Heat exchange system

A heat exchange system and vacuum heat insulation technology, applied in the field of heat exchange systems, can solve the problems of reduced service life of refrigeration equipment, decreased energy efficiency of refrigeration equipment, frequent start and stop of refrigeration equipment, etc., to reduce insulation costs, reduce temperature differences, and improve storage capacity. the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

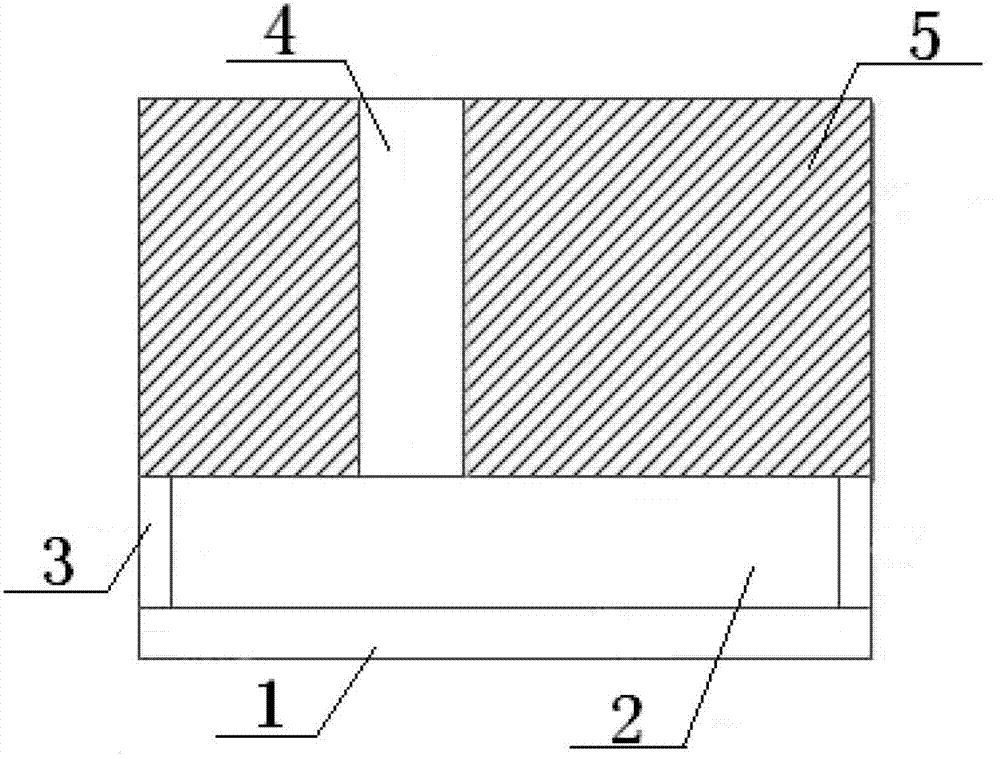

[0022] Embodiment 1 of the present invention: as figure 1 As shown, a heat exchange system includes a refrigeration layer 1, a cold storage layer 2, a cooling channel 4 and a cooled device 5, the refrigeration layer 1 and the cold storage layer 2 are arranged below the cooled device 5, and the cold storage layer 2 is set Above the cooling layer 1 , an insulating layer 3 is provided on the outside of the cold storage layer 2 .

