Stationary fixture used for axial compression stability test of columnar bent plate

A technology for stability testing and fixture fixing, applied in the directions of strength characteristics, measuring devices, instruments, etc., can solve the problems of difficult control of the curvature radius of cylindrical curved plates, assembly of specimens and fixtures, and unadjustable round cake chucks. Solve the problem of assembly and neutral adjustment, increase the adjustment margin, and achieve the effect of accurate boundary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

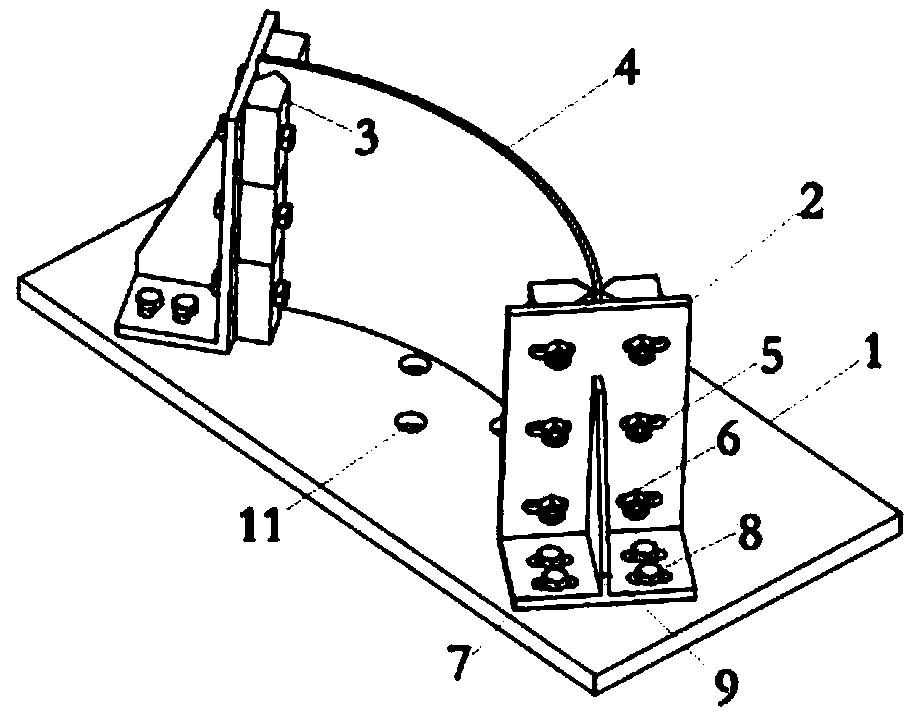

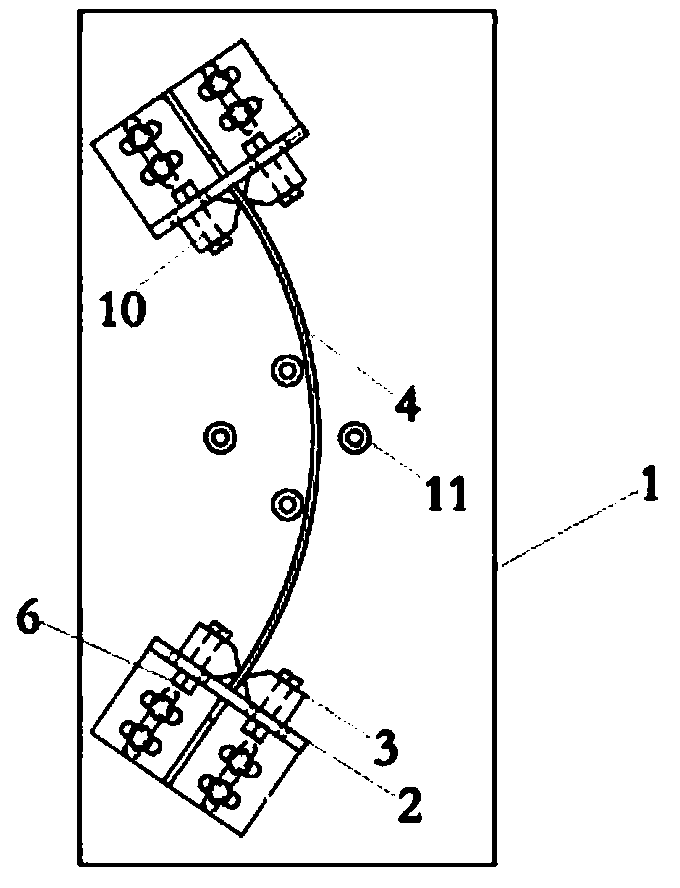

[0028] Such as figure 1 with figure 2 As shown, this embodiment includes: a lower platen 1, two L-shaped columns 2 and several pairs of chucks 3, wherein: the horizontal planes of the two L-shaped columns 2 are respectively fixed on the lower platen 1 and positioned at the bottom of the curved plate 4 to be measured. At the straight sides of the two ends, several pairs of chucks 3 are respectively fixed on the vertical plane along the straight sides of the two ends of the curved plate 4 to be tested, so that the straight sides of the two ends of the curved plate 4 to be tested are clamped on both sides Middle of chuck 3.

[0029] Fixing several pairs of chucks 3 in sections can overcome possible manufacturing errors of the curved plate 4 to be tested, such as warping.

[0030] A plurality of pairs of first position adjustment holes 5 are opened on the vertical surface of the L-shaped column 2 , and each chuck 3 is respectively fixed by the first connecting piece 6 in cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com