Treatment vehicle and treating method for sucking sludge in city pipe network

A technology for treating trucks and sludge, applied in separation methods, chemical instruments and methods, and filtration circuits, etc., can solve the problems of high sludge transportation costs, complex sediment components, secondary environmental pollution, etc., and achieve cleaning efficiency High, avoid secondary pollution, low labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

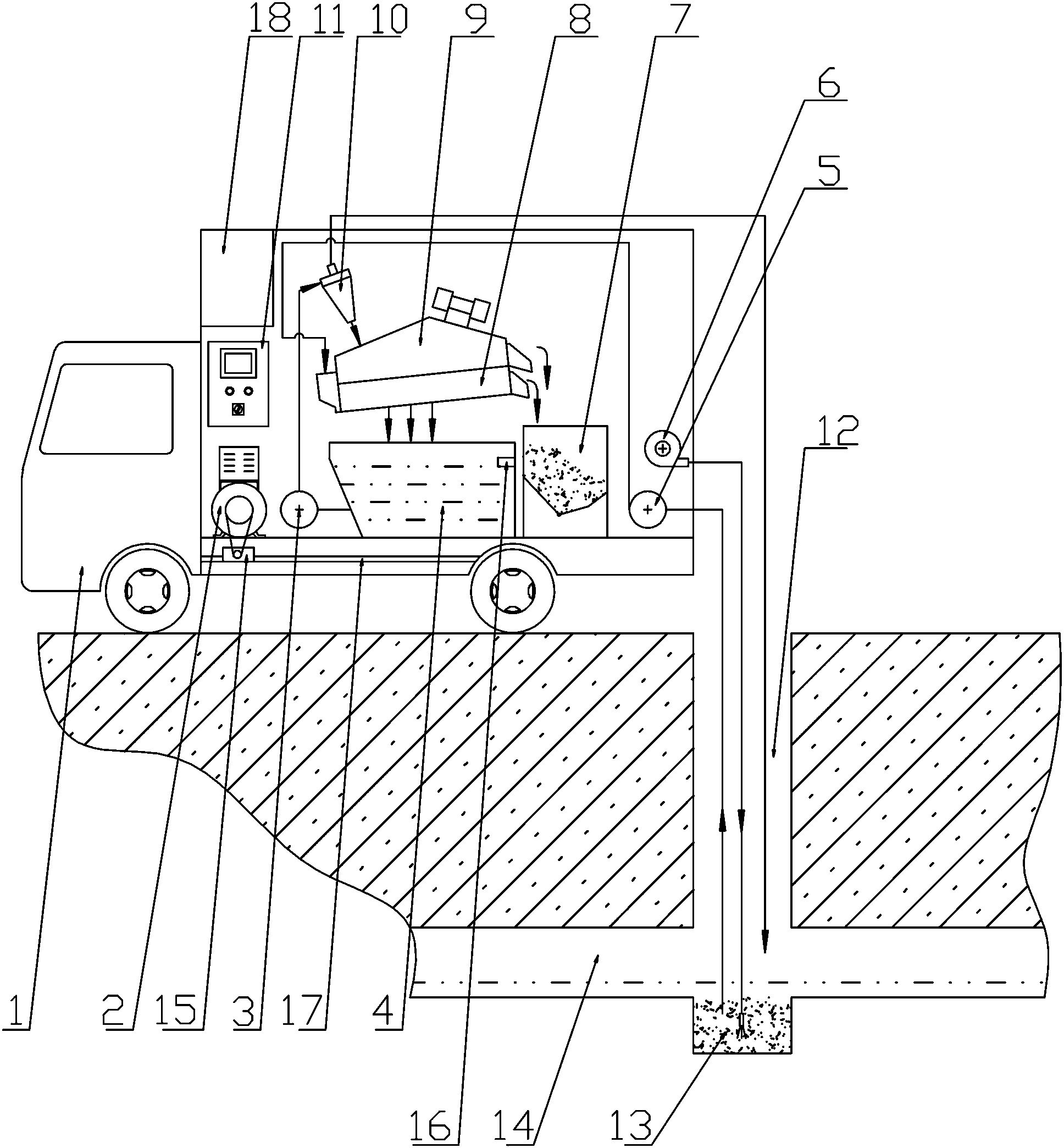

[0042] Such as figure 1 Among them, an urban pipe network sludge suction treatment vehicle includes a vehicle 1, which is provided with a generator 2 for supplying power to electrical components, and the generator 2 is electrically connected to each electrical component through a control cabinet 11. The control cabinet 11 adopts relay or PLC control to supply power to the electrical components. The PLC control cabinet 11 implements program control operation for all process equipment to realize automatic operation. For example, the vibration motors of the slurry pump 3, the upper sieve 8 and the lower sieve 9, the sewage suction pump 5, etc.

[0043] The vehicle 1 is provided with a silt box 4, and the top of the silt box 4 is provided with a lower sieve 9 and an upper sieve 8 in turn, and the sieves of the lower sieve 9 and the upper sieve 8 are connected with the slag hopper 7; the slag hopper 7 is used to store processed The slag material has a moisture content of ≤30%, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com