Photoelectric composite cable

A photoelectric composite cable and cable core technology, which is applied in the field of cables, can solve the problems such as the impossibility of producing large-diameter loose tubes, and achieve the effects of light weight, small outer diameter and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

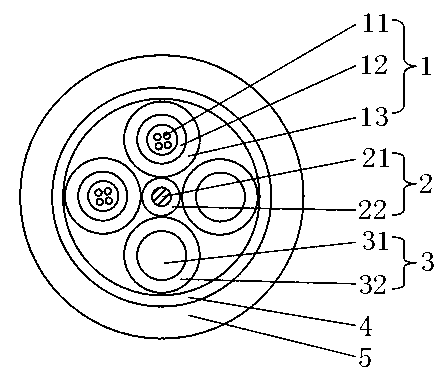

[0022] please see figure 1 , a photoelectric composite cable, which includes at least one optical unit 1, a strengthening member 2, at least two electrical units 3 and a sheath 5, the optical unit and the electrical unit are twisted around the strengthening member to form a cable core, and the sheath is located between the cable core In addition, the electrical unit is composed of a conductor 31 and an insulating layer 32 coated outside the conductor. It is characterized in that each optical unit consists of a plurality of optical fibers 11, a first protective layer 12 covering the optical fibers, and a first protective layer located on the first protective layer. The second protective layer 13 is formed outside the layer, and the diameter of the optical unit is the same as that of the electrical unit.

[0023] Of course, the above-mentioned photoelectric composite cable may also include filling ropes to replace the positions of some optical units.

Embodiment 2

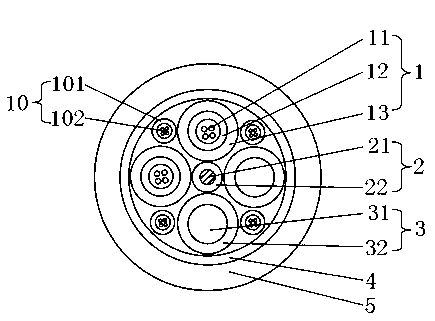

[0025] please see figure 2 , a photoelectric composite cable, which includes at least one optical unit 1, a strengthening member 2, at least two electrical units 3, a plurality of loose tubes 10 and a sheath 5, the optical unit, the loose tube and the electrical unit are twisted around the reinforcing member Combined to form a cable core, the sheath is located outside the cable core, the electrical unit is composed of a conductor 31 and an insulating layer 32 covering the conductor, and the loose tube is composed of an optical fiber 102 and a sleeve 101 covering the optical fiber. Each optical unit is composed of a plurality of optical fibers 11, a first protective layer 12 covering the optical fibers, and a second protective layer 13 outside the first protective layer; the diameter of the optical unit is the same as that of the electrical unit; The loose tube is located in the outer gap between the adjacent optical unit or the adjacent electrical unit or the adjacent optic...

Embodiment 3

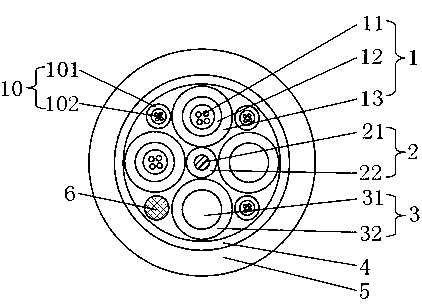

[0027] please see image 3 , and refer to figure 2 , a photoelectric composite cable, basically the same as the embodiment 2, except that a loose tube is replaced by a filler 6, and the size of the filler is the same as the diameter of the loose tube.

[0028] Certainly, it is also possible that a plurality of loose tubes are replaced by fillers 6 .

[0029] The photoelectric composite cable described in any of the above-mentioned implementation examples is characterized in that the reinforcement is composed of a reinforcement member 21 or a reinforcement member 21 and a bedding layer 22 extruded on the reinforcement member.

[0030] The photoelectric composite cable described in any of the above implementation examples is characterized in that there is a moisture barrier layer 4 between the cable core and the sheath.

[0031] The photoelectric composite cable described in any of the above implementation examples is characterized in that the optical fiber or opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com