Measuring method and device for transmittance of optical element

A technology of optical components and measuring devices, applied in the field of laser measurement, to achieve the effect of eliminating repeatability, accurate and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

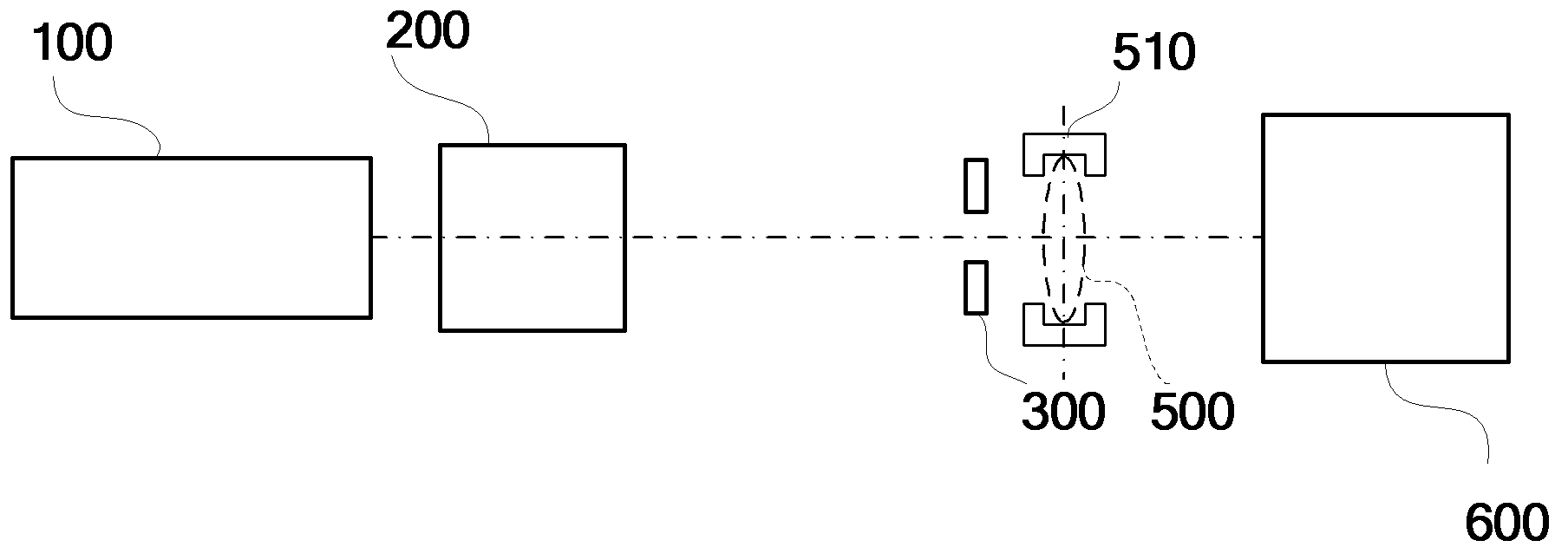

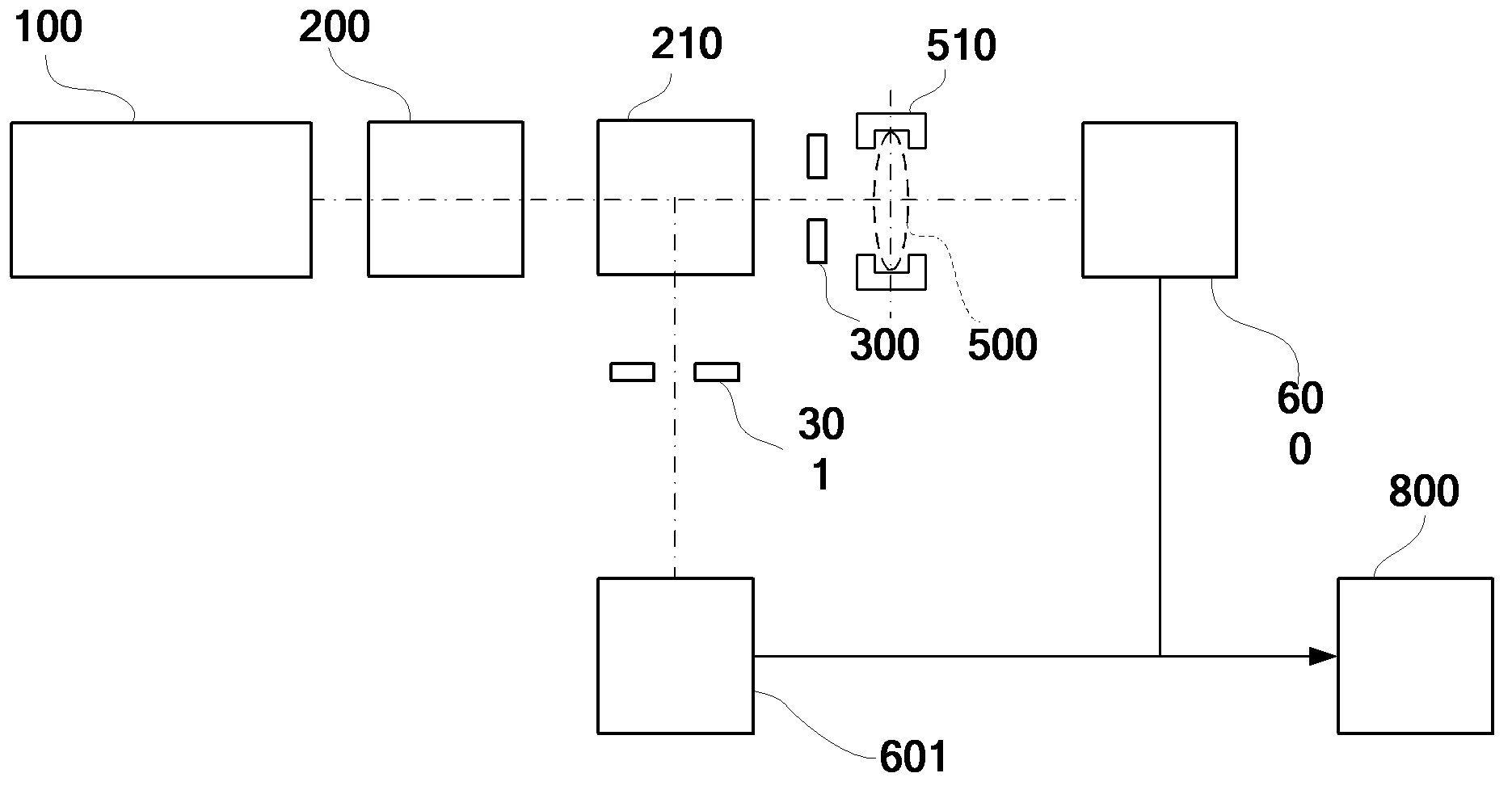

[0032] figure 2 It is a structural schematic diagram of the first embodiment of the optical element transmittance measurement device for high-energy, high-repetition-frequency ultraviolet pulse laser proposed by the present invention. Such as figure 2 As shown, the device is a dual optical path dual probe (photodetector) device, including a laser light source 100, an optical attenuator 200, a beam splitter 210, a first small hole plate 300, a second small hole plate 301, a Component holding device 510 , first photodetector 600 , second photodetector 601 and computer 800 . The optical element measured by the device of this embodiment is the lens 500 .

[0033] The laser light source 100 is an ultraviolet pulsed laser light source for generating ultraviolet pulsed laser light. The optical attenuator 200 is configured to receive the ultraviolet pulsed laser emitted by the laser light source 100 , and control the energy of the ultraviolet pulsed laser within the threshold ran...

