Comprehensive method of drilling, permeability increasing, repairing and gas-driven displacing of drill hole underground coal mine

A comprehensive method and technology for coal mines, applied in drill pipe, drill pipe, mining equipment, etc., can solve the problems affecting mine outburst elimination plan and production deployment, no large-scale promotion and application, difficult to control equipment volume, etc. The effect of gas extraction efficiency, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

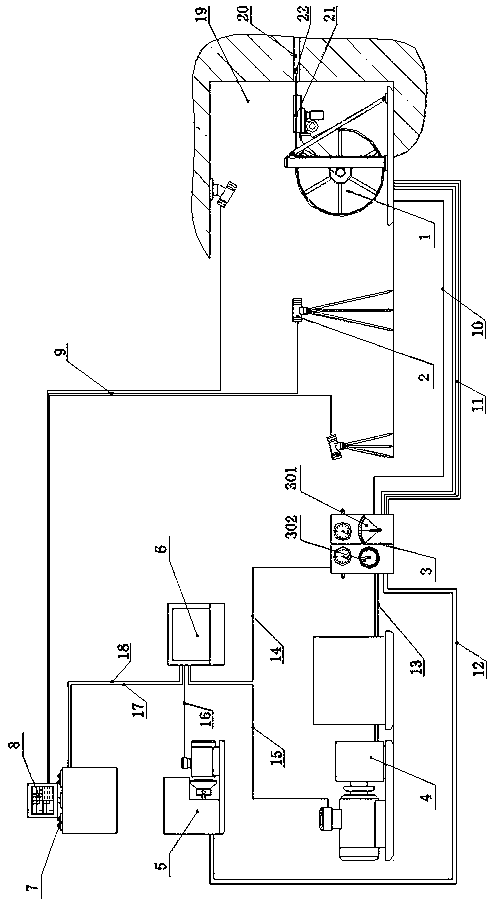

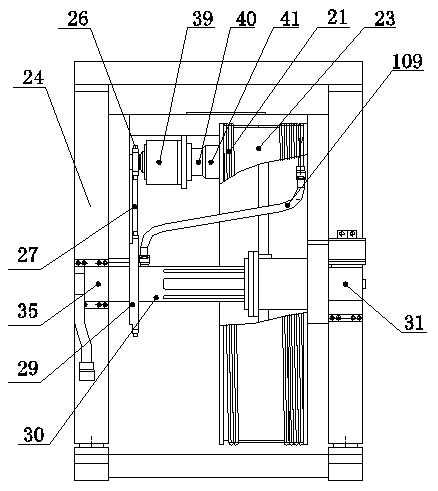

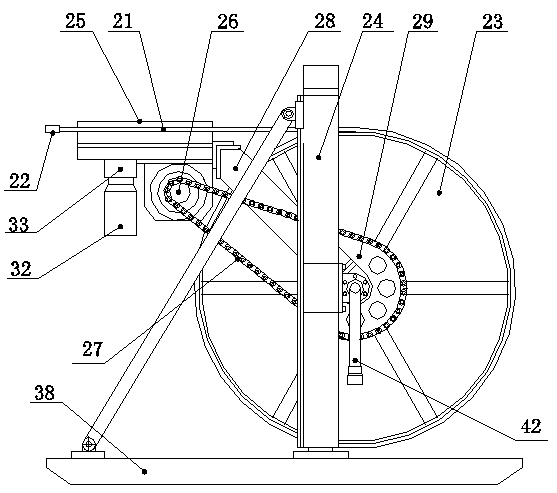

[0062] Such as figure 1 As shown, the mining hydraulic operation machine includes a main engine 1, an executive platform 3, a clean water pump station 4, a hydraulic pump station 5 and a switch cabinet 6, the executive platform 3 passes through a power cable 14, and the clean water pump station 4 passes through a power cable 15, and the hydraulic pump station 5 are respectively electrically connected to the switch cabinet 6 through power cables 16, and the clean water pumping station 4 uses high-pressure water as the medium, and under necessary conditions, ceramics, polyoxymethylene, etc. can be used as proppants. A flexible steel pipe remote controller 301 and a high-pressure water remote controller 302 are installed in the execution platform 3. The host 1 is connected to the flexible steel pipe remote controller 301 through four oil pipes 11, and connected to the high-pressure water remote controller through a water pipe 10. 302 connected, on the other side of the execution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com