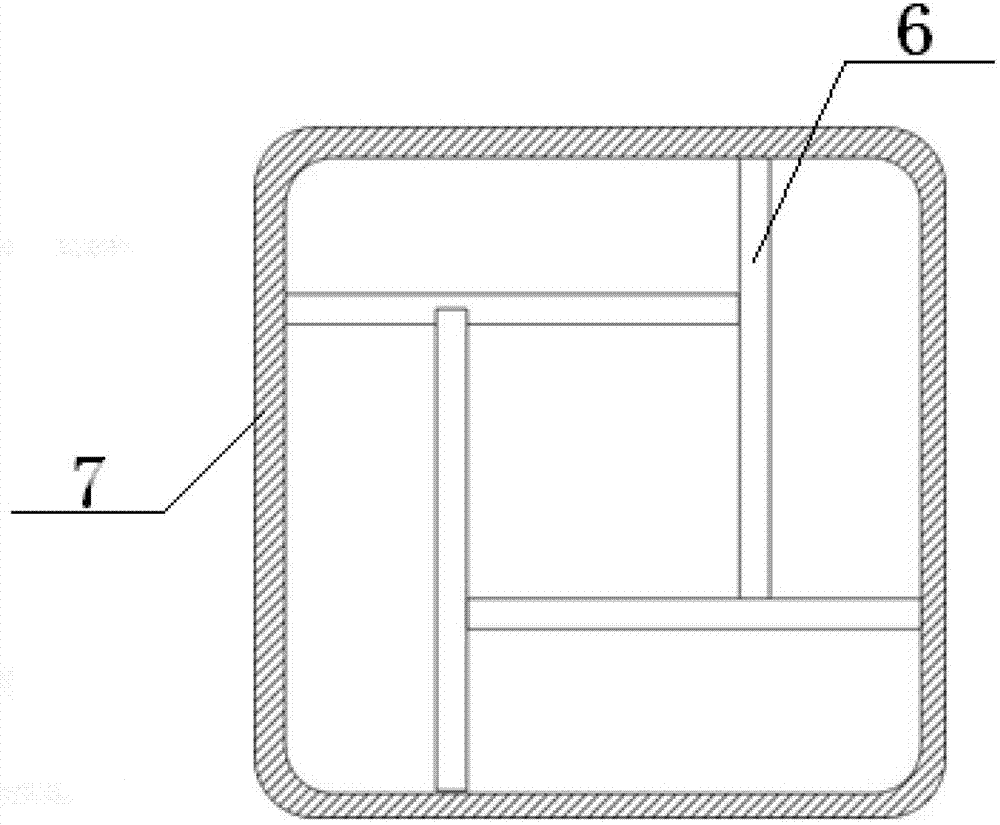

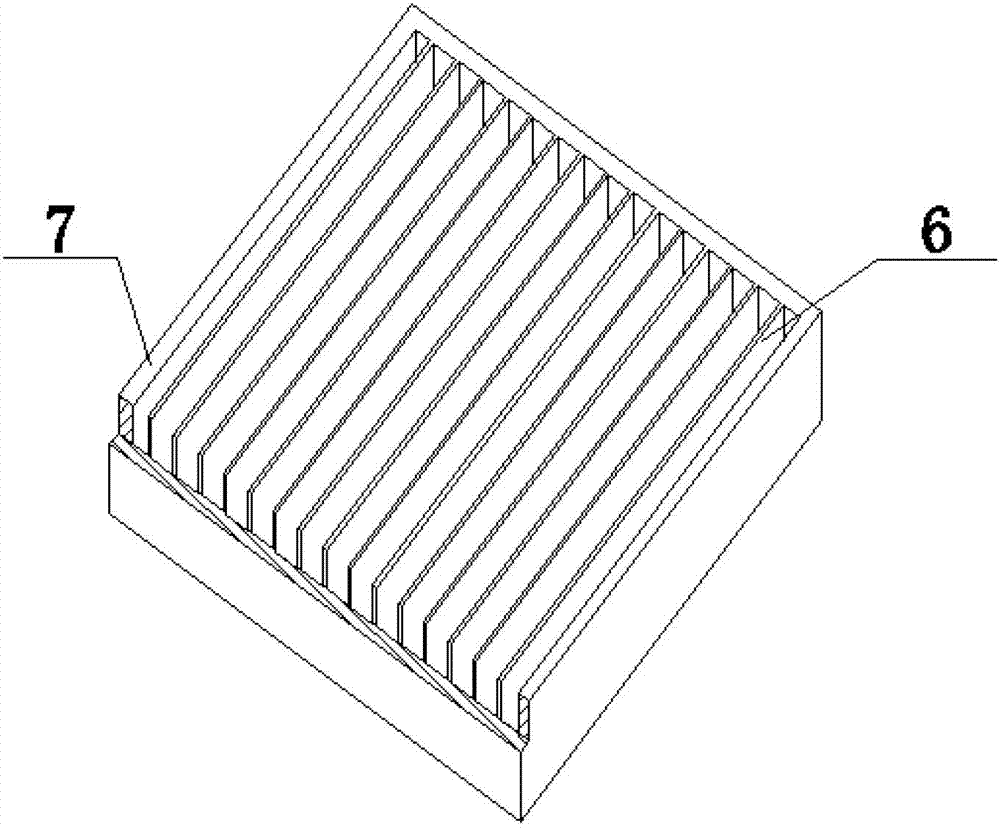

[0023] Such as figure 2 As shown, the connection between the cooling channel 4 and the cooled device 5 is provided with a heat exchange tube wall 7; inside the cooling channel 4 there are also 10 cooling fins 6.

[0024] The cold storage layer 2 adopts phase change cold storage; the phase change cold storage adopts ice storage.

[0025] The heat insulation layer 3 adopts a vacuum heat insulation layer.

[0026] The energy supply of the cooling layer 1 comes from the residual energy of the cooled device 5 .

[0027] The heat sink 6 is also provided...

Embodiment 2

[0028] Embodiment 2 of the present invention: as figure 1 As shown, a heat exchange system includes a refrigeration layer 1, a cold storage layer 2, a cooling channel 4 and a cooled device 5, the refrigeration layer 1 and the cold storage layer 2 are arranged below the cooled device 5, and the cold storage layer 2 is set Above the cooling layer 1 , an insulating layer 3 is provided on the outside of the cold storage layer 2 .

[0029] Such as figure 2 As shown, the connection between the cooling channel 4 and the cooled device 5 is provided with a heat exchange tube wall 7 ; inside the cooling channel 4 there are also 100 cooling fins 6 .

[0030] The cold storage layer 2 adopts phase change cold storage; the phase change cold storage adopts ice storage.

[0031] The heat insulation layer 3 adopts a vacuum heat insulation layer.

[0032] The energy supply of the cooling layer 1 comes from the residual energy of the cooled device 5 .

[0033] The heat sink 6 is also provi...

Embodiment 3

[0034] Embodiment 3 of the present invention: as figure 1 As shown, a heat exchange system includes a refrigeration layer 1, a cold storage layer 2, a cooling channel 4 and a cooled device 5, the refrigeration layer 1 and the cold storage layer 2 are arranged below the cooled device 5, and the cold storage layer 2 is set Above the cooling layer 1 , an insulating layer 3 is provided on the outside of the cold storage layer 2 .

[0035] Such as figure 2 As shown, the connection between the cooling channel 4 and the cooled device 5 is provided with a heat exchange tube wall 7; inside the cooling channel 4 there are also 1000 cooling fins 6.

[0036] The cold storage layer 2 adopts phase change cold storage; the phase change cold storage adopts ice storage.

[0037] The heat insulation layer 3 adopts a vacuum heat insulation layer.

[0038] The energy supply of the cooling layer 1 comes from the residual energy of the cooled device 5 .

[0039] The heat sink 6 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com