no. 2 example

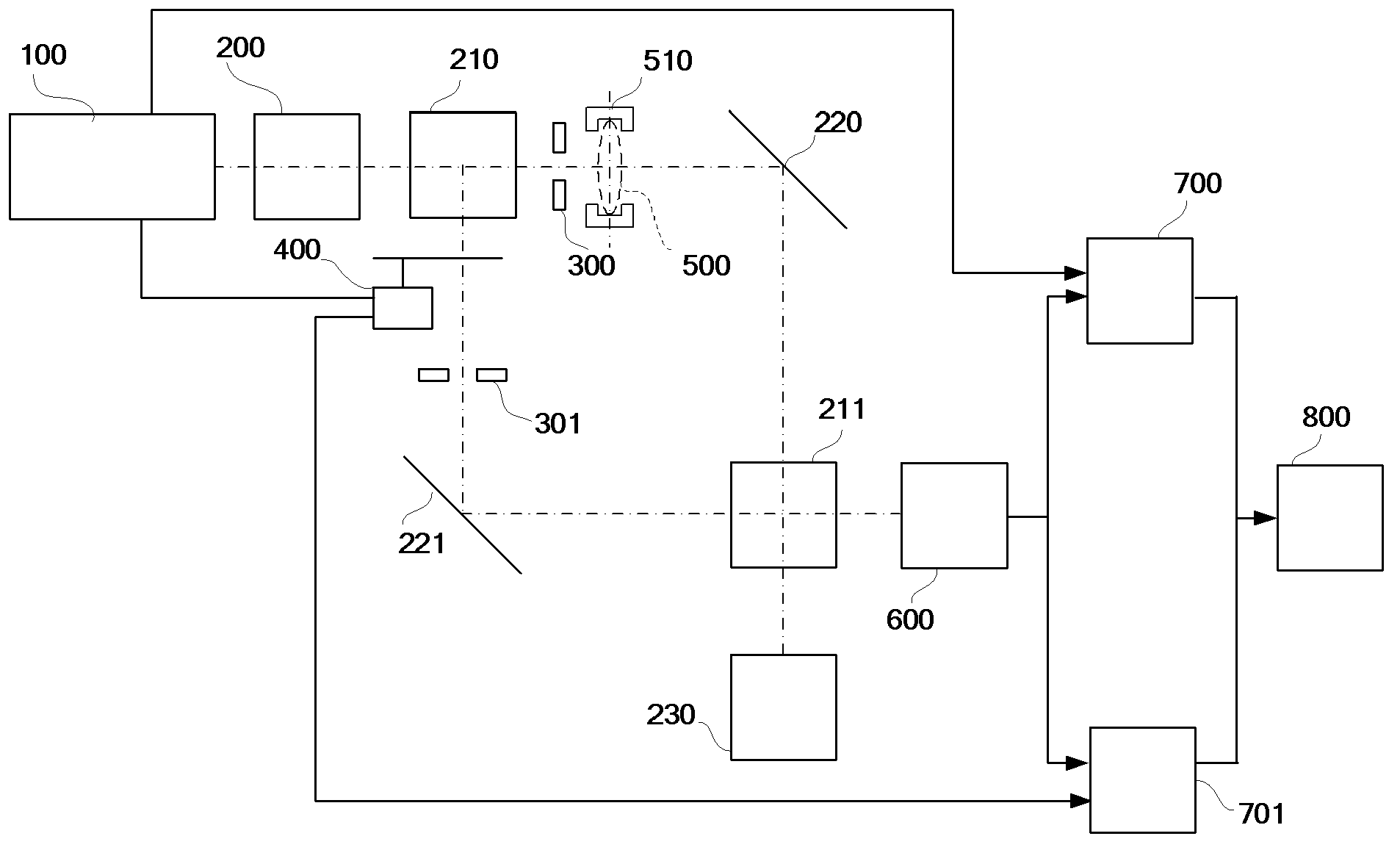

[0043] image 3 It is a structural schematic diagram of the second embodiment of the optical element transmittance measurement device for high-energy, high-repetition-frequency ultraviolet pulse laser proposed by the present invention. Such as image 3 As shown, the device is a dual optical path single probe (photodetector) device, including a laser light source 100, an optical attenuator 200, a beam splitter 210, a first small hole plate 300, a second small hole plate 301, an optical chopper Waveformer 400, first reflector 220, second reflector 221, beam splitter 211, beam collector 230, device under test clamping device 510, photodetector 600, first lock-in amplifier 700 and second lock-in amplifier amplifier 701 and computer 800. The optical element measured by the device of the second embodiment is also the lens 500 .

[0044] The laser light source 100 is an ultraviolet pulsed laser light source, which is used to generate 1 UV pulsed laser. At the same time, the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com