Variable diameter stabilizer and its system

A stabilizer and shell technology, which is applied in the field of variable diameter stabilizers and their systems, can solve the problems of recording mud pressure, the impact of drilling work, and the damage of variable diameter stabilizers, and achieves the effect of reducing pressure and ensuring safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

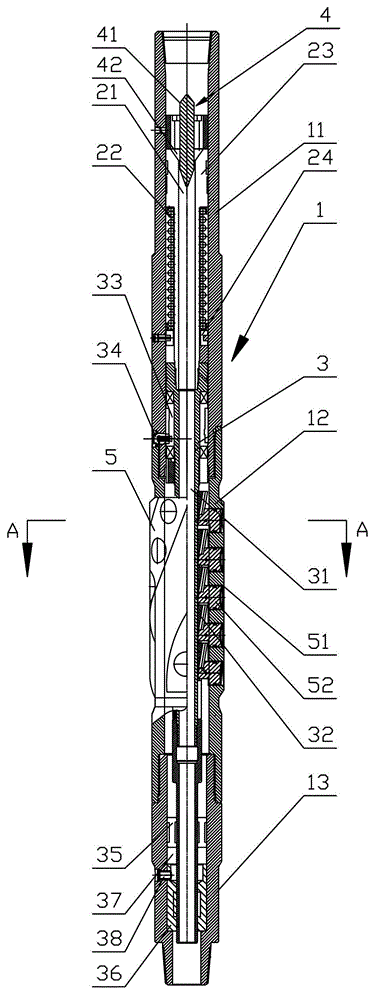

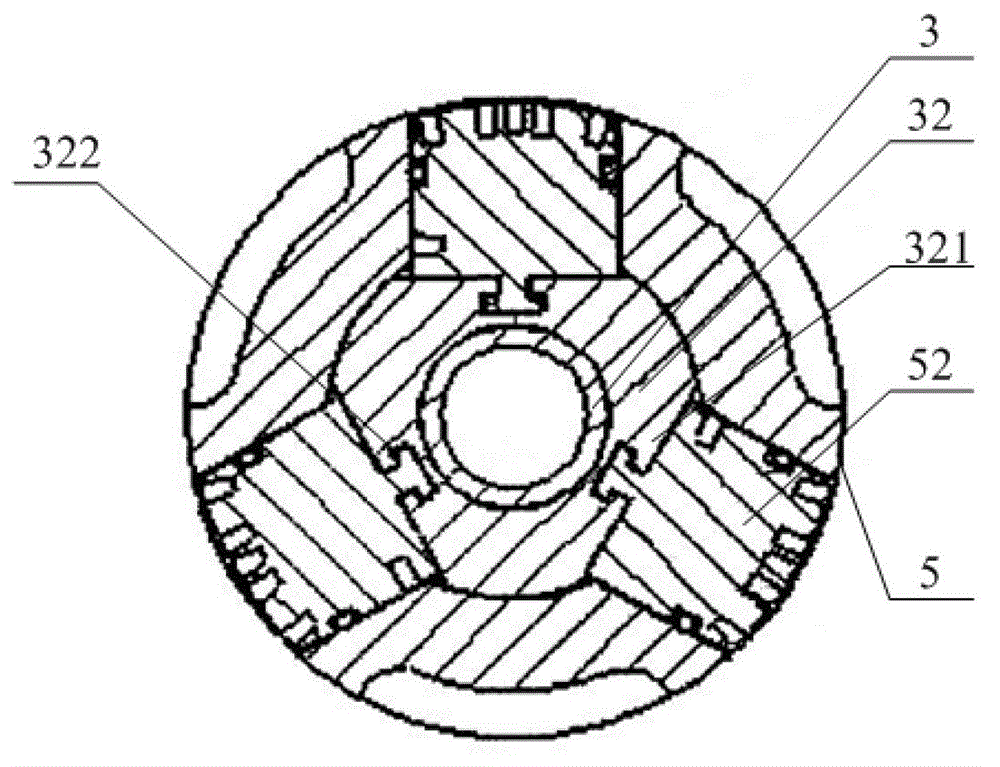

[0045] Such as figure 1 with figure 2 As shown, the variable diameter stabilizer provided in this embodiment includes a casing 1, an upper mandrel 2 and a lower mandrel 3, and an upper high-pressure mud chamber 21 is formed inside the upper mandrel 2 along the axial direction of the casing 1, The inside of the lower mandrel 3 is formed with a lower high-pressure mud chamber 31 along the axial direction of the shell 1, the lower end of the upper mandrel 2 is connected and fixed to the upper end of the lower mandrel 3, and the upper high-pressure mud chamber 21 communicates with the lower high-pressure mud chamber 31 ; Also includes a mud pressure changing device 4, the mud pressure changing device 4 is composed of a mushroom head assembly 41 and a central hole 42, the central hole 42 is arranged on the top of the upper mandrel 2, and the diameter of the upper end of the central hole 42 is greater than the diameter of the lower end, the center The hole 42 communicates with the...

Embodiment 2

[0075] Due to the variable diameter stabilizer, when judging its working state, it is usually to observe the change of the degree of the pressure gauge on the mud pump. However, since the variable-diameter stabilizer usually operates several thousand meters below the ground, the pressure in the variable-diameter stabilizer will attenuate to a large extent when it is transmitted to the ground. For example, when the pressure of the mud changes around 2 MPa, the pressure signal is attenuated in the upload and the strong vibration of the drill floor will make it impossible for the ground operator to accurately read the pressure change of the pressure gauge. Therefore, in order to directly observe the change of the pressure gauge degree on the ground, the mud pump is often required to increase the pressure of mud injection, so as to offset the influence caused by the pressure attenuation. As a result, the mud pressure in the variable diameter stabilizer often exceeds the normal dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com