single suspension point suspension hoist)

[0072] See figure 1 , the direct-connected hoist of this embodiment is a direct-connected single-suspension-point hoist, specifically a direct-connected single-suspended-point hoist.

[0073] The direct-coupled single-suspension suspension hoist of this embodiment includes a frame 1, a motor 2, a coupling 31, a connecting seat 32, a reducer 4, a wire rope reel 5, a wire rope 61, a balance pulley device 62, and a movable pulley block 7. Spreader 8, lifting capacity limiter 91 and height indicator device 92; motor 2 is fixed on frame 1 through connection seat 32, motor 2 is connected with input shaft of reducer 4 through coupling 31, reducer 4 One end of it is fixed on the frame 1, and the other end is positioned at the inside of the wire rope reel 5. The rotating shaft of motor 2, shaft coupling 31, input shaft and output end of speed reducer 4 and wire rope reel 5 are coaxially arranged.

[0074...

Embodiment 2

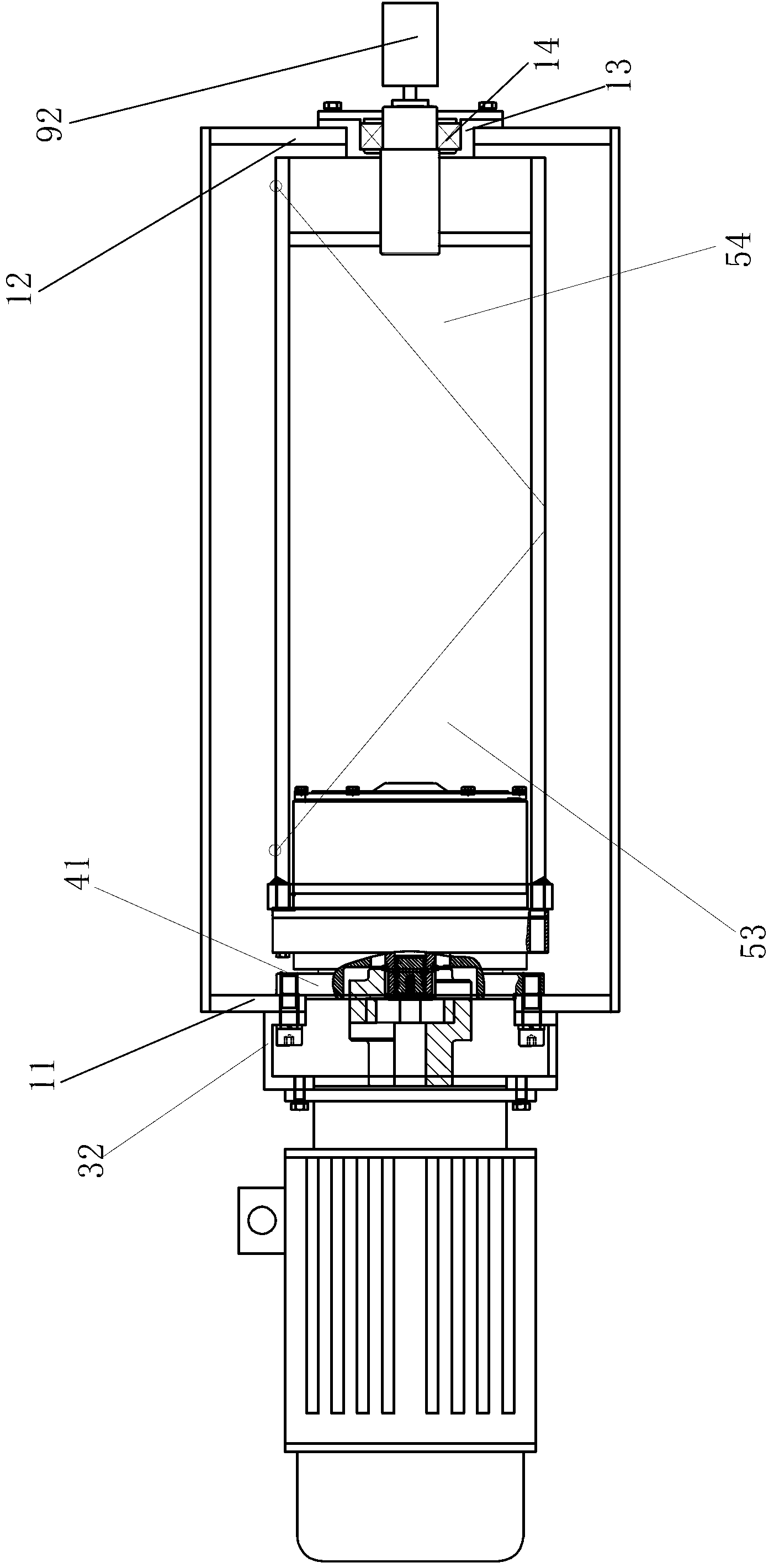

[0095] (Example 2, direct-connected single suspension point suspension hoist)

[0096] See figure 2 , the rest of the direct-coupled single-point hoist hoist of this embodiment is the same as that of Embodiment 1, the difference is that: the center of the right connecting plate of the connecting seat 32 is provided with a through hole, and the periphery of the through hole is provided with a circle of mounting holes; The edge of the left end face of the right connecting plate is welded and fixed to the right end face of the connecting ring, so that the left end face of the right connecting plate is located inside the connecting ring.

[0097] The right connecting plate of the connecting seat 32 is located in the center of the left end face of the left end plate 11 of the frame 1, and is in contact with the left end face of the left end plate 11 of the frame 1 from left to right; the fixed flange 41 of the reducer 4 is located at The center of the right side end face of left ...

Embodiment 3

[0098] (Embodiment 3, Direct-connected single hoisting point bottom mounted hoist)

[0099] See Figure 4 , the direct-connected single-suspension hoist of this embodiment is a direct-connected single-suspension bottom-mounted hoist, and the rest of the hoist is the same as that of Embodiment 1, except that the installation hole of the frame 1 is set at the lower connection On the frame, the lower connecting frame of the frame 1 is provided with a lower mounting hole 16, and the frame 1 can be fixed on the mounting platform of the dam through the lower mounting hole 16 during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com