[0002]At present, the tower cranes produced by all tower crane manufacturers in China are not equipped with tower crane foundations when they leave the factory. The main reason is that the overall fixed foundation is too heavy and not suitable for Transportation, split-type combined foundation technology is immature, not as safe as fixed cast-in-place foundation, manufacturers always follow the tower crane with a fixed foundation pouring drawing, and the buyer and user use on-site cast-in-place concrete

prefabrication, on-site

prefabrication Although the foundations are safe and reliable, they are more than tens of tons and are not suitable for hoisting, transportation and reuse. In the future, each time the tower crane is installed and disassembled, the foundation needs to be prefabricated. The production process consumes manpower and

material resources.

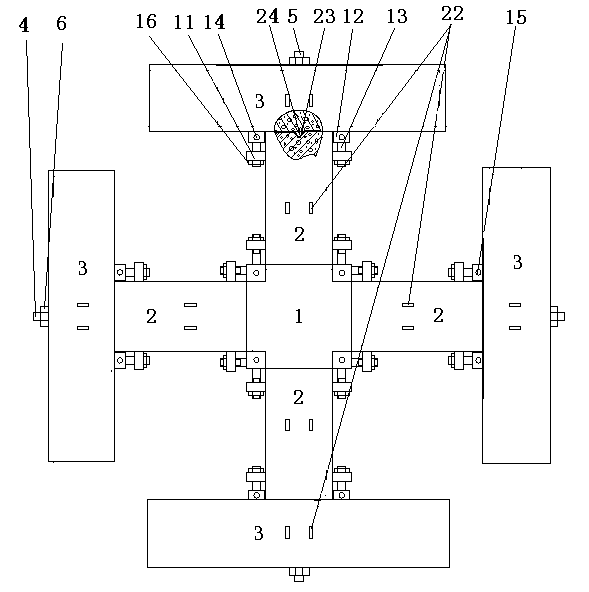

In order to solve the above problems, in recent years, many people have designed and produced several combined foundations, which have been tried in some areas. The combined foundation has been popularized and used in some areas because of its characteristics of being disassembled and reused, and convenient for short-distance transportation. 具有代表性的有赵正义提交的的申请号(98101471.2、9810147.4、200610002190.6、200610067145.9、201110146469.2、201120183188.x)和丛卫民提交的申请号(200420080405.2、200510038753.2、201110129155.1)以上在不断的创新和改进中,逐渐 It is recognized by people. Their main

advantage is that the foundation with an overall weight of more than 40 tons can be disassembled and divided into several pieces, which are suitable for short-distance hoisting and transportation to another place for combined installation and reuse, avoiding the great waste of one-time foundations. In contrast, it saves a certain amount of concrete and steel reinforcement resources, but its technology still has deficiencies, and there are many safety hazards. In general, its structure has the following problems: (1) The structure of single

bolt connection is unreasonable, easy to

Corrosion is not easy to replace, the pre-tightening force of the connection cannot be achieved, and the single connection method of steel strands is not safe enough, there is no insurance barrier, the steel strands will relax under long-term working conditions, and the anchors tend to

spin out when they are reused (2) Due to the excessive pursuit of reducing the ground

bearing capacity of the modeling structure, the

shear force and

bending moment carried by the end surface of the foundation are ignored, the

total thickness of the structure and the main force-bearing cross-sectional area of the upper end surface are too small, And the weight of the structure is too light, because the weight of the foundation is directly proportional to the overturning force, which requires a large amount of

ballast, bulk materials or buried disposal, which increases the cost of use; (3) The structure of the shear parts is unreasonable, and The pre-embedded steel bars are welded together, and the weld joints are only pre-embedded in concrete at a depth of 1cm. The shear-resistant structural parts are too small and too simple. It is found that it is not easy to repair, has low reliability, and has potential safety hazards; (4) There are many reserved bolt holes on the main force-bearing structure, which reduces the load-bearing performance and service life of the structure; (5) Because of its special structural shape, A large number of special molds are required in the production process, which is not suitable for the needs of scattered small groups of customers. The small group of customers with tower cranes in China is widely distributed, so that the total proportion is quite large, which affects the

penetration rate; (6) Structure The shape of the design is not convenient enough for transportation, it takes up too much space in the compartment, and it takes up too much space for storage. The basic weight of the whole

machine is more than 20 to 30 tons, and the cost of long-distance supply is high or even several times higher than the cost price; (7 ) There are weaknesses in the structural modeling, and the expansion angles and corners of the foundation are easy to be damaged during repeated disassembly and transportation, which seriously affects the number of uses; (8) Since the horizontal error of the standard section base is required to be within 2mm when installing the tower crane, This means that the tower crane must have extremely strict requirements on its foundation, and there must be no mistakes, and the horizontal error may exceed 2mm. There may be safety accidents. From the perspective of safety, a comprehensive analysis of the structure of the prefabricated and assembled tower crane foundation of the existing technology has certain hidden safety hazards. The service life cannot be as suitable for long-term strategies as railways and highway bridges, which affects Return on investment, affecting resource savings

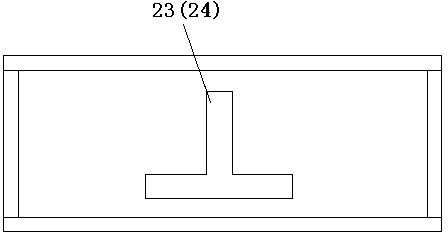

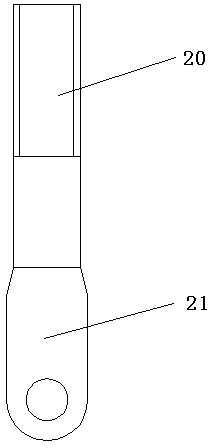

[0003] On July 20, 2011, the applicant applied to the State Administration of China for a utility model patent for a series-connected tower crane foundation, which has a main concrete foundation, The center line of the main concrete foundation is connected in series with the transition foundation unit and the end foundation unit. The adjacent contact surfaces of the main concrete foundation, the transition foundation unit and the end foundation unit are respectively provided with positioning devices. The main concrete foundation, the transition foundation unit and the The end foundation unit is positioned and connected by the positioning device, the end foundation unit, the transition foundation unit and the main concrete foundation are horizontally provided with zipper reserved holes, and the end foundation unit, the transition foundation unit and the main concrete foundation pass through the zipper pre-set The reserved holes are fixedly connected. The end foundation unit and the transition foundation unit are respectively provided with reserved holes for anchor bolts. It is connected with the bottom beam pressure plate of the tower crane. The disadvantages are: 1. During repeated disassembly and transportation, the corners and positioning devices of the foundation are easy to be cracked and damaged, which seriously affects the stability of the tower crane. 2. The foundation at the end There are reserved holes for anchor bolts on the unit and the transitional basic unit, which greatly reduces the

shear force and

bearing capacity of the basic unit, which may easily cause the basic unit to break and cause accidents, and the replacement of the anchor bolts is time-consuming and laborious

Login to View More

Login to View More  Login to View More

Login to View More